Page 20

TABLE 13

VSP FACTORY SETTINGS FOR G32V−4 UNITS

MODEL

NUMBER

DELAY COOL ADJUST HEAT

G32V3−75 4 4 NORM 3

G32V5−100 4 4 NORM 2

G32V5−125 4 4 " 4

NOTE − In Harmony II zoning applications in the heating mode, the

highest cooling speed selected is the highest blower speed ob-

tainable. Also, the fan−only speed is used when the primary limit

has been tripped. In non−zoning applications, refer to the section

on the VSP3−1 control.

ADJUST

The ADJUST pins allow the motor to run at normal speed or

approximately 15% lower than normal speed. Blower

tables and the front of this manualgive two rows (NORMAL

and −) with their respective CFM volumes. The + adjust-

ment setting is not operable. Notice that the normal adjust-

ment setting for heat speed position #3 is 2030 CFM (955

L/s) in table 4. After the adjustment setting has been deter-

mined, choose the remainder speed jumper settings from

those in the table.

The TEST pin is available to bypass the VSP3−1 control and

run the motor at approximately 70% to test that the motor is

operational. This is beneficial primarily in troubleshooting. G

must be energized for motor to run.

HTG. BLOWER

For G32V−4 units only, place the HTG. BLOWER jumper

across the second and third pins (position #2).

NOTE − In Harmony II zoning applications, HTG. BLOWER

jumper must be in position #2.

HEAT

The HEAT jumper is used to set the blower speed to obtain

the required CFM as outlined in HEAT SPEED section of

tables 3 and 4.

The HEAT jumper selections are activated with a call for

first−stage heating (W1) and second−stage heating (W2).

DELAY

The DELAY jumper is used to set the specific motor fan

mode of operation during cooling. Depending on the ap-

plication, one of four fan options may be chosen by moving

the jumper to the appropriate set of pins.

Options 1, 2, 3, or 4 will have an increased dehumidification

effect on the system. Option 1 will have the least effect and

option 4 will have the greatest effect.

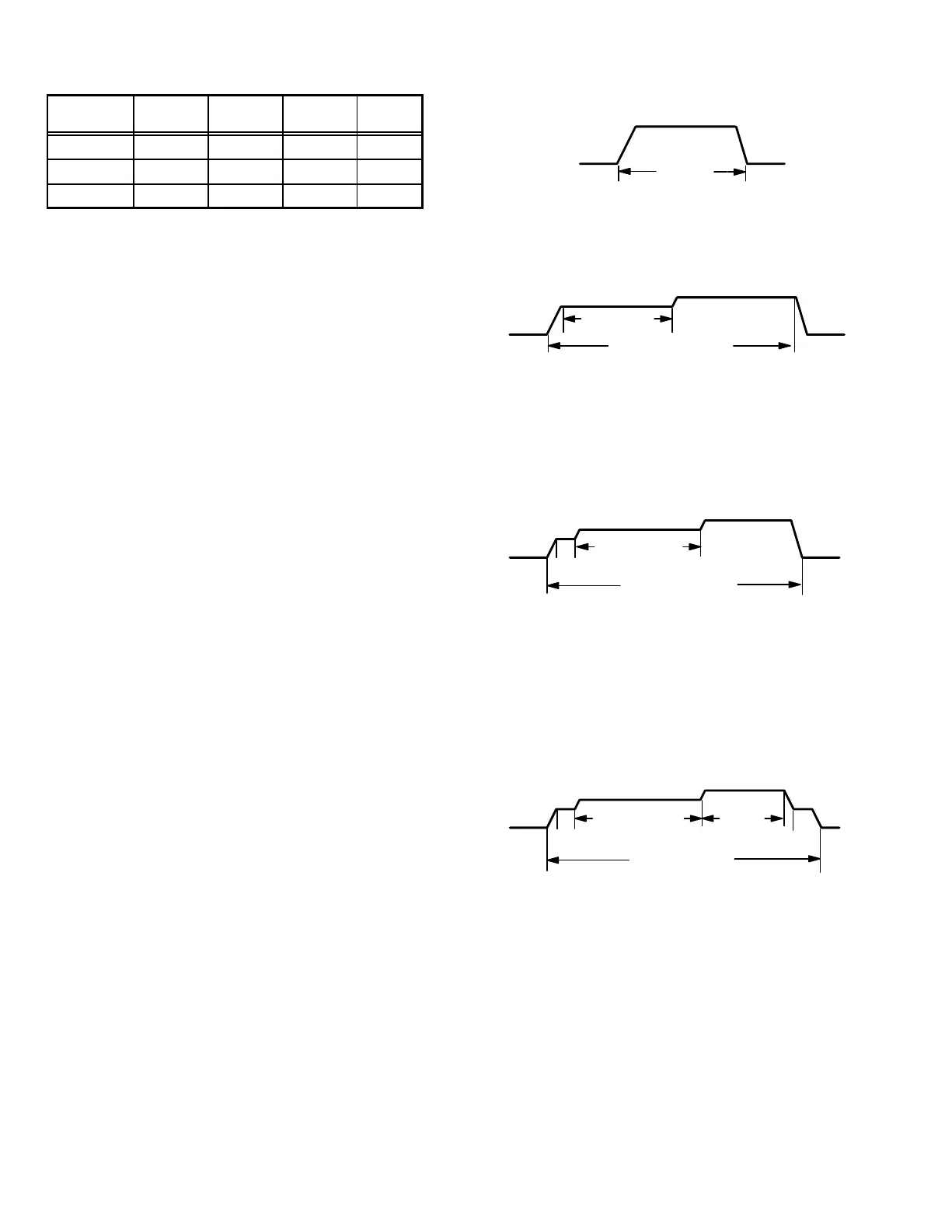

#1 PIN JUMPERED

A − Motor runs at 100% until demand is satisfied.

B − Once demand is met, motor ramps down to off.

OFFOFF

A B

100% CFM

COOLING

DEMAND

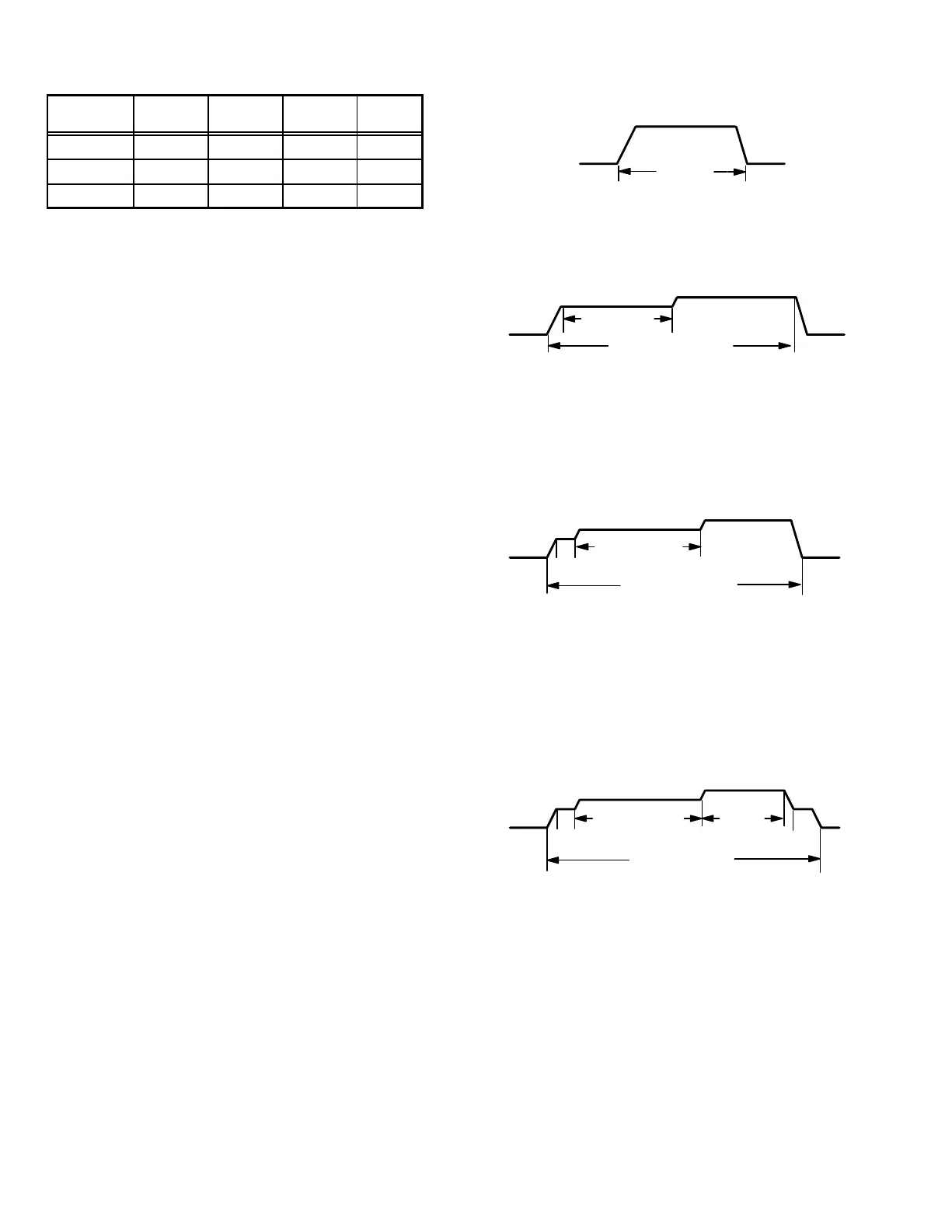

#2 PIN JUMPERED

A − Motor runs at 82% for approximately 7−1/2 minutes.

B − If demand has not been satisfied after 7−1/2 minutes,

the motor runs at 100% until demand is satisfied.

C − Once demand is met, motor ramps down to off.

OFF

OFF

A

B

C

82%CFM

100% CFM

COOLING DEMAND

7 1/2 MIN

#3 PIN JUMPERED

A − Motor runs at 50% for 1/2 minute.

B − Motor then runs at 82% for approximately 7−1/2 min-

utes.

C − If demand has not been satisfied after 7−1/2 minutes,

motor runs at 100% until demand is satisfied.

D − Once demand is met, motor ramps down to off.

A

B

OFF

OFF

C D

1/2 MIN

50% CFM

7 1/2 MIN

82% CFM

100% CFM

COOLING DEMAND

#4 PIN JUMPERED

A − Motor runs at 50% for 1/2 minute.

B − Motor then runs at 82% for approximately 7−1/2 min-

utes.

C − If demand has not been satisfied after 7−1/2 minutes,

motor runs at 100% until demand is satisfied.

D − Once demand is met, motor runs at 50% for 1/2 min-

ute.

E − Motor ramps down to off.

A

B

OFF

OFF

C D

E

1/2 MIN

50% CFM

COOLING DEMAND

7 1/2 MIN

82% CFM

100%

CFM

1/2 MIN

50% CFM

COOL

The cool jumper is used to set the blower speed to obtain

the required CFM as outlined in tables 3 and 4.

VSP Operation

Table 14 and 15 outline the operation of the variable speed

motor in relation to specific modes of operation. Some infor-

mation has been repeated from the previous section to pro-

vide an example. Refer to each diagnostic LED or jumper

settings section for more information.

Loading...

Loading...