Mechanical installation

Preparation

4

21

Lenze ¯ MA 12.0014 ¯ 5.1

4.3 Preparation

¯ Protect shaft sealing rings against contact with solvents!

¯ Thoroughly remove anticorrosion agents from the output shaft and from flange

faces.

¯ Repair paintwork damage.

¯ In some cases, due to lack of space, stud bolts with nuts must be used instead of

head screws. In these cases, contact Lenze, if necessary.

Tighten all screw connections with the torques given and lock them with standard

screw locking adhesive!

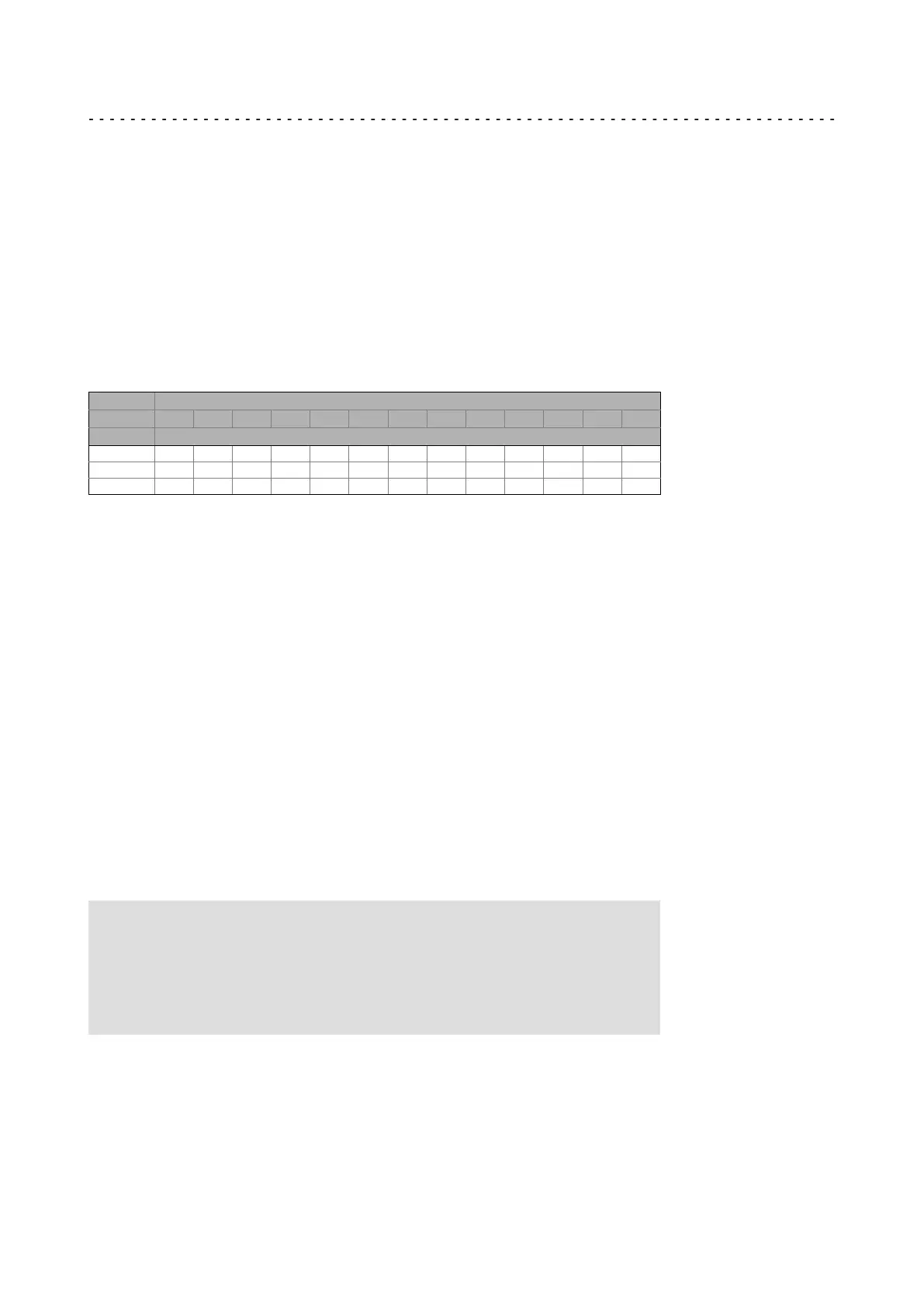

Thread

M3 M4 M5 M6 M8 M10 M12 M16 M20 M24 M27 M30 M36

Strength Tightening torque [Nm]

4.8 0.7 1.4 2.8 4.8 12 23 − − − − − − −

8.8 1.3 3.0 5.9 10.1 24.6 48 84 206 415 714 1050 1428 2482

10.9 1.9 4.6 8.6 14.9 36.1 71 123 302 592 1017 1496 2033 3535

Tab. 2 Tightening torques for friction factor m = 0.12; tolerance of the tightening torque ±10 %

Please note: increase the tightening torque by 10% for screwed connections with flat

gaskets.

Correcting the lubricant amount

If the oil quantity in the gearbox has been increased for longtime storage ((¶ 10)), the

oil must be drained completely and then must be refilled for the mounting position

provided. The following steps must be complied with:

1. Place receptacle under oil drain plug.

2. Remove breathing / oil filler plug.

3. Completely drain lubricant.

4. Screw in oil drain plug.

5. Fill in amount of oil for the mounting position provided (according to nameplate).

6. Screw in ventilation / oil filler plug.

Condensation drain hole

) Note!

Lenze delivers motors with condensation drain holes with sealed

condensation drain holes. The holes are sealed with a plastic plug or a

locking screw. This does not affect the type of protection and the motor is

protected against the ingress of foreign substances during transport and

operation. Further information, (¶ 64).

Loading...

Loading...