3DJH

4. BCC Blower Control (A15)

-1 Through -4 Models

G23(X)-1, -2, -3 and -4 model units utilize the BCC blower

control manufactured by Heatcraft. See figure 10. The BCC

is a printed circuit board which controls the supply air blow-

er and monitors primary limit and gas valve operation. The

BCC is equipped with a jumper for electronic (isolation

relay) or electro-mechanical thermostat selection.The con-

trolhas a non-adjustable, factory preset fan “on” timing. Fan

“off” timing is adjustable. The board is divided into two sec-

tions, 120 and 24VAC. Line voltage comes into the board

on the 120VAC side. See table 1 for terminal designations.

Fan Timings

Fan “off” timing (time that the blower operates after the heat

demand has been satisfied) is determined by the arrange-

ment of a jumper across pins on the BCC blower control

board. See figure 9. To adjust fan“off” timing, gently discon-

nect jumper and reposition across pins corresponding with

new timing. Fan “on” time is factory set at 45 seconds andis

not adjustable.

NOTE—If fan “off” time is set too low, residual heat in

heat exchanger may cause primary limit S10 to trip re-

sulting in frequent cycling of blower. If this occurs, ad-

just blower to longer time setting.

Figure 9 shows the various fan “off” timings and how jumper

should be positioned. Unit is shipped with a factory fan “off”

setting of 90 seconds. Fan “off” time will affect comfort and

efficiency and is adjustable to satisfy individual applications.

The fan “off” timing is initiated after a heating demand but not

after a blower or cooling demand (that is, when indoor ther-

mostat switch is changed from ON to AUTO and heating/

cooling demand is not present, the blower stops immediate-

ly).

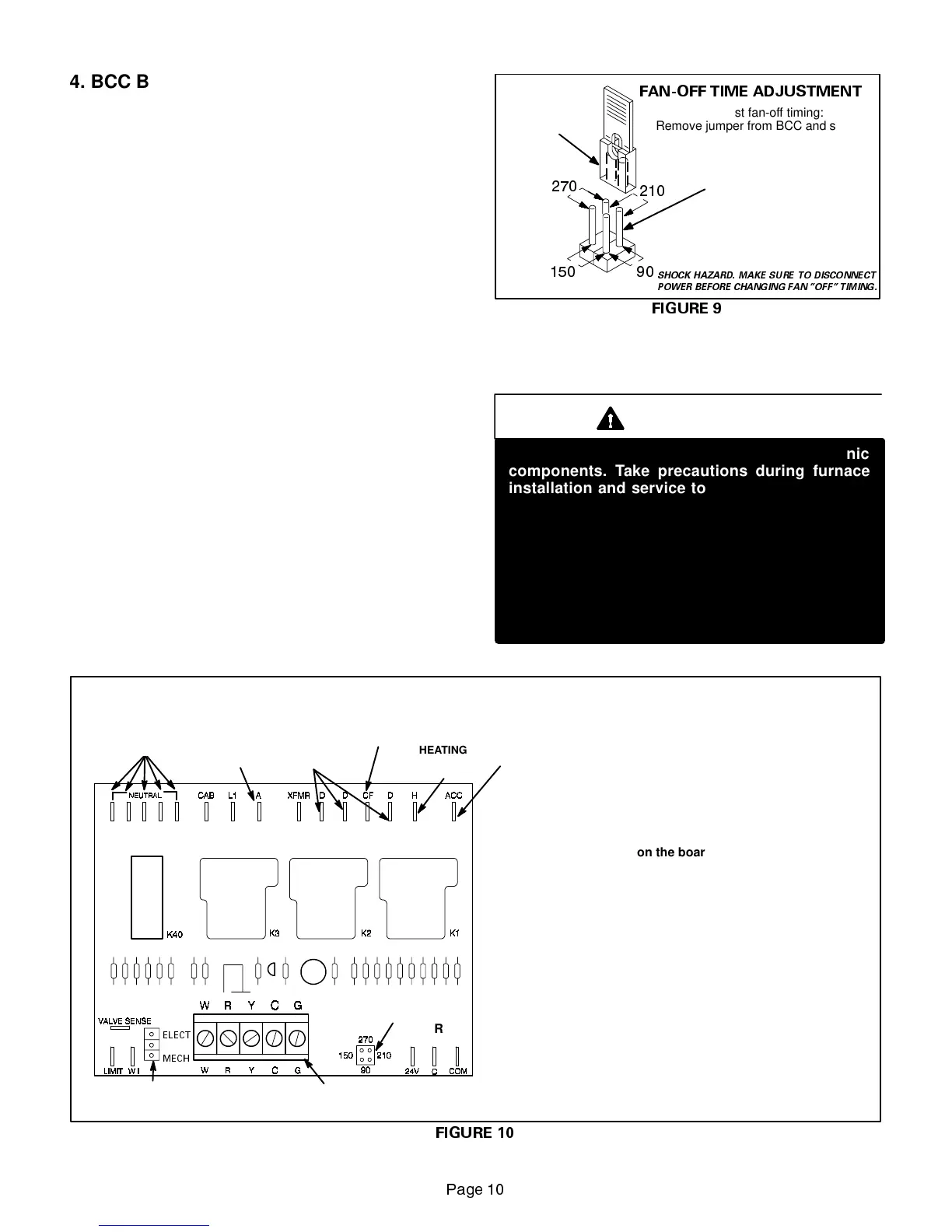

FIGURE 9

FAN-OFF TIME ADJUSTMENT

To adjust fan-off timing:

Remove jumper from BCC and select

one of the other pin combinations to

achieve the desired time.

TIMING

JUMPER

TIMING PINS

(seconds)

Leave jumper off for

330 second fan-off timing.

SHOCK HAZARD. MAKE SURE TO DISCONNECT

POWER BEFORE CHANGING FAN OFF TIMING.

CAUTION

Electrostatic discharge can affect electronic

components. Take precautions during furnace

installation and service to protect the furnace’s

electroniccontrols.Precautionswillhelpto avoid

control exposure to electrostatic discharge by

putting the furnace, the control and the techni-

cian at the same electrostatic potential. Neutral-

ize electrostatic charge by touching hand and all

tools on an unpainted unit surface, such as the

gas valve or blower deck, before performing any

service procedure.

ELECTROSTATIC DISCHARGE (ESD)

Precautions and Procedures

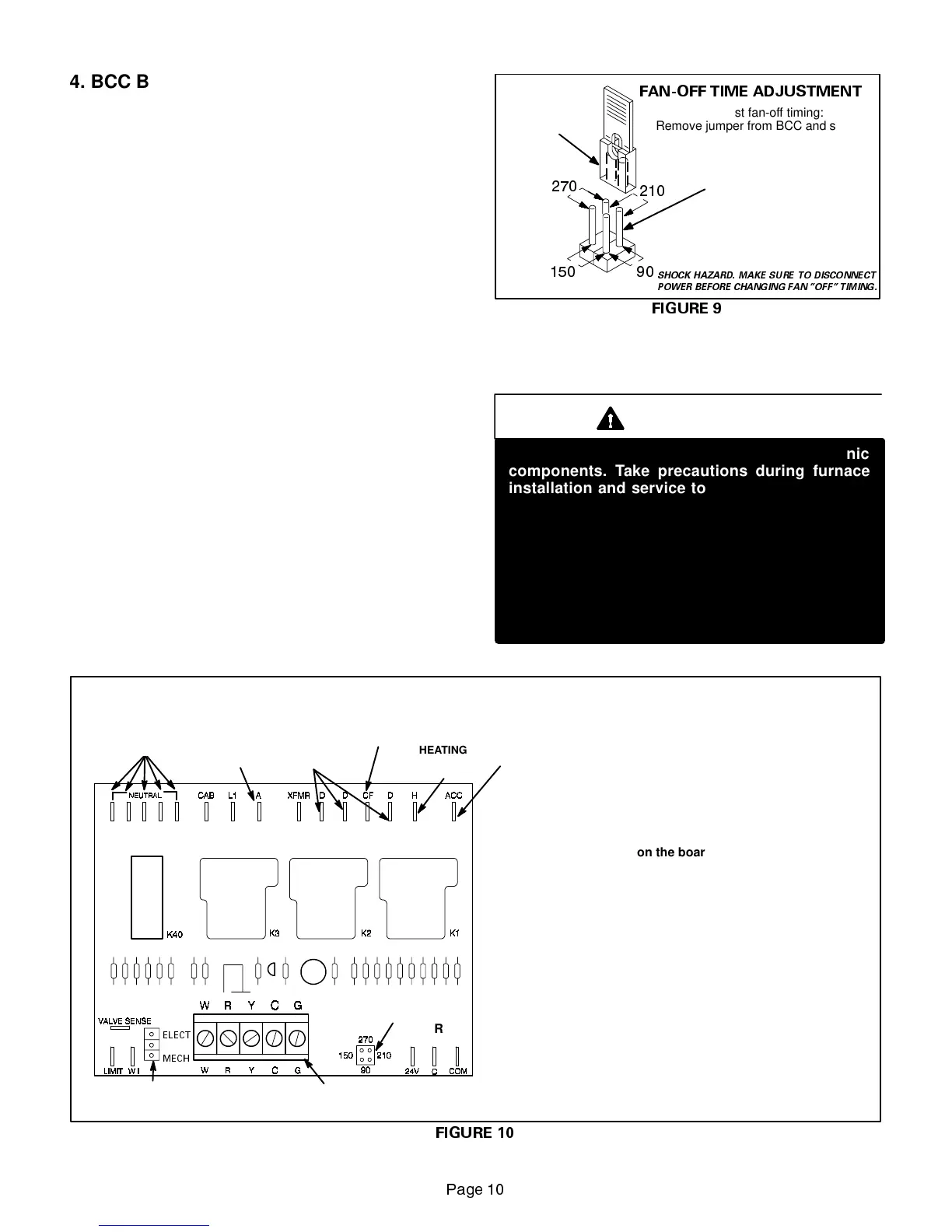

G23(X)-1, -2 ,-3 and -4 MODELS

BLOWER CONTROL - BCC

(A15)

FIGURE 10

NEUTRAL

TERMINALS

ACCESSORY

TERMINAL

THERMOSTAT TERMINAL STRIP

(DETACHABLE ON EARLY BOARDS ONLY))

BLOWER TIME

ADJUSTMENT

JUMPER

HEATING

SPEED TAP

TERMINAL

COOLING

SPEED TAP

TERMINAL

DUMMY

TERMINALS

CONTINUOUS FAN

TERMINAL

MECH

ELECT

THERMOSTAT JUMPER

(Electronic or Mechanical)

Heat Anticipator Settings

Beginning with the BCC3-2 series, a 3 pin jumper

has been installed on the board next to the remov-

able 24V terminal strip to account for both program-

mable and electromechanical thermostat usage in

the field. For electromechanical thermostat, position

the jumper over the middle and bottom pin labeled

”MECH.” Set the heat anticipator setting to 0.65

amps for Honeywell valves or 0.50 amps for White

Rodgers valves. For programmable (electronic) ther-

mostats, position the jumper over the middle and

top pin labeled ”ELECT.” Set the heat anticipator

setting to 0.1 amps.

Loading...

Loading...