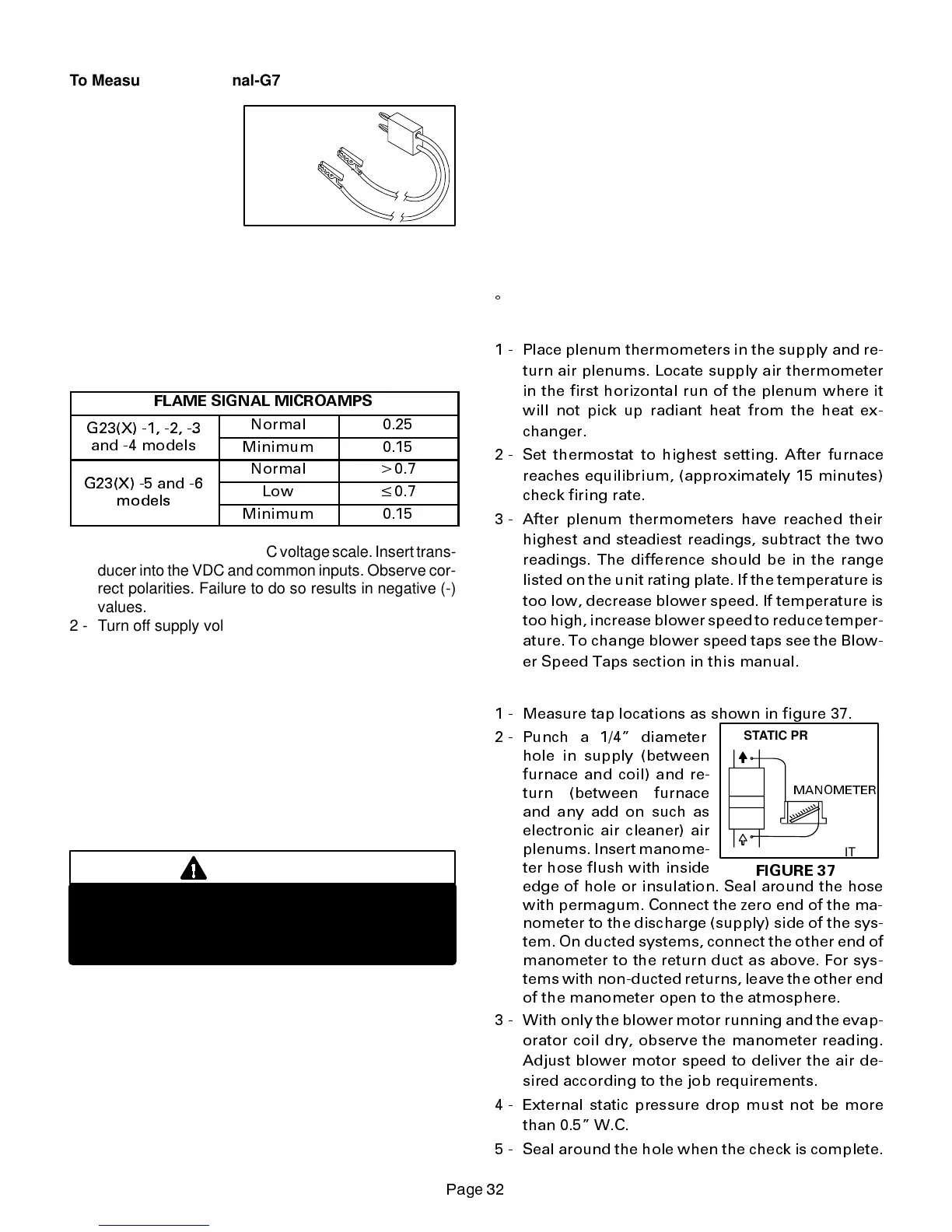

FIGURE 36

TRANSDUCER

(PART #78H5401)

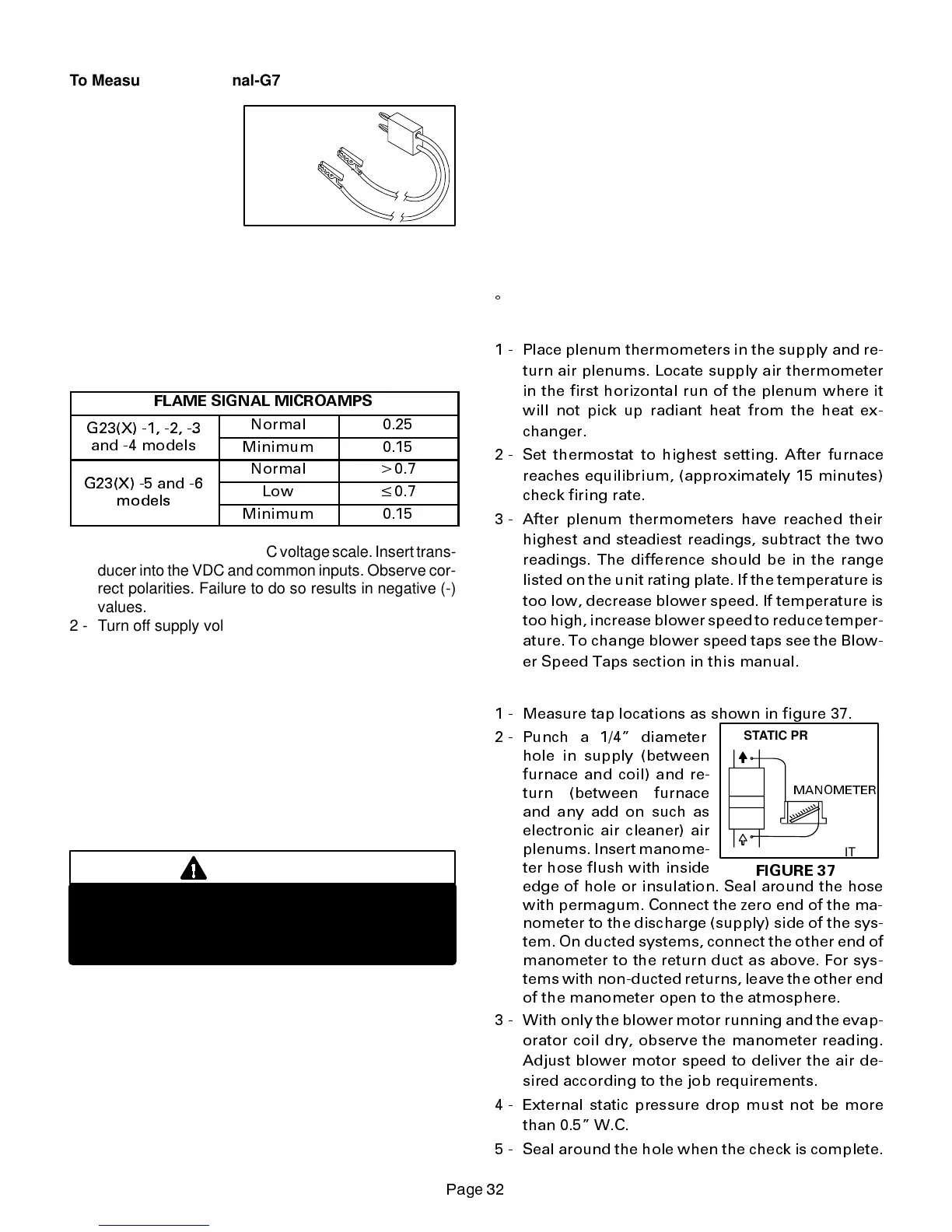

FIGURE 37

STATIC PRESSURE

TEST

MANOMETER

G23(X) UNIT

3DJH

To Measure Flame Signal-G776 Ignition Control:

A transducer (Part

#78H5401 available

from Lennox Repair

Parts) is required to

measure flame

signal. See figure 36.

The transducer converts

microamps to volts on a

1:1 conversion. If the flame signal should read 0.15-0.25

microamps, a reading of 0.15-0.25 volts should be read on

the meter. See table 19 for correct microamp reading.

A digital readout meter must be used. The transducer plugs

into most meters.

TABLE 19

FLAME SIGNAL MICROAMPS

G23(X) -1, -2, -3

Normal 0.25

,

,

and -4 models

Minimum 0.15

Normal

0.7

G23(X) -5 and -6

Low

$

0.7

Minimum 0.15

1 - Setthevolt meter tothe DCvoltagescale.Inserttrans-

ducer into the VDC and common inputs. Observe cor-

rect polarities. Failure to do so results in negative (-)

values.

2 - Turn off supply voltage to control.

3 - Disconnect flame sensor lead from terminal of ignition

control.

4 - Connect (+) lead of transducer to ignition control sen-

sor connection.

5 - Connect (-) lead of the transducer to sensor wire.

6 - Turn supply voltage on and close thermostat contacts

to cycle system.

7 - When unit lights read voltage on meter display. Re-

member 1 DC volt = 1 DC microamp. See table 19 for

correct microamp reading.

WARNING

Fire and explosion hazard.

These instructions MUST be followed exactly.

Can causea fire orexplosion resulting in property

damage, personal injury or loss of life.

Flame signal may rise above 0.5 microamps for the first

few seconds after ignition and then level off within the

range.

V-TYPICAL OPERATING CHARACTERISTICS

A-Blower Operation and Adjustment

NOTE- The following is a generalized procedure and

does not apply to all thermostat controls.

1 - Blower operation is dependent on thermostat control

system.

2 - Generally, blower operation is set at thermostat sub-

base fan switch. With fan switch in ON position, blower

operates continuously. With fan switch in AUTO posi-

tion, blower cycles with demand or runs continuously

while heating or cooling circuit cycles.

3 - In all cases, blower and entire unit will be off when the

system switch is in OFF position.

B-Temperature Rise

Temperature rise for G23(X) units depends on unit input,

blower speed, blower horsepower and static pressure as

marked onthe unit rating plate. The blower speed must be

set for unitoperationwithin therangeof “AIRTEMP. RISE

q

F” listed on the unit rating plate.

To Measure Temperature Rise:

1 - Place plenum thermometers in the supply and re-

turn air plenums. Locate supply air thermometer

in the first horizontal run of the plenum where it

will not pick up radiant heat from the heat ex-

changer.

2 - Set thermostat to highest setting. After furnace

reaches equilibrium, (approximately 15 minutes)

check firing rate.

3 - After plenum thermometers have reached their

highest and steadiest readings, subtract the two

readings. The difference should be in the range

listed on the unit rating plate. If the temperature is

too low, decrease blower speed. If temperature is

too high, increase blower speed to reduce temper-

ature. To change blower speed taps see the Blow-

er Speed Taps section in this manual.

C-External Static Pressure

1 - Measure tap locations as shown in figure 37.

2 - Punch a 1/4 diameter

hole in supply (between

furnace and coil) and re-

turn (between furnace

and any add on such as

electronic air cleaner) air

plenums. Insert manome-

ter hose flush with inside

edge of hole or insulation. Seal around the hose

with permagum. Connect the zero end of the ma-

nometer to the discharge (supply) side of the sys-

tem. On ducted systems, connect the other end of

manometer to the return duct as above. For sys-

tems with non-ducted returns, leave the other end

of the manometer open to the atmosphere.

3 - With only the blower motor running and the evap-

orator coil dry, observe the manometer reading.

Adjust blower motor speed to deliver the air de-

sired according to the job requirements.

4 - External static pressure drop must not be more

than 0.5 W.C.

5 - Seal around the hole when the check is complete.

Loading...

Loading...