Page 14

Vent Piping Guidelines

The G43UF can be installed as either a Non−Direct Vent

or a Direct Vent gas central furnace.

NOTE − In Non-Direct Vent installations, combustion air is

taken from indoors and flue gases are discharged outdoors.

In Direct Vent installations, combustion air is taken from out-

doors and flue gases are discharged outdoors.

Intake and exhaust pipe sizing in Direct Vent applications

and exhaust pipe sizing in Non-Direct Vent applications −−

Size pipe according to tables 4 and 5. Table 4 lists the mini-

mum equivalent vent pipe lengths permitted. Table 5 lists

the maximum equivalent pipe lengths permitted.

Maximum vent length is defined as:

Total length (linear feet) of pipe,

Plus Equivalent length (feet) of fittings,

Plus Equivalent length (feet) of termination.

NOTE − Include ALL pipe and ALL fittings, both

indoors and outdoors.

Regardless of the diameter of pipe used, the standard roof

and wall terminations described in section Exhaust Piping

Terminations should be used. Exhaust vent termination

pipe is sized to optimize the velocity of the exhaust gas as

it exits the termination. Refer to table 6.

NOTE − The exhaust pipe should be offset a minimum of 12

inches to avoid the possibility of water droplets being re-

leased from the exhaust termination. The minimum ex-

haust vent length is 15 ft. Shorter exhaust vent lengths may

result in the discharge of water droplets from the exhaust

termination, in spite of the 12−inch vertical offset.

Each 90° elbow (including those provided with the furnace)

of any diameter is equivalent to 5 feet (1.52m) of vent pipe

of the same diameter. Two 45° elbows are equivalent to

one 90° elbow of the same diameter. One 45° elbow is

equal to 2.5 feet (.76m) of vent pipe of the same diameter.

In some applications which permit the use of several differ-

ent sizes of vent pipe, a combination vent pipe may be

used. Contact the Application Department for assistance in

sizing vent pipe in these applications.

NOTE − The flue collar on all models is sized to accommo-

date 2" Schedule 40 flue pipe. When vent pipe which is

larger than 2" must be used in an upflow application, a 2"

elbow must be applied at the flue collar in order to proper-

ly transition to the larger diameter flue pipe. This elbow

must be added to the elbow count used to determine ac-

ceptable vent lengths. Assign an equivalent feet value to

this elbow according to the larger size pipe being used.

Contact the Application Department for more information

concerning sizing of vent systems which include multiple

pipe sizes.

Use the following steps to correctly size vent pipe diameter.

Refer to Vent Pipe Size Determination Worksheet on

Page 48.

1 − Determine the vent termination and its corresponding

equivalent feet value according to table 3.

2 − Determine the number of 90° elbows required for both

indoor and outdoor (e.g. snow riser) use. Calculate the

corresponding equivalent feet of vent pipe.

3 − Determine the number of 45° elbows required for both

indoor and outdoor use. Calculate the corresponding

equivalent feet of vent pipe.

4 − Determine the length of straight pipe required.

5 − Add the total equivalent feet calculated in steps 1

through 4 and compare that length to the maximum

values given in table 5 for the proposed vent pipe di-

ameter. If the total equivalent length required exceeds

the maximum equivalent length listed in the appropri-

ate table, evaluate the next larger size pipe.

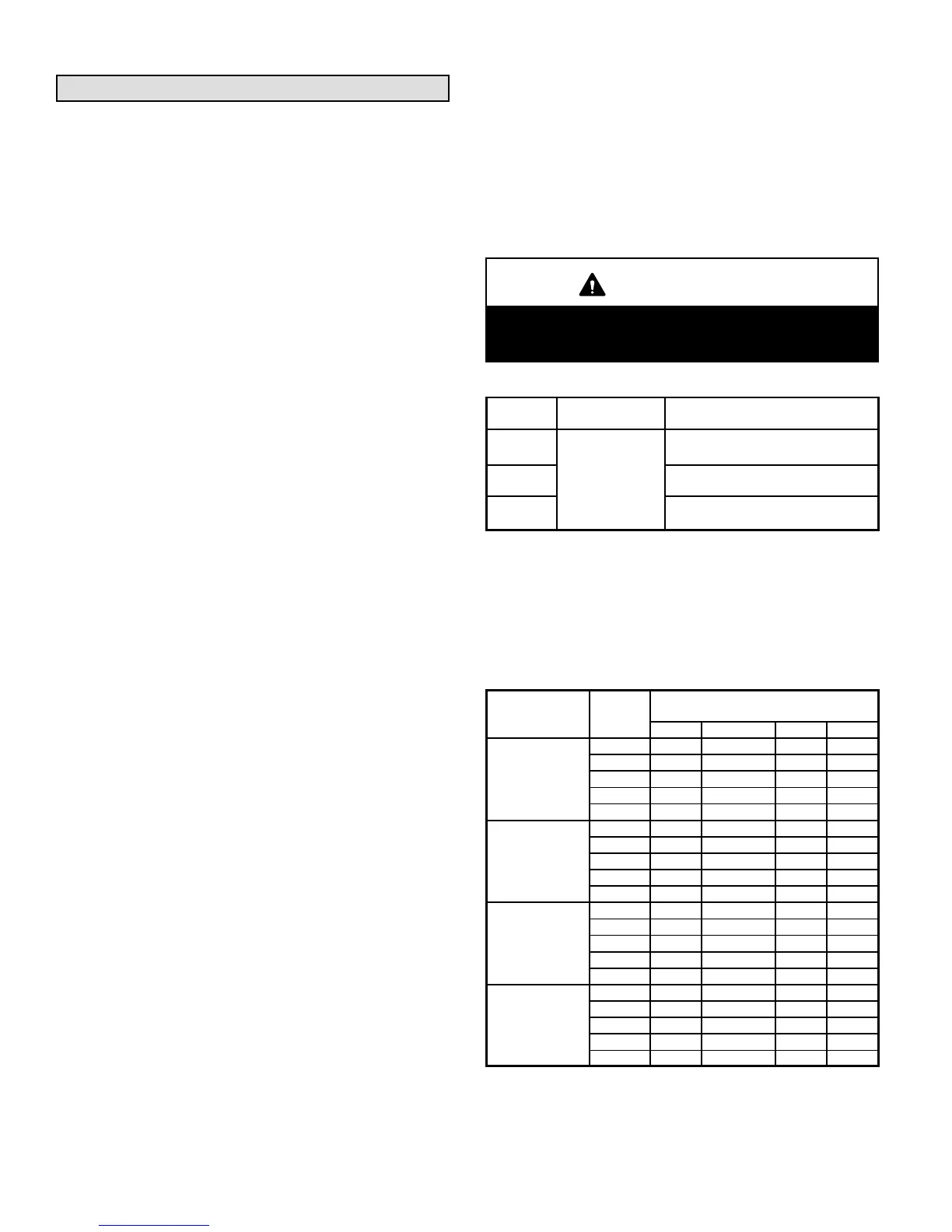

IMPORTANT

Do not use screens or perforated metal in exhaust

terminations. Doing so will cause freeze−ups and

may block the terminations.

TABLE 4

MINIMUM VENT PIPE LENGTHS

G43UF

MODEL

MIN. EQUIV.

VENT LENGTH

EXAMPLE

045, 070,

090

15 ft.*

5 ft. plus 2 elbows of 2", 2−1/2", 3"

or 4" diameter pipe

110**

5 ft. plus 2 elbows of 2", 2−1/2", 3" or

4" diameter pipe

135***

5 ft. plus 2 elbows of 3" or 4"

diameter pipe

*Any approved termination may be added to the minimum equivalent length

listed.

**G43UF−48C−110, G43UF−110H and G43UF−60C−110 must have 90° street

ell (supplied or field replacement Canadian kit) installed directly into unit flue

collar.

***G43UF−60D−135 must have 3" to 2" reducing ell (supplied or field replace-

ment Canadian kit) installed directly into unit flue collar.

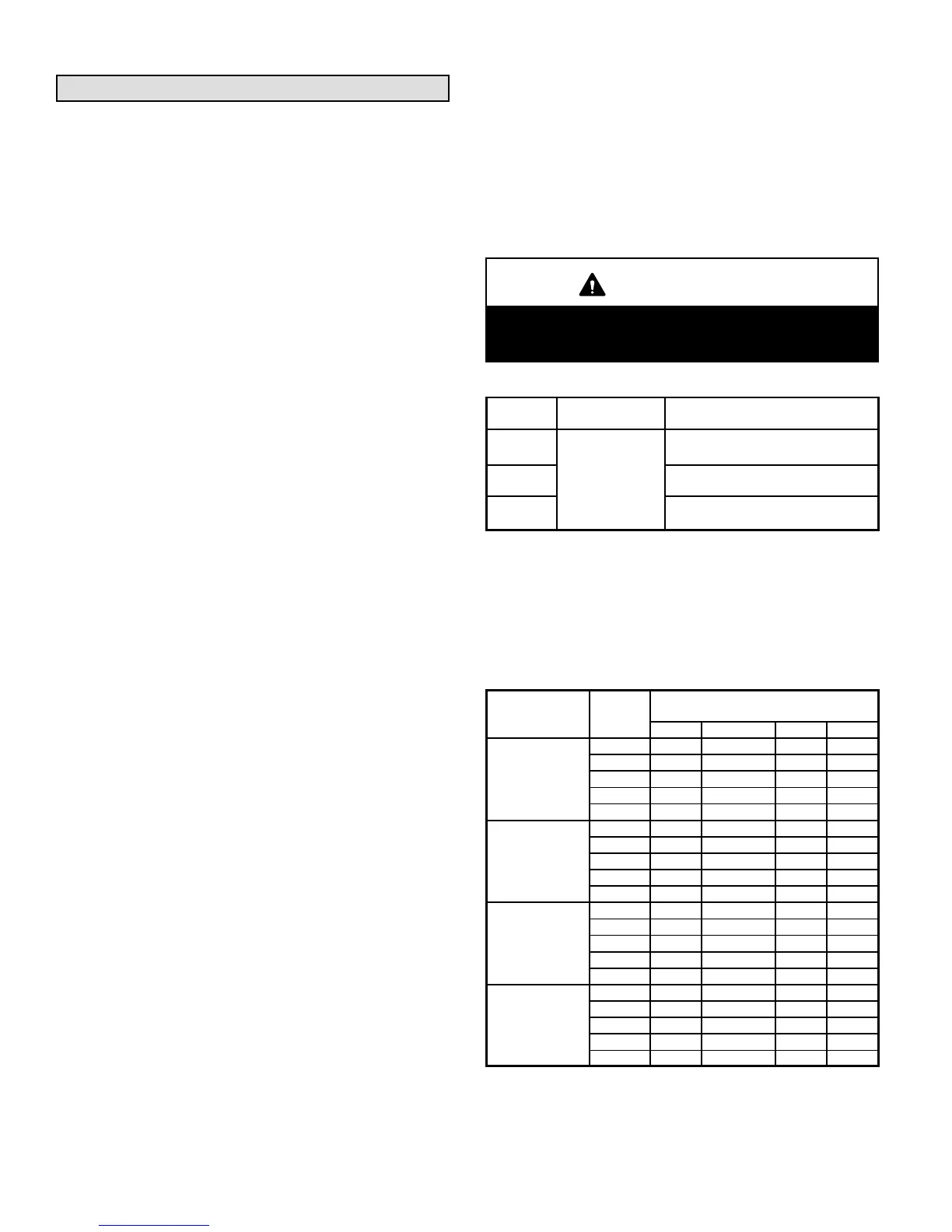

TABLE 5

MAXIMUM VENT PIPE LENGTHS

DIRECT (2 PIPE) AND NON−DIRECT (1 PIPE) APPLICATIONS

ALTITUDE

G43UF

MODEL

MAXIMUM EQUIVALENT VENT

LENGTH FEET

2" dia. 2−1/2" dia. 3" dia. 4" dia.

0 − 2000

(0 − 609 m)

045 110 135 160 250

070 70 135 160 250

090 50 100 125 225

110* 30 70 125 200

135** n/a n/a ***125 180

2001 − 4500

(610 − 1371 m)

045 110 135 160 250

070 70 135 160 250

090 50 100 125 225

110* 20 70 125 200

135** n/a n/a ***90 180

4501−7500

(1372−2286 m)

045 110 135 160 250

070 70 135 160 250

090 30 100 125 225

110* n/a 70 125 200

135** n/a n/a ***90 180

7501 − 10000

(2287 − 3048 m)

045 110 135 160 250

070 70 135 160 250

090 n/a 100 125 225

110* n/a 70 125 200

135** n/a n/a ***90 180

n/a −− Not allowed.

*G43UF−48C−110 and G43UF−60C−110 must have 90° street ell (supplied)

installed directly into unit flue collar.

**G43UF−60D−135 must have 3" to 2" reducing ell (supplied) installed directly

into unit flue collar.

***90° elbows used in configuration of G43UF−60D−135 vent, must be lim-

ited to 3" sweep elbows.

Loading...

Loading...