Page 35

Heating Sequence Of Operation

When thermostat calls for heat, combustion air inducer

starts.

Combustion air pressure switch proves blower opera-

tion. Switch is factory set and requires no adjustment.

After a 15−second prepurge, the hot surface ignitor en-

ergizes.

After a 20−second ignitor warm−up period, the gas

valve solenoid opens.

Gas is ignited, flame sensor proves the flame, and the

combustion process continues.

If flame is not detected after first ignition trial, the igni-

tion control will repeat steps 3 and 4 four more times

before locking out the gas valve (WATCHGUARD"

flame failure mode). The ignition control will then auto-

matically repeat steps 1 through 6 after 60 minutes.

To interrupt the 60−minute WATCHGUARD" period,

move thermostat from Heat" to OFF" then back to

Heat". Heating sequence then restarts at step 1.

Gas Pressure Adjustment

Gas Flow (Approximate)

1 − Operate unit at least 15 minutes before checking gas

flow. Determine the time in seconds for one revolu-

tions of gas through the meter. A portable LP gas me-

ter (17Y44) is available for LP applications.

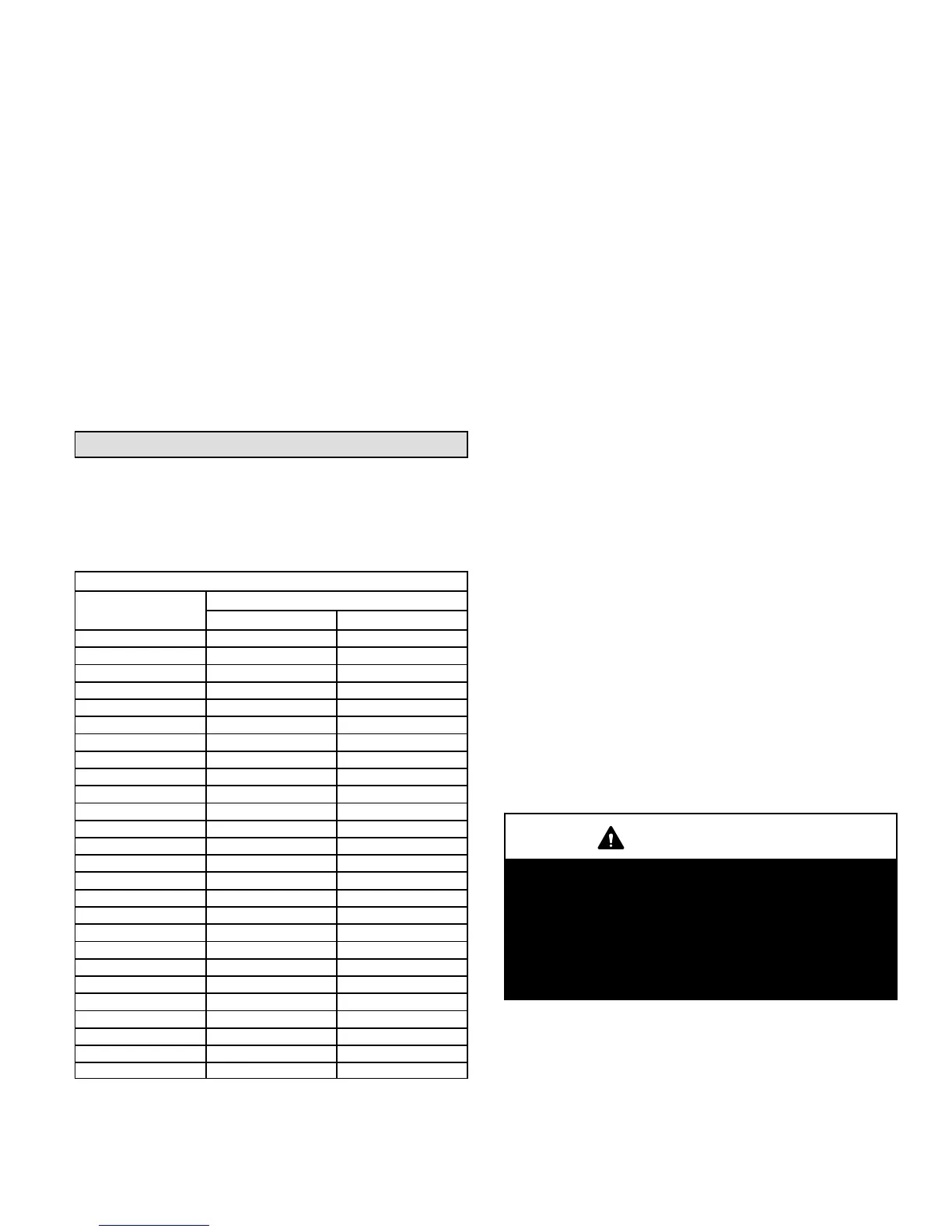

TABLE 8

Gas Flow Rate (Ft.

3

/Hr.)

Seconds for 1

Revolution

Gas Meter Size

1/2 cu ft Dial 1 cu ft Dial

10 180 360

12 150 300

14 129 257

16 113 225

18 100 200

20 90 180

22 82 164

24 75 150

26 69 138

28 64 129

30 60 120

32 56 113

34 53 106

36 50 100

38 47 95

40 45 90

42 43 86

44 41 82

46 39 78

48 38 75

50 36 72

52 35 69

54 33 67

56 32 64

58 31 62

60 30 60

2 − Compare the number of seconds and the gas meter

size in table 8 to determine the gas flow rate. Multiply

the gas flow rate by the heating value to determine the

unit input rate. If manifold pressure is correct and the

unit input rate is incorrect, check gas orifices for proper

size and restriction.

3 − Remove temporary gas meter if installed.

NOTE − To obtain accurate reading, shut off all other gas

appliances connected to meter.

Gas Supply Pressure Measurement

A threaded plug on the inlet side of the gas valve provides

access to the supply pressure tap. Remove the threaded

plug, install a field−provided barbed fitting and connect a

manometer to measure supply pressure. Replace the

threaded plug after measurements have been taken.

Manifold Pressure Measurement

To correctly measure manifold pressure, the differential

pressure between the positive gas manifold and the nega-

tive burner box must be considered. Use pressure test

adapter kit (available as Lennox part 10L34) to assist in

measurement.

1 − Remove the threaded plug from the outlet side of the

gas valve and install a field−provided barbed fitting.

Connect test gauge +" connection to barbed fitting to

measure manifold pressure.

2 − Tee into the gas valve regulator vent hose and connect

test gauge −" connection.

3 − Start unit and allow 5 minutes for unit to reach steady

state.

4 − While waiting for the unit to stabilize, notice the flame.

Flame should be stable and should not lift from burner.

Natural gas should burn blue.

5 − After allowing unit to stabilize for 5 minutes, record

manifold pressure and compare to value given in table

9.

NOTE − Shut unit off and remove manometer as soon as an

accurate reading has been obtained. Take care to remove

barbed fitting and replace threaded plug.

IMPORTANT

The White Rodgers 36G gas valve (figure 45) is

equipped with pressure posts for measuring supply

and manifold pressures. The posts provide built−in

hose connections and have an integral 3/32" Allen−

head screw. Rotate the screw counterclockwise one

full turn to permit pressure measurement. Reseat the

screw (rotate one full turn clockwise) after measure-

ments have been taken to prevent gas leakage.

Loading...

Loading...