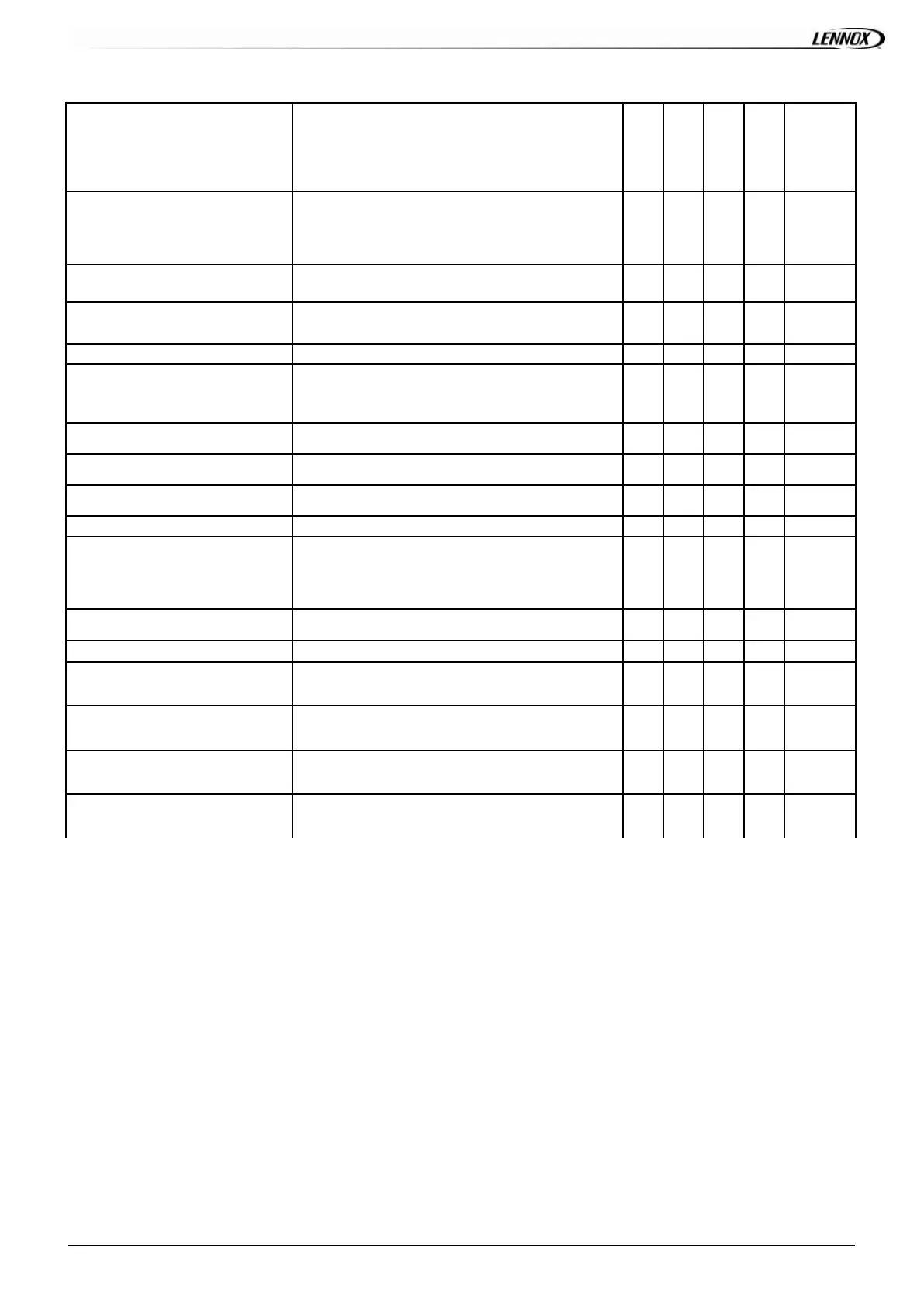

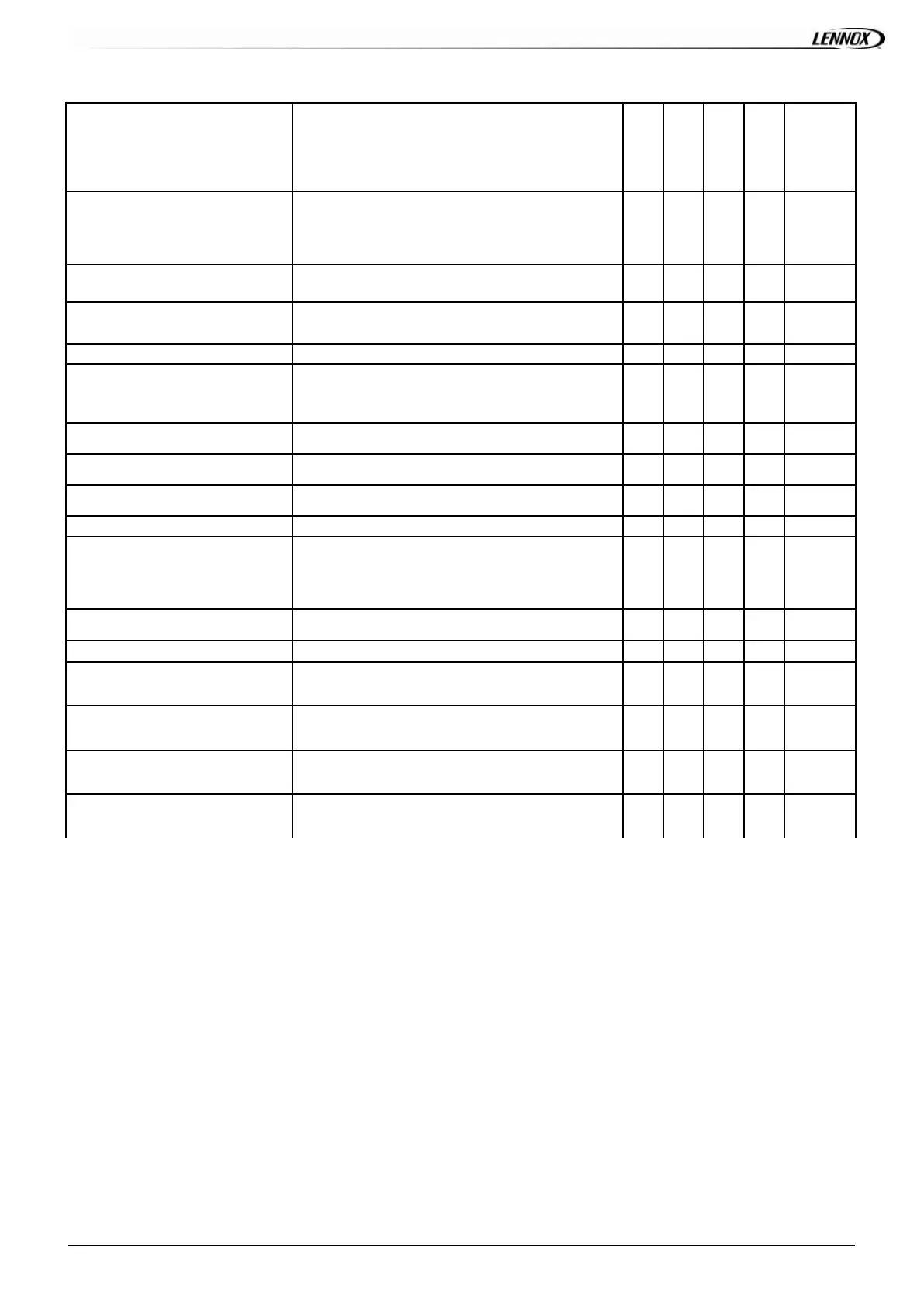

IOM – FLEXY II – 1007 – E Page 95

Task Operati ng mode

Monthly

Quarterly

6 m ont hly

Yearly B 4

winter

Estimated

Time

(min)

Clean or replace filters: Disposable, or

met al fr a me.

Replace filters with new ones if disposable. Vacuum clean

or blow t he dir t. W ash an d dry c aref ully. Re place media

if necessar y

Bloc ked filter will reduc e t he perf ormance of th e unit.

THE UNIT MUST NOT OPERATE WITHOUT FILTERS

o 20

Visual ch ec k of t he oil level

Visuall y chec k the oil level through the sight glass on the

side of the compressor casing

o 2

Position chec k of th e compressor

crankcase heater.

Chec k the heating resistance is fitted pr operl y and tight

aroun d t he c o mpress or bo d y.

o 2

Belt t ension ch ec k. Check belt tension (Info in IOM) Repl ace belt if necessar y.

o 10

Centrifugal fan bearings check

Isolate unit from t he main power s uppl y; Pus h the fan

wh eel ma nu al l y an d ch ec k f or a bnor mal noi ses . B ear ing s

are lubrica ted for life b ut may ne ed r eplacement after

100 00 ho ur s

o 10

Chec k absorbed Amps

Chec k absorbed Amps on all three phases; compare with

the nomin al value given i n the electrical wiring diagram.

[] 15

Chec k Smoke detector

Start t he unit . Trig ger the smo ke detect or b y movi ng a

mag net around the detector head. Reset unit and control.

[] 5

Chec k Climatic control, set-poin ts a nd

var i a bl es

Refer to the commissioning sheet; Check all set points are

set acc ording to this doc ument.

[] 15

Chec k cloc k settings Chec k the ti me and date o f t he c ontrol o 5

Chec k the position and tightness of

refrigeration components

Chec k systematicall y all c onnections and fi xings on the

refrigeration circuit. Check for oil traces, eventually a leak

test s houl d be conduct ed. C hec k operating press ures

correspond to the ones indicat ed on the commissioning

sheet

[] 30

Chec k Airflow rate s afety switc h (if

fitted).

Shut down su ppl y fan. T he f ault must be det ected withi n 5

seconds.

o

Chec k freeze protection on HWC [] 5

Chec k three way val ve on HWC

Increas e room s et-point 10°C above the actual room

temperature. Chec k operation of the piston. It must mo ve

awa y fr o m t he val ve he ad. Rese t th e c ontrol.

[] 5

Chec k economis er actuator operation

Chec k all fixings and transmission. Stop the unit using the

control. T he fresh air damper must cl ose. St art the unit the

fresh air damper should open

[] 5

Chec k refrigeration 4way val ve

With t he uni t run ni ng i n co oling mod e i ncr e ase the r oo m

set-point t em perat ure b y 1 0°C. T he unit s ho uld s witch to

hea t pump mode. Reset the control.

[] 5

Chec k tightness of all electrical

connections

Power down t he unit a nd c hec k and tighten all screws ,

termin al a nd electric connectio ns, t aking a particular

atte ntio n t o th e po wer lines a nd l ow volt ag e co ntr ol wires

O 30

Loading...

Loading...