Installation

4-17

BA9300SU EN 2.1

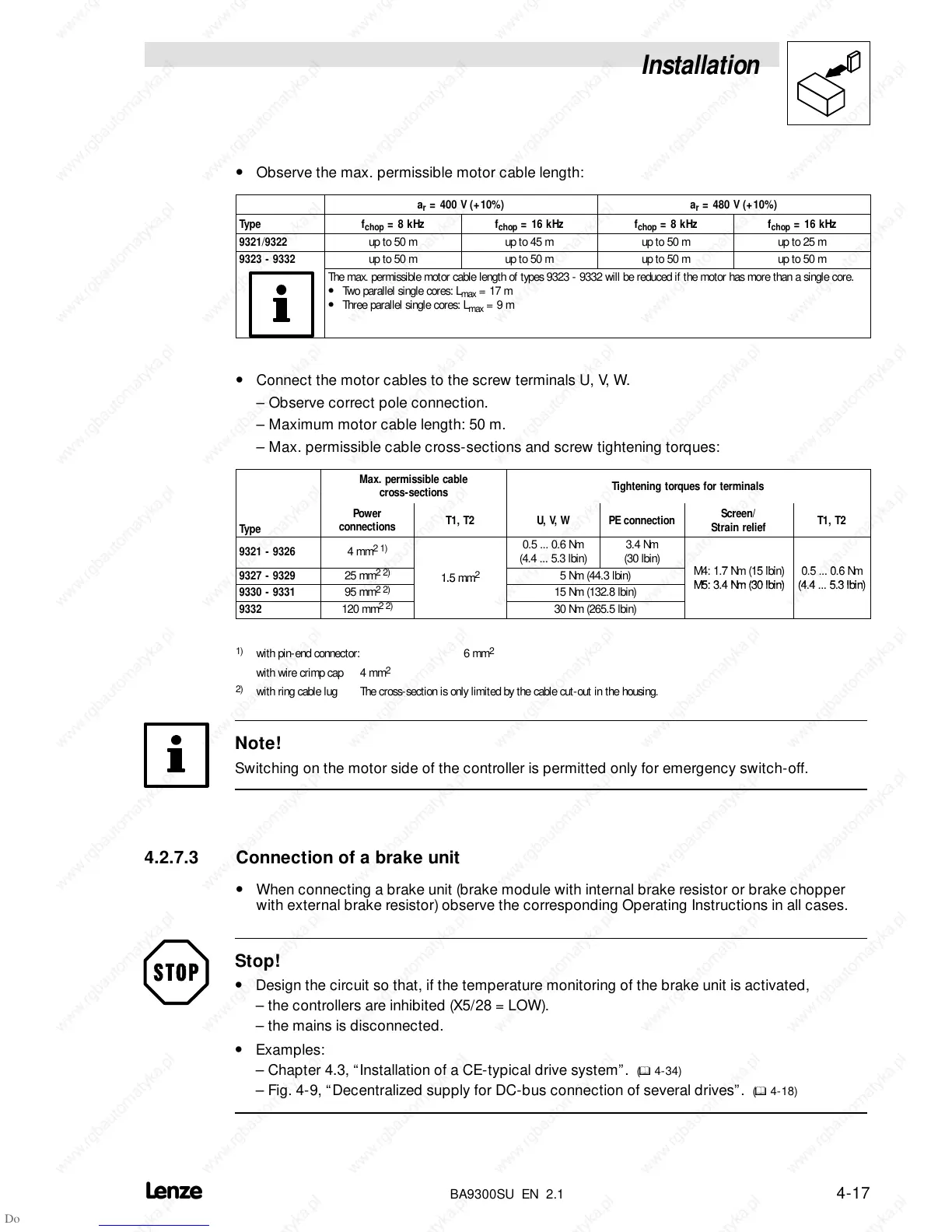

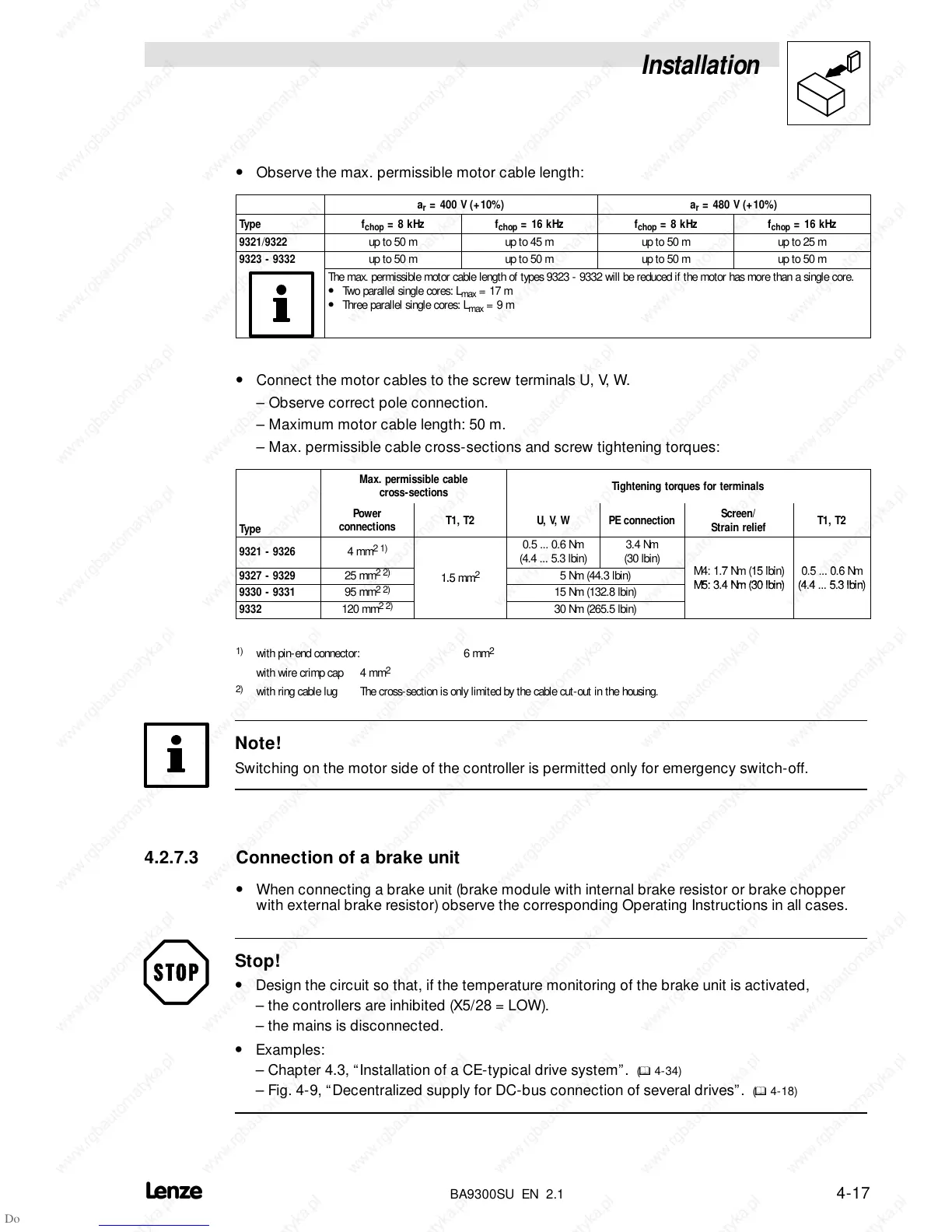

• Observe the max. permissible motor cable length:

a

r

= 400 V (+10%) a

r

= 480 V (+10%)

Type f

chop

=8kHz f

chop

=16kHz f

chop

=8kHz f

chop

=16kHz

9321/9322 up to 50 m up to 45 m up to 50 m up to 25 m

9323 - 9332 up to 50 m up to 50 m up to 50 m up to 50 m

The max. permissible motor cable length of types 9323 - 9332 will be reduced if the motor has more than a single core.

• Two parallel single cores: L

max

=17m

• Three parallel single cores: L

max

=9m

• Connect the motor cables to the screw terminals U, V, W.

– Observe correct pole connection.

– Maximum motor cable length: 50 m.

– Max. permissible cable cross-sections and screw tightening torques:

Max. permissible cable

cross-sections

Tightening torques for terminals

Type

Power

connections

T1, T2 U, V, W PE connection

Screen/

Strain relief

T1, T2

9321 - 9326 4mm

21)

0.5 ... 0.6 Nm

(4.4 ... 5.3 lbin)

3.4 Nm

(30 lbin)

9332 120 mm

22)

30 Nm (265.5 lbin)

1)

with pin-end connector: 6 mm

2

with wire crimp cap 4 mm

2

2)

with ring cable lug The cross-section is only limited by the cable cut-out in the housing.

Note!

Switching on the motor side of the controller is permitted only for emergency switch-off.

4.2.7.3 Connection of a brake unit

• When connecting a brake unit (brake module with internal brake resistor or brake chopper

with external brake resistor) observe the corresponding Operating Instructions in all cases.

Stop!

• Design the circuit so that, if the temperature monitoring of the brake unit is activated,

– the controllers are inhibited (X5/28 = LOW).

– the mains is disconnected.

• Examples:

– Chapter 4.3, “Installation of a CE-typical drive system”.

(

^

4-34)

– Fig. 4-9, “Decentralized supply for DC-bus connection of several drives”. (

^

4-18)

Loading...

Loading...