Page 11

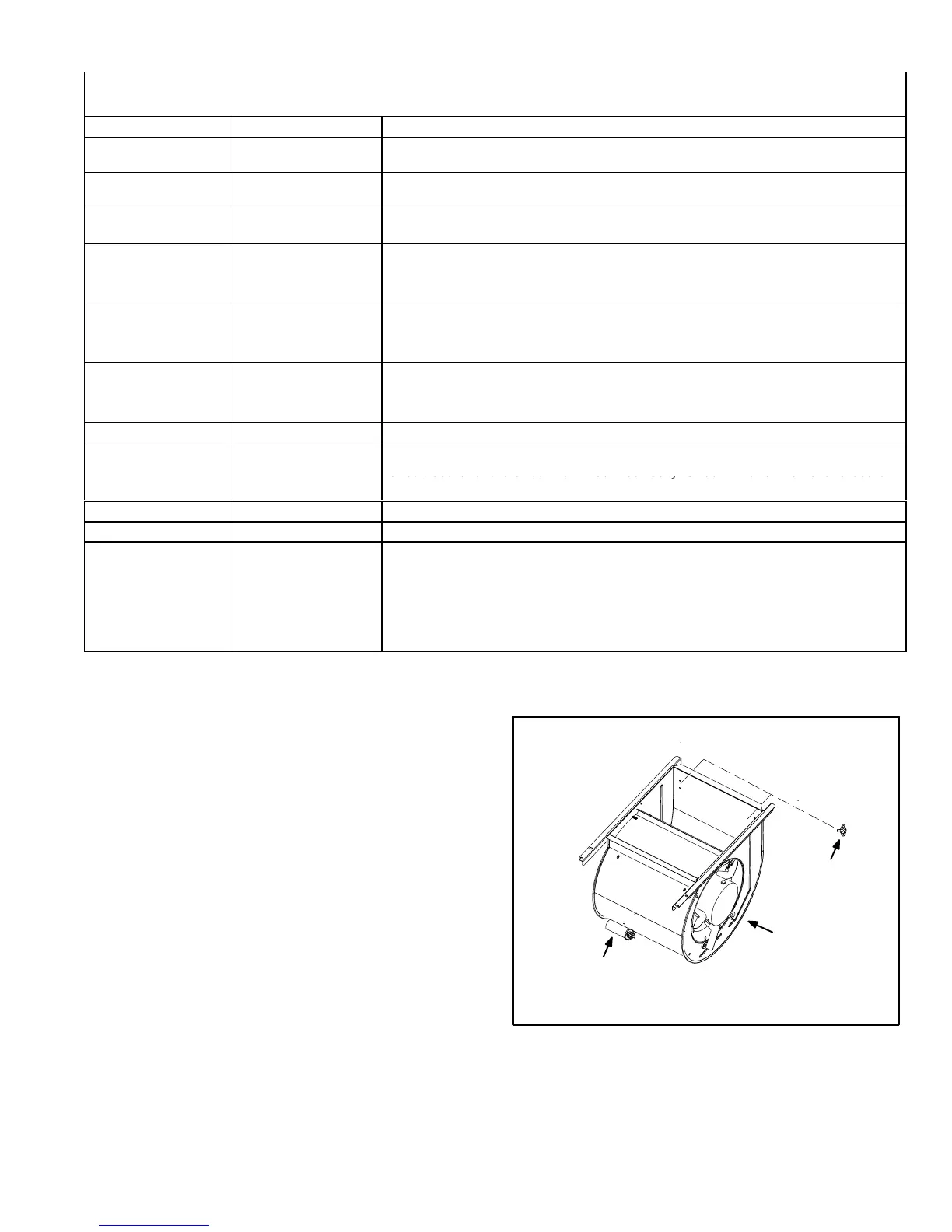

TABLE 6

DIAGNOSTIC CODES

Diagnostic LEDs are labeled DS1 and DS2. See figure 4 for location of diagnostic LEDs.

DS1 DS2 DESCRIPTION

SIMULTANEOUS

SLOW FLASH

SIMULTANEOUS

SLOW FLASH

Power on − Normal operation.

Also signaled during cooling and continuous fan.

SIMULTANEOUS

FAST FLASH

SIMULTANEOUS

FAST FLASH

Normal operation − signaled when heating demand initiated at thermostat.

SLOW FLASH ON

Primary, secondary, backup secondary or rollout limit switch open. Limits must

close within 3 minutes or unit goes into 1 hour Watchguard.

OFF SLOW FLASH

Low prove switch open;

OR: Blocked inlet/exhaust vent;

OR: Low prove switch closed prior to activation of combustion air inducer.

OFF FAST FLASH

High prove switch open;

OR: Blocked inlet/exhaust vent;

OR: High prove switch closed prior to activation of combustion air inducer.

ALTERNATING

SLOW FLASH

ALTERNATING

SLOW FLASH

Watchguard −− burners failed to ignite; OR limit open more than 3 minutes;

OR lost flame sense 5 times in one heating cycle;

OR pressure switch opened 5 times in one heating cycle.

SLOW FLASH OFF Flame sensed without gas valve energized.

ON ON

ON

OFF

Circuit board failure or control wired incorrectly. Check 24 and 115 volts to board.

OFF ON

FAST FLASH SLOW FLASH Main power polarity reversed. Switch line and neutral.

SLOW FLASH FAST FLASH Low flame signal. Measures below 0.23 microAmps. Replace flame sense rod.

ALTERNATING

FAST FLASH

ALTERNATING

FAST FLASH

The following conditions are sensed during the ignitor warm−up period only:

1) Improper main ground;

2) Broken ignitor; OR: Open ignitor circuit;

3) Line voltage below 75 volts.

(If voltage lower than 75 volts prior to ignitor warm-up, control will signal waiting on

call from thermostat, and will not respond.

NOTE − Slow flash rate equals 1 Hz (one flash per second). Fast flash rate equals 3 Hz (three flashes per second).

Low flame sense current = 0.17−0.22 microAmps.

B−Blower Compartment

1. Blower Motor (B3) and Capacitor (C4)

All G61MP units use direct drive blower motors. All motors

are 120V permanent split capacitor motors to ensure maxi-

mum efficiency. Ratings for capacitors will be on motor

nameplate. See SPECIFICATIONS section for motor speci-

fications.

NOTE − Shafts on 1 HP motors have 2 flat sides and are

matched with blower wheels with 2 set screws.

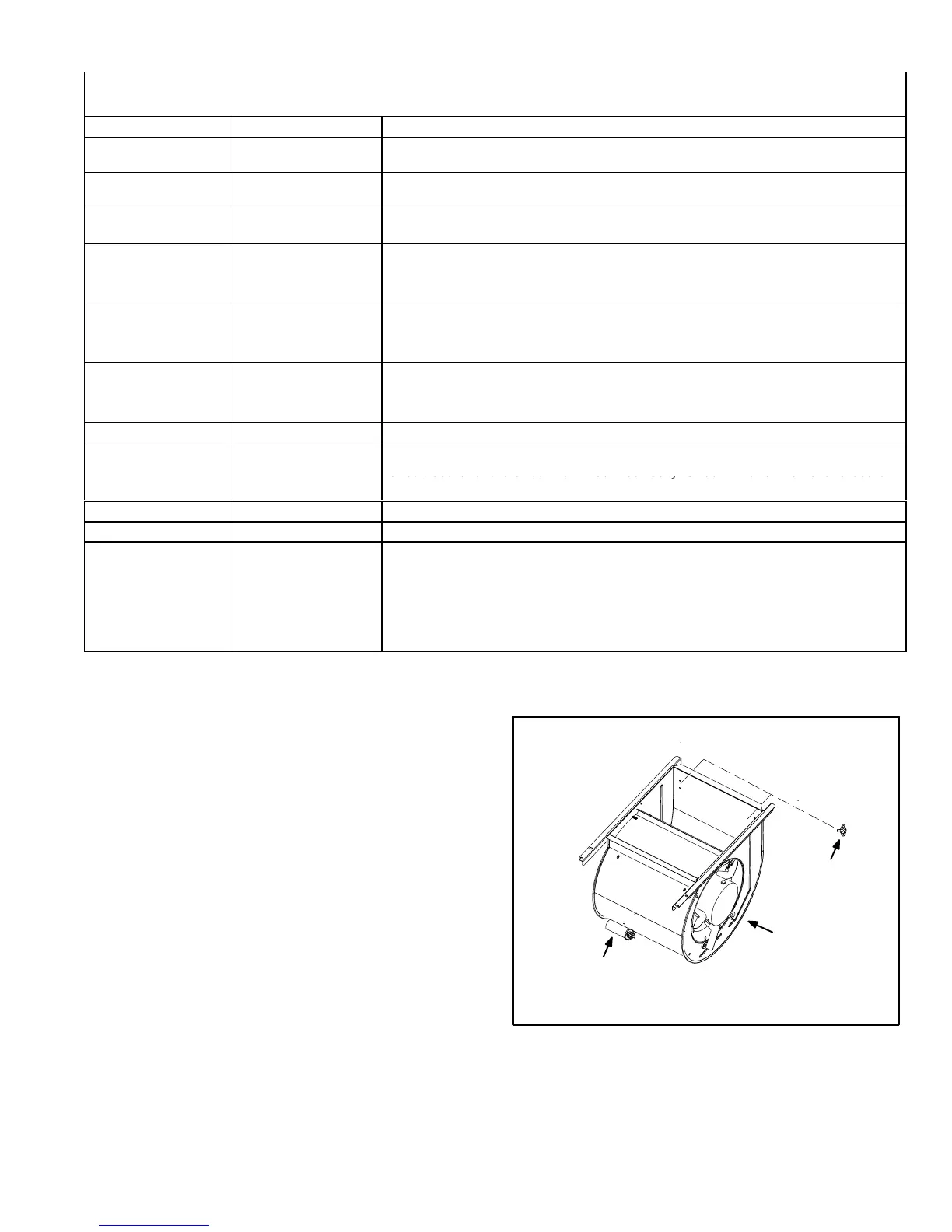

2. Secondary Limit Controls (S21)

The secondary limits (S21) on G61MP units are located in the

blower compartment on the back side of the blower housing.

See figure 5. All G61MP units are equipped with two secon-

dary limts. When excess heat is sensed in the blower compart-

ment, the limit will open. If the limit is open, the furnace control

energizes the supply air blower and closes the gas valve. The

limit automatically resets when unit temperature returns to nor-

mal. The switch is factory set to open at 125°F and cannot be

adjusted.

FIGURE 5

SUPPLY AIR BLOWER

AND SECONDARY LIMITS

SECONDARY

LIMIT (S)

CAPACITOR

MOTOR/BLOWER

ASSEMBLY

To Remove Blower From Unit: Disconnect Power, Remove Control

Box, Remove Bolts and Unplug Motor Wires From Control Board.

Then Slide Out Front of Unit.

Loading...

Loading...