8

Staged Heat Pump Units

Should the pressure switch open during heat pump heating second stage

operation:

• Lennox communicating thermostat will downstage the heat pump from

second-stage to rst-stage heating operation in order to bring the system

pressure down to a point where the switch closes again.

• If the unit is already running in rst-stage when the pressure switch opens,

the unit will shut off.

• If the switch closes within 60 seconds, then the Lennox communicating series

thermostat may send a demand for second-stage heat pump if needed.

• If the switch does not close within 60 seconds, the Lennox communicating

thermostat stops heat pump heating and satises the heating demand with

backup heat (backup heat is either electric or gas) regardless of the ambient

temperature being above the high balance point.

The heat pump is used again on the next call provided the pressure switch has

closed; otherwise backup heat is used on subsequent heating calls until the

pressure switch closes.

Variable Capacity Heat Pump Units (XP20 and XP25)

If the pressure switch opens during heat pump heating operation:

• Lennox communicating series thermostat will respond by sending a HP heat

demand with the demanded rate equal to the current rate 25%. (i.e. the

switch opens during a 90% heating demand,

• Lennox communicating thermostat then sends a demand for 90 25 = 65%)

If new calculated rate is below the minimum for the unit, minimum demand

is sent.

• If the switch closes within 60 seconds, then the Lennox communicating

series thermostat may change the demand for the heat pump as determined

by the DATS.

• If the switch does not close within 60 seconds, the Lennox communicating

series thermostat stops heat pump heating and satises the heating demand

with backup heat (backup heat is either electric or gas) regardless of the

ambient temperature being above the hi balance point.

The heat pump is used again on the next call provided the pressure switch has

closed; otherwise backup heat is used on subsequent heating calls until the

pressure switch closes.

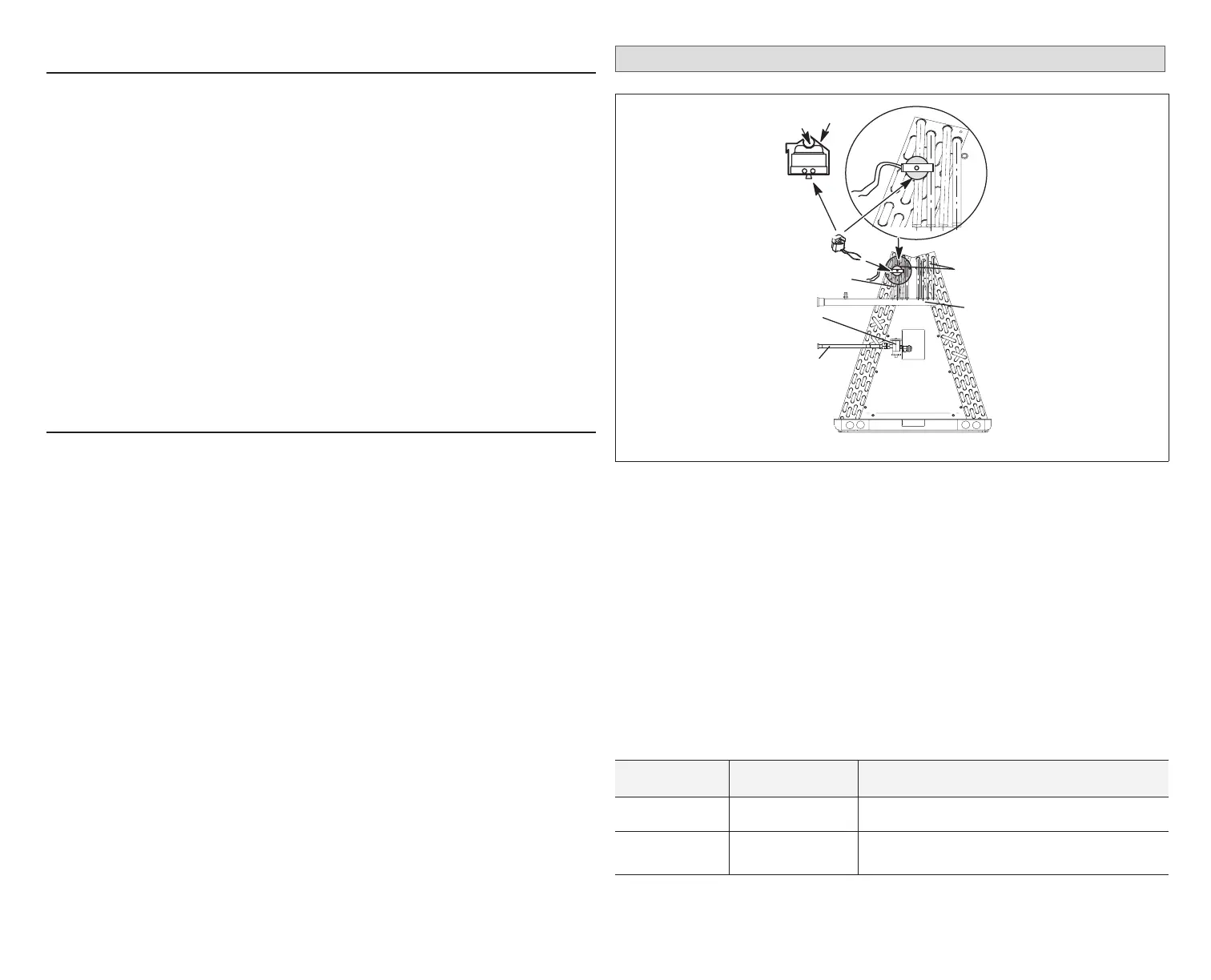

Freezestat (Optional)

CLIP

COPPER

LINE

EXPANSION

VALVE

FREEZESTAT

SUCTION

MANIFOLD

LIQUID LINE

LAST HAIRPINS

COPPER LINES

Figure 6. Typical Freezestat Installation - Indoor Coil

This optional component is only required if there is a small zone with little

airow which is causing the indoor coil to freeze up. However, normal return air

temperature should prevent this from occurring. The addition of the freezestat

will provide for added protection.

NOTE: The damper control module comes from the factory with a insertion

bridge installed on the freezestat terminals (see “Figure 7. Damper

Control Jumpers LEDs and Connections” on page 14). Do not

remove unless a freezestat is connected. Outdoor unit will not operate

if insertion bridge is removed (missing) and no freezestat is installed.

The table following lists available freezestats for use with the damper control

module.

Table 7. Available Freezestats

Catalog Number Piping Size Description

93G35 ⅜” Opens at 29°F, and closes at 58°F

50A93 ⅝” Opens at 36°F, and closes at 58°F

Suggested Freezestat Installation Method

The following is the recommended method for installation of the freezestat for

Loading...

Loading...