Page 16

Diagnostic LED

The furnace control is equipped with a diagnostic LED

used for troubleshooting the unit and the control. LED

functions are shown in table 7.

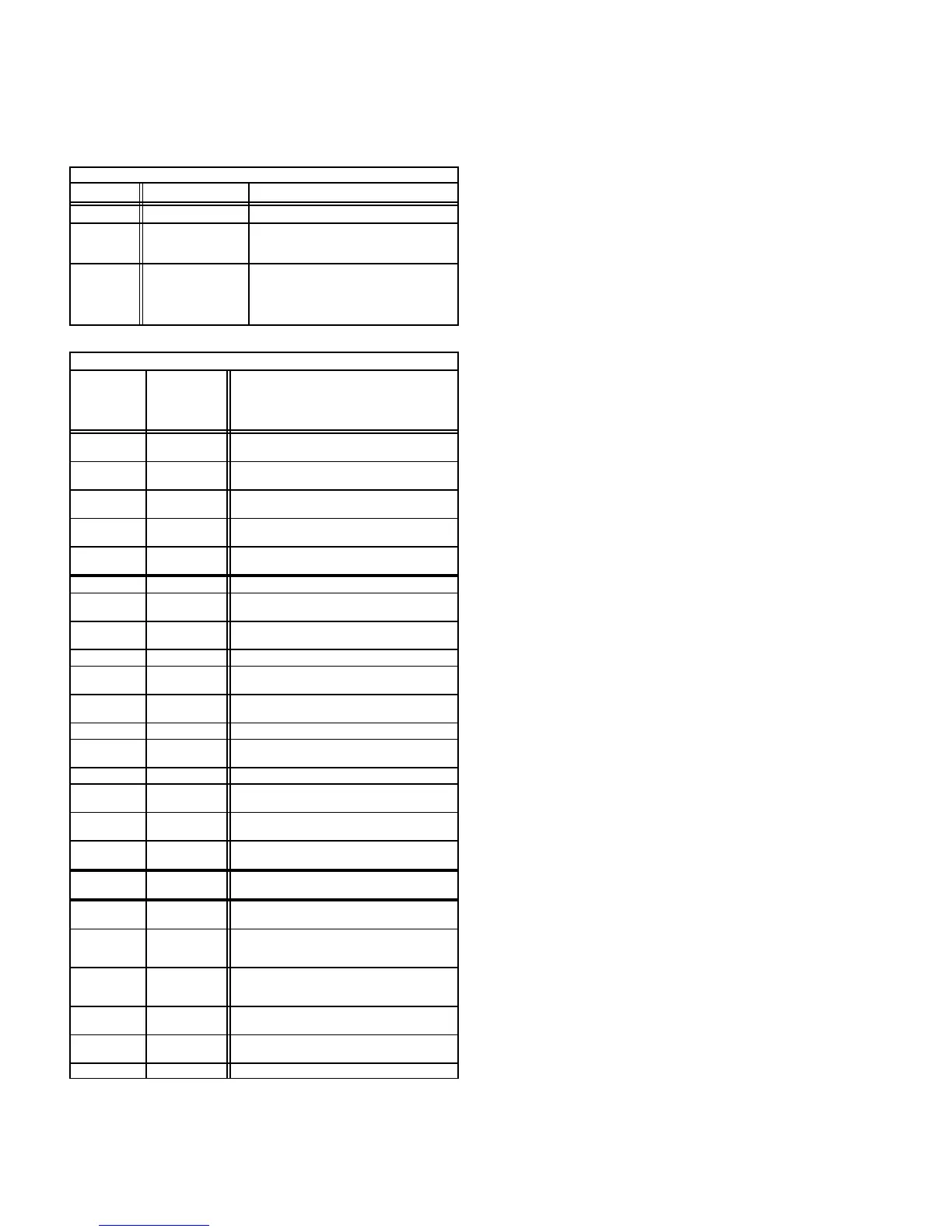

TABLE 7

Furnace Control A3 Diagnostic LED

LED State Meaning Remedy

Steady On Normal Operation - - - -

Slow Flash

(1 sec. on/

5 sec. off)

Control Retry

Period

Failed to Sense Flame. Ignition Con-

trol Will Retry

Before Locking Out.

Off

Control Failure or

Power Failure or

Hard Lockout

If Power and Gas Supply are OK, Try

Removing T’stat Demand For At Least

30 Seconds. If LED Remains Off

When Demand Is Returned, Replace

Control.

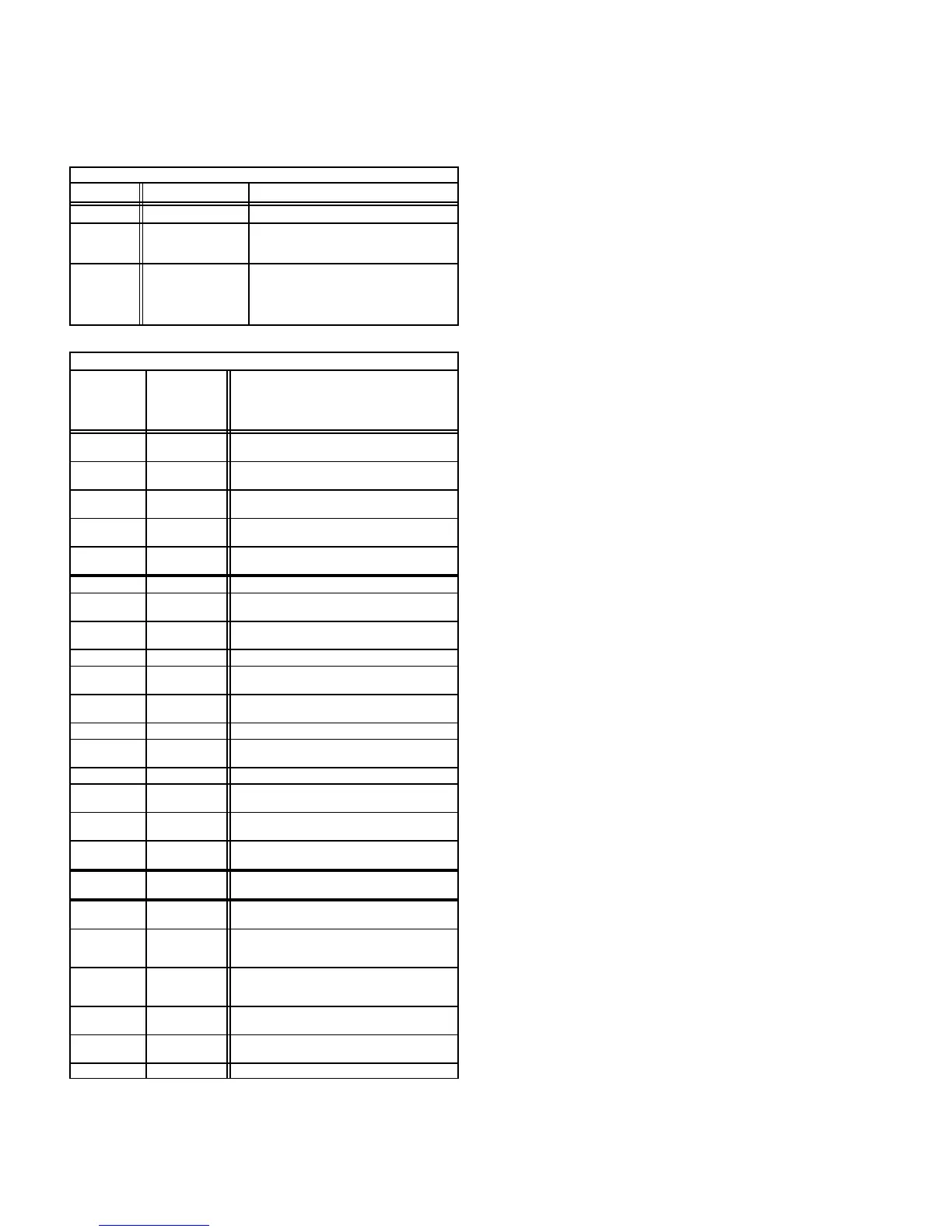

TABLE 8

BLOWER CONTROL A15 TERMINAL DESIGNATIONS

Terminal

(Designation

on Wiring

Diagram)

Type Function

Y

Detachable

Screw Strip

Cooling Demand

G

Detachable

Screw Strip

Blower Demand

R

Detachable

Screw Strip

24VAC to Thermostat

W

Detachable

Screw Strip

Heating Demand

T

Detachable

Screw Strip

24VAC Common

To Indoor Thermostat

IBN (N) 1/4" Spade 120VAC Indoor Blower Common

N1 (N) 1/4" Spade

120VAC Neutral

(L2 Line Voltage Neutral)

CABN (N) 1/4" Spade

120VAC Combustion Air Blower Com-

mon

XFMRN(N) 1/4" Spade 120VAC Transformer Common

HSIN (N) 1/4" Spade

120VAC Hot Surface Ignition

Common (Not Used)

CAB 1/4" Spade

Switched 120VAC to

Combustion Air Blower

L1 1/4" Spade 120VAC Line Voltage In

A 1/4" Spade

Switched 120VAC

to Blower Cooling Tap

XFMR 1/4" Spade 24VAC In From Transformer

D 1/4" Spade

Dummy Connection for

Unused Blower Leads

CF 1/4" Spade

Switched 120VAC to

Continuous Blower Tap

H 1/4" Spade

Switched 120VAC to

Blower Heating Tap

ACC 1/4" Spade

Switched 120VAC to Accessory (Elec-

tronic Air Cleaner, Humidifier, Etc.)

24V

(24)

1/4" Spade 24VAC Input From Transformer

LIMIT

(L)

1/4" Spade

24VAC In From Primary Limit. Limit

Open: Closes Gas Valve and Turns On

Blower Limit Closed: Allows Ignition

W 1/4" Spade

24VAC Thermostat Demand Output

Through Differential Switch to THS"

Terminal of Ignition Control

VALVE

SENSE (V)

3/16" Spade 24VAC Input From Gas Valve

T 1/4" Spade

24VAC Common From

Ignition Control and Gas Valve

COM (C) 1/4" Spade 24VAC Common To Transformer

Johnson G776 Ignition Control Operation

The information in this section is protected by a copyright issued by

Johnson Controls, Inc., and is reproduced with permission.

On a call for heat from indoor thermostat, the ignition control

energizes and ignition control LED lights (steady on). The

combustion air blower is energized. After 15 second pre-

purge period, the control simultaneously opens pilot valve

and sends spark to pilot electrode.

If pilot ignites within 85 seconds, flame sensor detects pilot

flame and signals ignition control to energize the main

valve. The main valve cannot be energized until sensor

detects pilot flame. Spark continues until pilot flame is

sensed or 85 seconds has elapsed.

When pilot flame is sensed, main valve is energized and

spark turns off. The ignition control remains in run" mode un-

til indoor thermostat is satisfied or flame lost.

If pilot flame is not sensed before the end of the 85 second trial

for ignition, the control enters the 100% shutoff mode. The

spark circuit and pilot valve de-energize and the ignition con-

trol automatically begins the 60 minute retry delay period.

During the 60 minute delay the diagnostic LED continually

flashes on for one second and off for five seconds. After the

delay period, another trial for ignition sequence starts, begin-

ning with pre-purge.

If pilot flame goes out while the indoor thermostat is calling

for heat, both main and pilot valves de-energize within 0.8

seconds and remain de-energized for five seconds. After

this delay, the spark and pilot valve energize until flame is

sensed or the 85 second trial for ignition period ends. If this

flameout" cycle repeats 16 times (pilot flame is estab-

lished and then lost), the control locks out and the LED

goes off. A new trial for ignition sequence begins after the

thermostat contacts are opened for 2 seconds and then

closed.

If flame is detected when the thermostat calls for heat, it

must extinguish within 30 seconds for normal operation. If

flame is still present after 30 seconds, the control goes into

lockout and the LED goes off.

13−Pilot, Spark Electrode, Flame Sensor

(−1 and −2 models)

Figure 18 shows the arrangement of pilot, flame sensor,

spark electrode and burners. The ignition control uses di-

rect spark to ignite the pilot. The pilot ignites the burners

and the burners cross-light. The flame sensor uses flame

rectification to sense pilot ignition. The ignition control re-

quires that pilot flame must be sensed before the main gas

valve is allowed to open. Typically, a 2 to 4 second delay

occurs between the pilot ignition and the main valve open-

ing. Figure 19 shows the gap between the tip of the elec-

trodes and the burner surface. It is important that the gap

be maintained for consistent ignition of pilot flame.

Loading...

Loading...