29

Never use a match or open ame to test for leaks.

Refer to Figure #12 (on following page) for the general lay-

out at the boiler. It shows the basic ttings you will need. e

gas line enters the boiler from the right side jacket panel. e

boiler may receive the gas supply pipe through the le side, or

rear jacket panel by relocating the gas valve connector and pipe

assembly. e boiler is equipped with a ½” NPT connection on

the gas valve for supply piping. e following rules apply:

1. Use only those piping materials and joining methods

1.

listed as acceptable by the authority having jurisdiction, or

in the absence of such requirements, by the National Fuel

Gas Code, ANSI Z223.1- latest revision. In Canada, follow

the CSA- B 149.1 and .2 Installation Codes for Gas Burn-

ing Appliances and Equipment.

2. Use pipe joint compound suitable for liqueed petro-

2.

leum gas on male threads only.

3. Use ground joint unions.

3.

4. Install a sediment trap upstream of gas controls.

4.

5. Use two pipe wrenches when making the connection to

5.

the gas valve to keep it from turning.

6. Install a manual shuto valve in the vertical pipe about 5

6.

feet above oor.

7. Tighten all joints securely.

7.

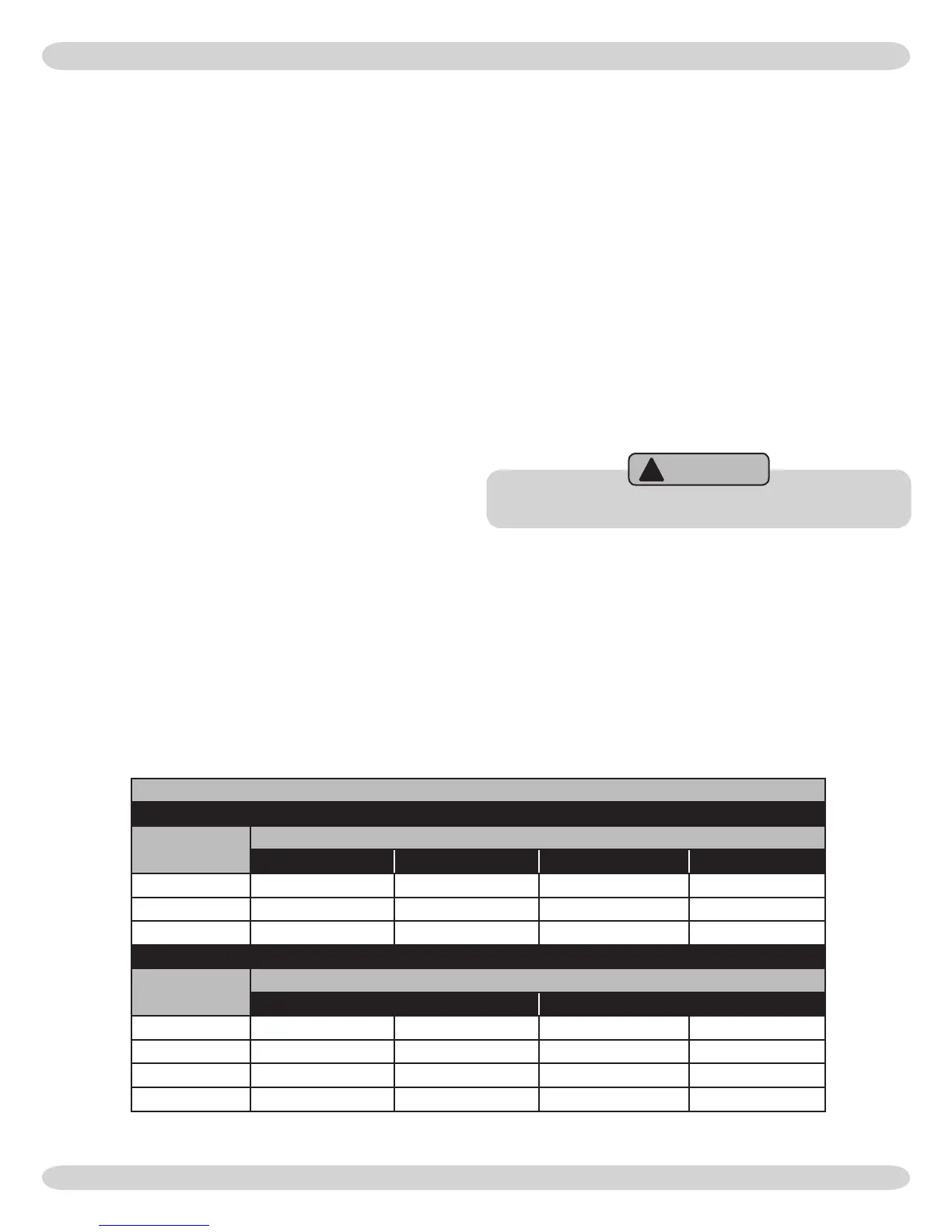

TABlE #3 – GAS PIPE SIzES

NATURAL GAS

Length of

Pipe - Ft.

Pipe Capacity - BTU Per Hour Input Includes Fittings

1/2” 3/4” 1” 1 1/4”

20 92,000 190,000 350,000 625,000

40 63,000 130,000 245,000 445,000

60 50,000 105,000 195,000 365,000

PROPANE GAS

Length of

Pipe - Ft.

Pipe Capacity - BTU Per Hour Input Includes Fittings

Copper Tubing* Iron Pipe

5/8” 3/4” 1/2” 3/4”

20 131,000 216,000 189,000 393,000

40 90,000 145,000 129,000 267,000

60 72,000 121,000 103,000 217,000

* Outside diameter

8. Propane gas connections should only be made by a

8.

licensed propane installer.

9. Two stage regulation should be used by the propane

9.

installer.

10. Propane gas piping should be checked out by the

10.

propane installer.

Aer all connection have been made, check immediately

for leaks. Open the manual shuto valve. Test for leaks by

applying soap suds (or a liquid detergent) to each joint.

Bubbles forming indicate leak. CORRECT EVEN THE

SMALLEST LEAK AT ONCE.

WARNING

!

Loading...

Loading...