11

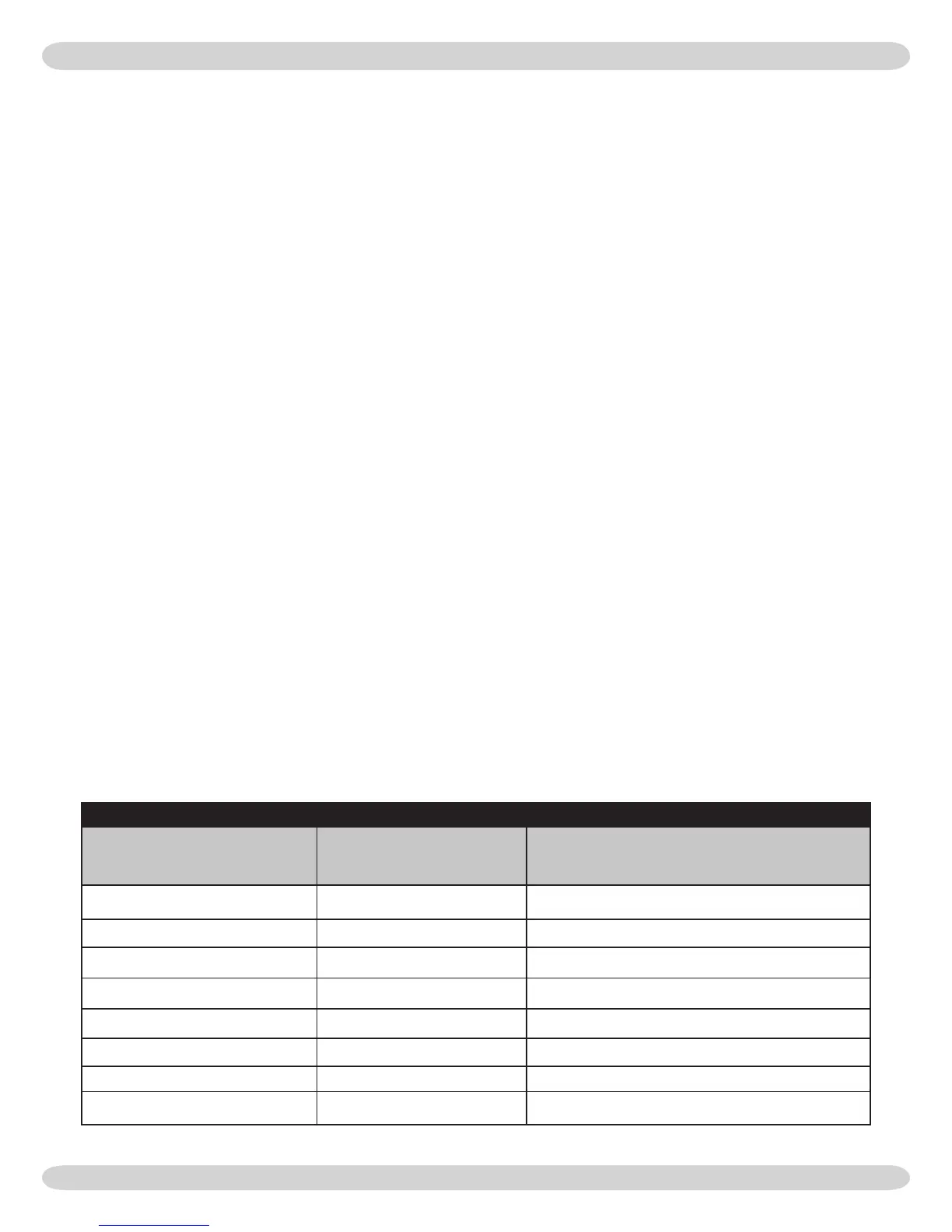

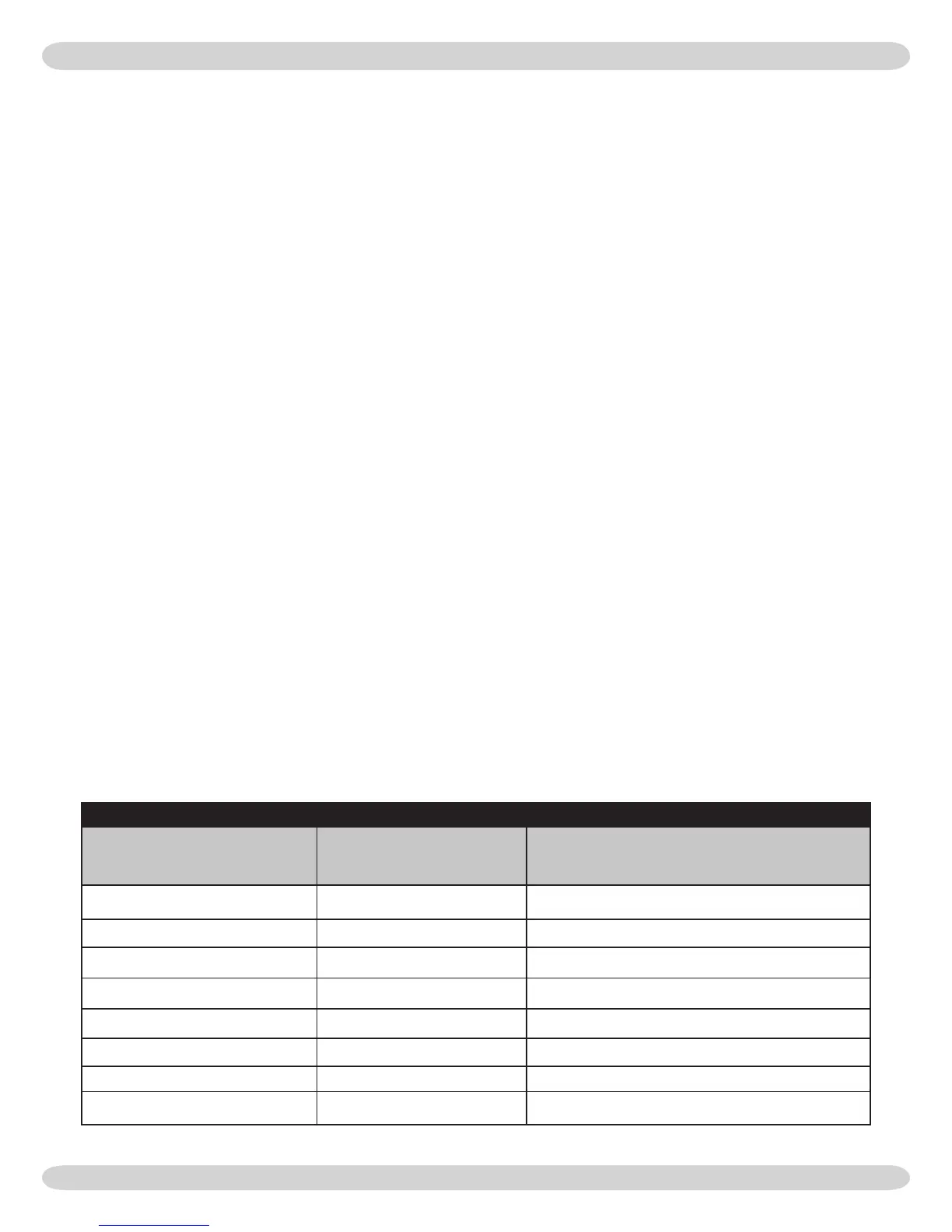

TABLE #2 -

BOILER CLEARANCES

Unit

Combustible Clearance

Inch (mm)

Accessibility, Cleaning, and Servicing

Inch (mm)

Top 1 (25.4) 8 (203.2)

Left Side 1 (25.4) 24 (609.6)

Right Side 8 (203.2) -

Base 1 (25.4) -

Front 0 (0) 24 (609.6)

Back 1 (25.4) -

Intake/Vent Piping 0 (0) -

Near Boiler Hot Water Piping 1 (25.4) -

All distances measured from the cabinet of the boiler.

Select a location which is level, central to the piping sys-

7.

tems served and as close to the vent and air intake termi-

nals as possible.

Accessibility clearances, if more stringent (i.e. larger clear-

8.

ances) than required re protection clearances, must be

used for the boiler installation. Accessibility clearances

may be achieved with the use of removable walls or parti-

tions.

e boiler is approved for installation in closets and on

9.

combustible oors. is boiler shall NOT be installed on

carpeting.

e clearances shown in Table #2 indicate required clear-

10.

ances per IAS listing. A minimum 1” clearance must be

maintained between combustible construction and each

of the le, top and back surfaces of the boiler. A minimum

8” clearance is required on the right side, to allow room

for the inlet air pipe. An 18” clearance must be maintained

at a side where passage is required to access another side

for cleaning or servicing, inspection or replacement of

any parts that normally may require such attention. Allow

at least 24” at the front and le side and 8” at the top for

servicing. No clearances are required to venting or com-

bustion air intake piping.

Equipment shall be installed in a location which facilitates

11.

the operation of venting and combustion air intake piping

systems as described in this manual.

Advise owner of boiler to keep venting and combustion

12.

air intake passages free of obstructions. both the venting

and combustion air intake piping systems connected to

the outdoors must permit ow through the piping systems

without restrictions for the boiler to operate.

e boiler shall be installed such that the automatic gas ig-

13.

nition system components are protected from water (drip-

ping, spraying, rain, etc.) during operation and service

(circulator replacement, control replacement, etc.).

is boiler requires a dedicated direct vent system. In a direct

vent system, all air for combustion is taken directly from

outside atmosphere, and all ue products are discharged to

outside atmosphere.

Combustion air and vent pipe connections must terminate to-

gether in the same atmospheric pressure zone, either through

the roof or sidewall (roof termination preferred). See

Figures

#9 & #10

(in Combustion Air And Vent Pipe section near

center of this manual) for required clearances.

Loading...

Loading...