3DJH

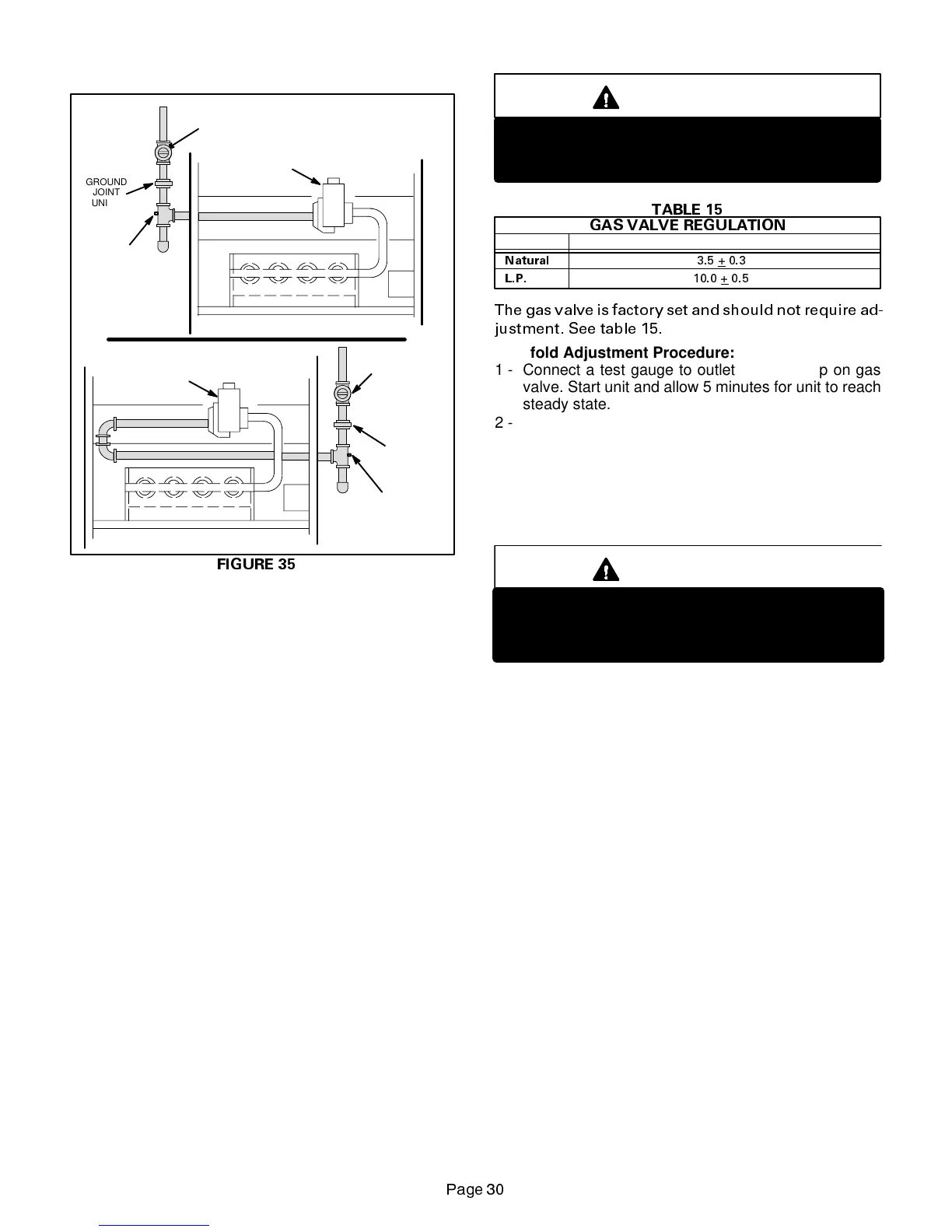

FIGURE 35

GROUND

JOINT

UNION

LEFT SIDE PIPING

(STANDARD)

RIGHT SIDE PIPING

AUTOMATIC

GAS VALVE

MANUAL

MAIN SHUT-OFF

VALVE

1/8” NPT

PLUGGED

TAP

GROUND

JOINT

UNION

MANUAL

MAIN SHUT-OFF

VALVE

1/8” NPT

PLUGGED

TAP

AUTOMATIC

GAS VALVE

When checkin

pipin

connections for

as leaks, use pre-

ferred means. Kitchen deter

ents can cause harmful corro-

sion on various metals used in

as pipin

. Use of a specialt

Gas Leak Detector is stron

l

recommended. It is available

throu

h Lennox under part number 31B2001. See Corp.

8411-L10, for further details.

Do not use matches, candles, flame or an

other source of

i

nition to check for

as leaks.

D-Check Manifold Pressure

After line pressurehas been checked and ad

usted, check

manifold pressure. Move pressure

au

etooutletpres-

sure tap located on unit

as valve

GV1

. Checks of man-

ifold pressure are made as verification of proper re

ulator

ad

ustment. Manifold pressure for the G23

X

can be mea-

sured at an

time the

as valve is open and is suppl

in

as

to the unit. Normal manifold pressure for natural

as units is

3.5 in. w.c. For LP

as the correct manifold pressure is 10.0

in. w.c.

IMPORTANT

For safety, connect a shut-off valve between the

manometer and the gas tap to permit shut off of

gas pressure to the manometer.

Operating Pressure (outlet) in. W.C.

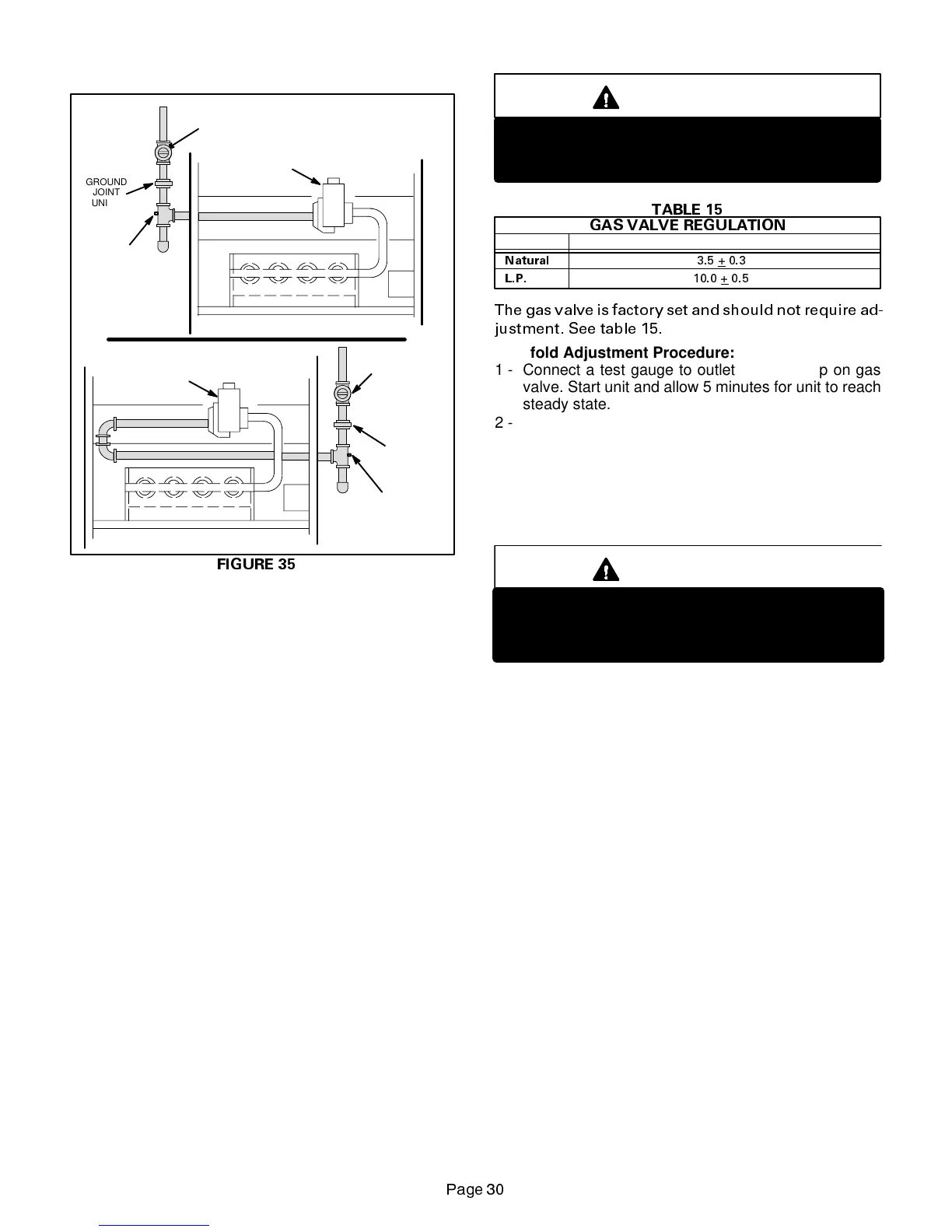

TABLE 15

GAS VALVE REGULATION

3.5 + 0.3

Natural

L.P.

10.0 +

0.5

Unit (Fuel)

The gas valve is factory set and should not require ad-

justment. See table 15.

Manifold Adjustment Procedure:

1 - Connect a test gauge to outlet pressure tap on gas

valve. Start unit and allow 5 minutes for unit to reach

steady state.

2 - While waiting for the unit to stabilize, notice the flame.

Flame should be stable and should not lift from burner.

Natural gas should burn blue. L.P. gas should burn

mostly blue with some orange streaks.

3 - After allowing unit to stabilize for 5 minutes, record

manifold pressure and compare to values given in

table 15.

IMPORTANT

For safety, shut unit off and remove manometer

as soon as an accurate reading has been ob-

tained. Take care to replace pressure tap plug.

E-Testing Gas Supply Pressure

When testing supply gas pressure, connect test gauge to

inlet pressure tap (field provided). See figure 35. Check

gas line pressure with unit firing at maximum rate. Low

pressure may result in erratic operation or underfire. High

pressure can result in permanent damage to gas valve or

overfire. For natural gas units, operating pressure at unit

gasconnectionmustbe between4.5” W.C.and 13.0”W.C.

For L.P. gas units, operating pressure at unit gas connec-

tion must be between 10.5” W.C. and 13.0” W.C.

On multiple unit installations, each unit should be checked

separately, with and without units operating. Supply pres-

sure must fall within range listed in previous paragraph.

Loading...

Loading...