Page 22

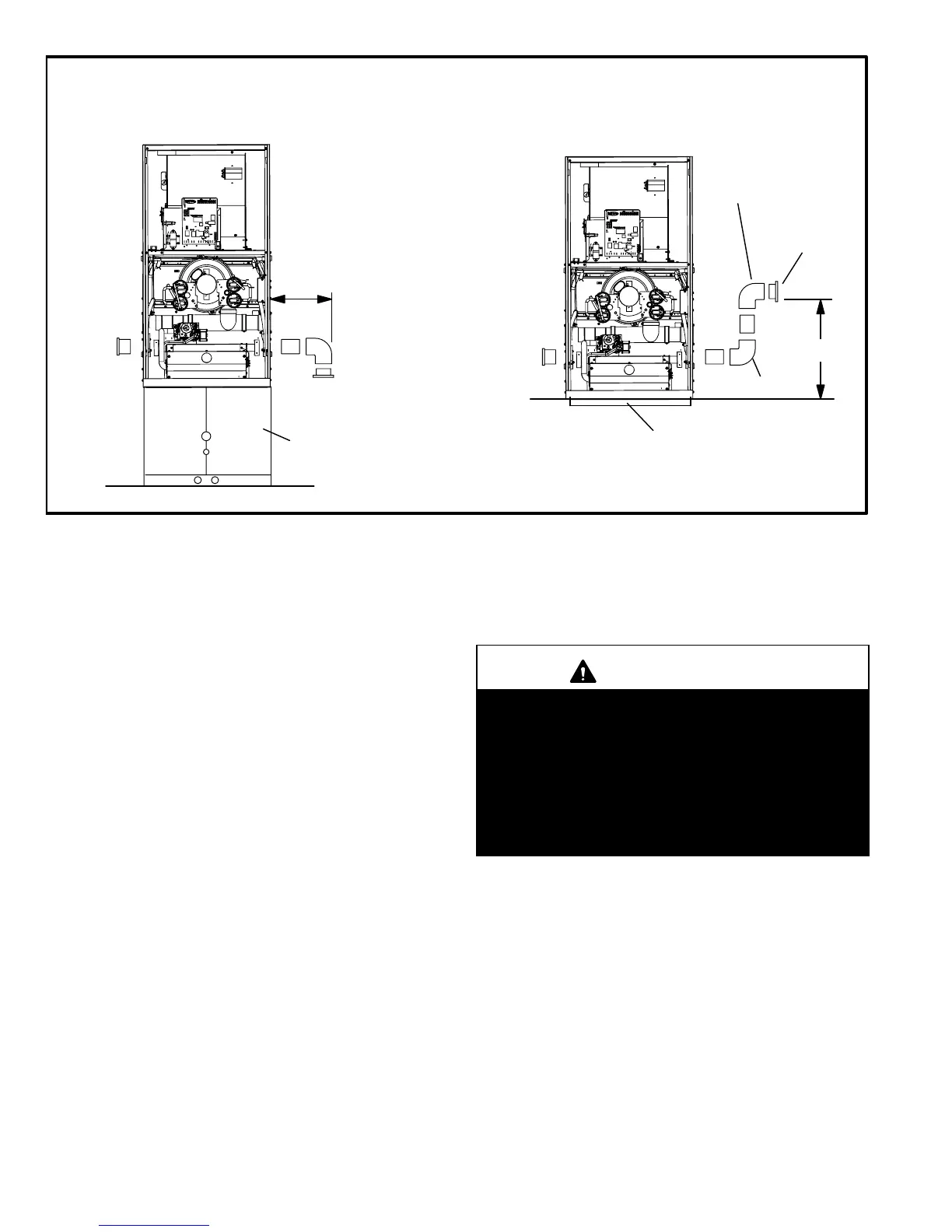

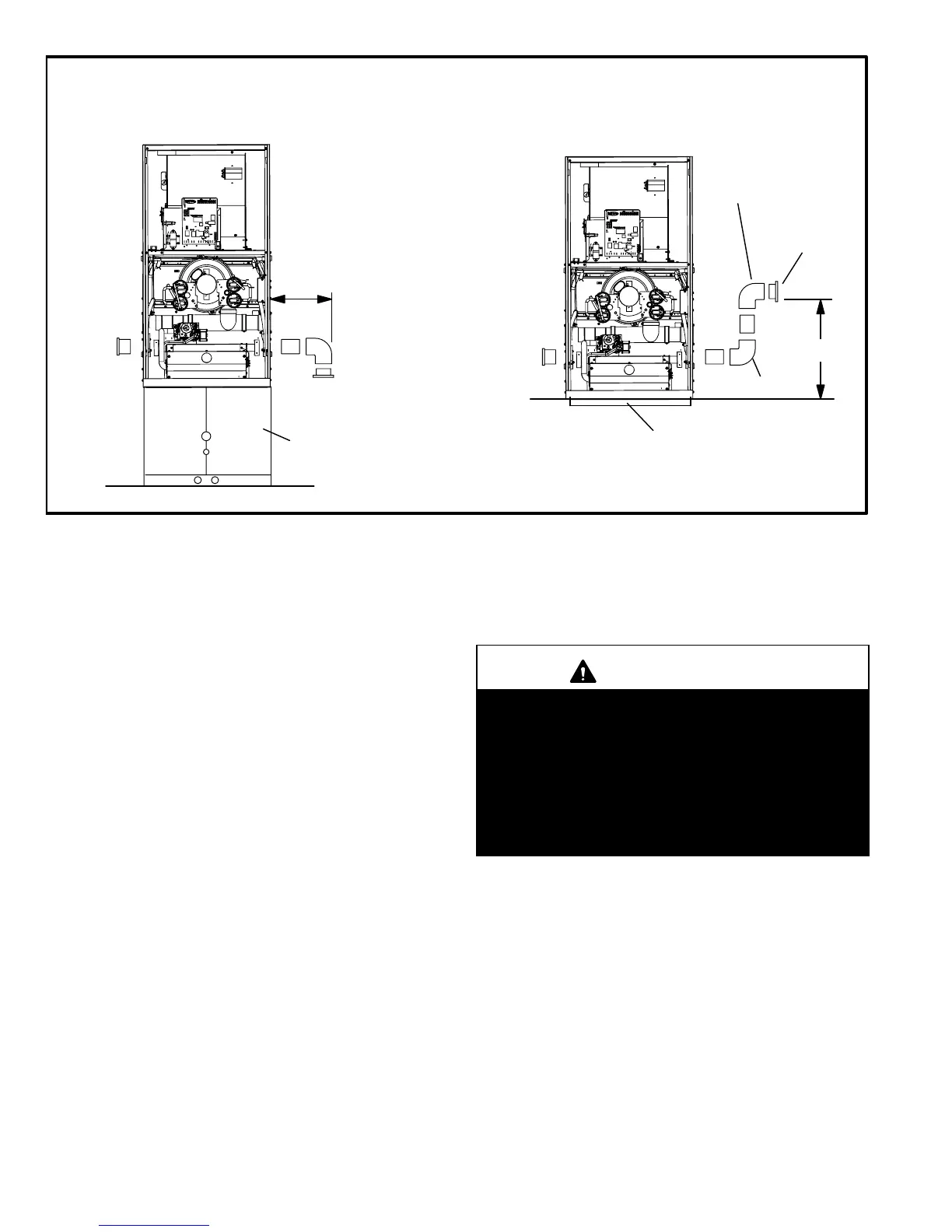

TYPICAL AIR INTAKE PIPE CONNECTIONS

DOWNFLOW NON-DIRECT VENT APPLICATIONS

(Right-Hand Exit in Downflow Applications Shown)

FIGURE 18

PLUG

(Must be

glued in

place)

6 in. Max.

PLUG

(Must be

glued in

place)

Downflow Additive Flloor Base

18 in.

Downflow

Evaporator

Coil

2"

2" SWEEP

ELL

2" SWEEP ELL

INTAKE DEBRIS

SCREEN

(Provided)

INTAKE

DEBRIS

SCREEN

(Provided)

NOTE − Debris screen and sweep ell may be rotated, so that

screen may be positioned to face forward, backward or to the side.

1 − Use field−provided materials and the factory−provided

air intake screen to route the intake piping as shown in

figures 17 and 18. Maintain a minimum clearance of 3"

(76mm) around the air intake opening. The air intake

opening (with the protective screen) should always be

directed either downward or straight out. Use 2" pipe

and fittings only and make sure that the air intake does

not extend more than 6" beyond the G61MP cabinet.

The air intake connector must not be located near

the floor. To avoid this complication in downflow

applications which do not include a downflow

evaporator coil, the intake air routing should be modi-

fied as shown in figure 18.

2 − Use a #7 sheet metal screw to secure the intake pipe to

the connector, if desired. A pilot indentation is provided in

the slip connector to assist in locating and starting the fas-

tener.

3 − Glue the provided 2" plug into the unused air intake con-

nector on the opposite side of the cabinet.

Testing for Proper Venting and Sufficient Combustion Air

(Non−Direct Vent Applications Only)

WARNING

CARBON MONOXIDE POISONING HAZARD!

Failure to follow the steps outlined below for each

appliance connected to the venting system being

placed into operation could result in carbon monox-

ide poisoning or death.

The following steps shall be followed for each ap-

pliance connected to the venting system being

placed into operation, while all other appliances con-

nected to the venting system are not in operation.

After the G61MP gas furnace has been started, the follow-

ing test should be conducted to ensure proper venting and

sufficient combustion air has been provided to the G61MP,

as well as to other gas-fired appliances which are separate-

ly vented. The test should be conducted while all ap-

pliances (both in operation and those not in operation) are

connected to the venting system being tested. If the vent-

ing system has been installed improperly, or if provisions

have not been made for sufficient amounts of combustion

air, corrections must be made as outlined in the previous

section.

1 − Seal any unused openings in the venting system.

2 − Visually inspect the venting system for proper size and

horizontal pitch. Determine there is no blockage or re-

striction, leakage, corrosion, or other deficiencies

which could cause an unsafe condition.

Loading...

Loading...