0906-E

23

CONDENSING FANS CONTROL

Function

Maintain the condensing pressure as stable and as low as possible in order to increase the unit

performances, while avoiding excessive cycling.

Description

Identical to the complete machine control logic, the CLIMATIC

TM

50’s aim is to reach and hold the high

pressure set point. However the fan control includes a dead zone ensuring a greater stability to the High

Pressure and avoiding starting and stopping the fans too frequently.

Can be adjusted using menus

3611 = High pressure control set point in bars (relative pressure)

3612 = Reactivity

Operation

On a unit with N fans per circuit, the number of stages follows the table hereunder:

Number of Stages

Model PV with PWM PV GV

WA/RA

STD/HE/SLN

1 0 N-1

WA LN 1 N-1 0

Where: PV: Low speed Fan Operation

GV: High Speed Fan Operation

PWM: Pulse Width modulation (only on PV)

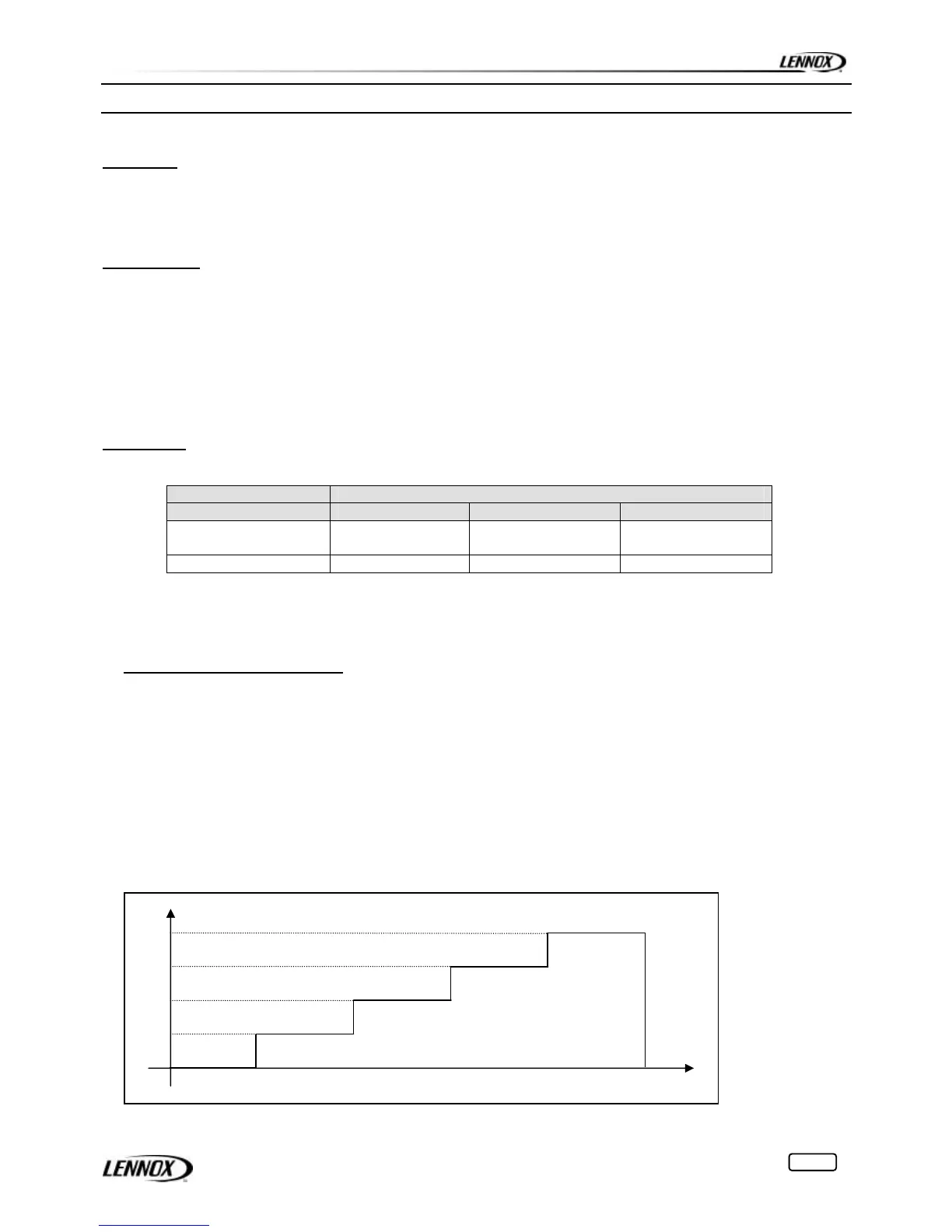

CASE 1 Unit without PV or PWM

The Ventilation Factor “V.F.” is calculated using the evolution of High Pressure (measured using the HP

sensor) and the rate at which it is moving away or towards the High Pressure Set Point (3611). See diagram

page 12.

It also includes a dead zone of 5 bars (4 bars if the unit has glycol and water set point <0°C) and a sampling

time constant of 15 seconds.

As for capacity control, the reactivity will fasten or slow down the VF evolution

Example: Unit with 3 fans, one circuit and HP set point 3611 is set to 15 bars

# Pressure > 15 bars ! V.F. increasing

# 10 bars < Pressure < 15 bars ! V.F. unchanged

# Pressure < 10 bars ! V.F. decreasing

25%

50%

100%

75%

Ventilation Facto