Mechanical installation

Preparation

Attachment of gearboxes with hollow shafts and keyway

4

34

Lenze ¯ MA 12.0014 ¯ 5.1

4.3.9 Attachment of gearboxes with hollow shafts and keyway

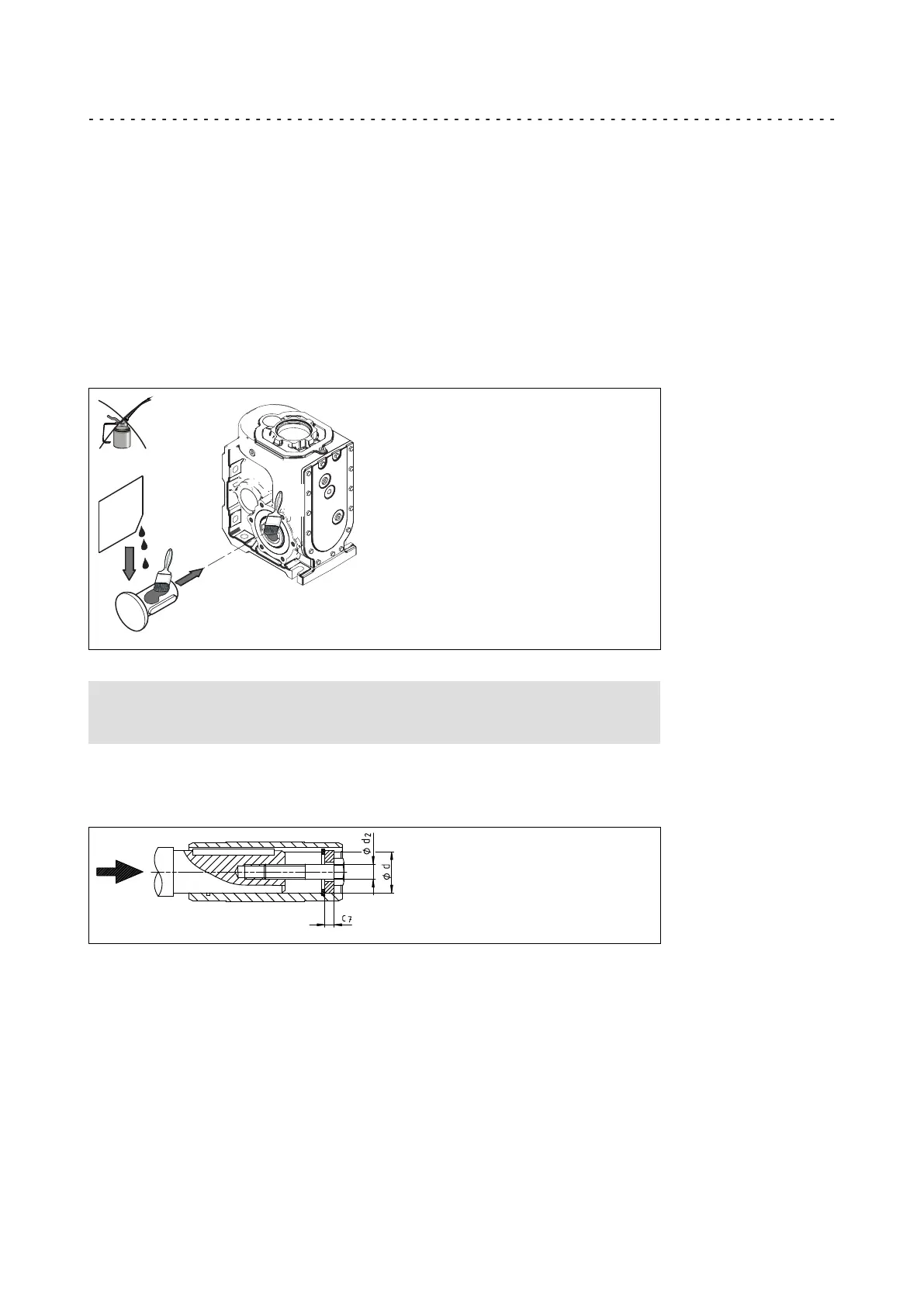

1. If necessary, remove anti−corrosion coating in the hollow shaft and on the

machine shaft.

2. Check the seat and edges of the hollow shaft and the machine shaft for damage.

Rework, if necessary. Ensure good concentricity of the machine shaft in order to

avoid unnecessary additional forces caused by tensioning.

3. Apply a fitting grease (Fig. 4) to the shaft and into the hollow shaft bore.

4. Mount gearbox with hollow shaft on the machine shaft to be driven, ensuring

exact alignment. In the mounting process, lead forces only across the hollow shaft

and not across the housing.

Paste gegen

Passungsrost

1.

4.

3.

2.

g500−B−MoPa−001

Fig. 4 Application of fitting grease against fretting corrosion

( Stop!

Take up forces only via the hollow shaft, and not via gearbox housing.

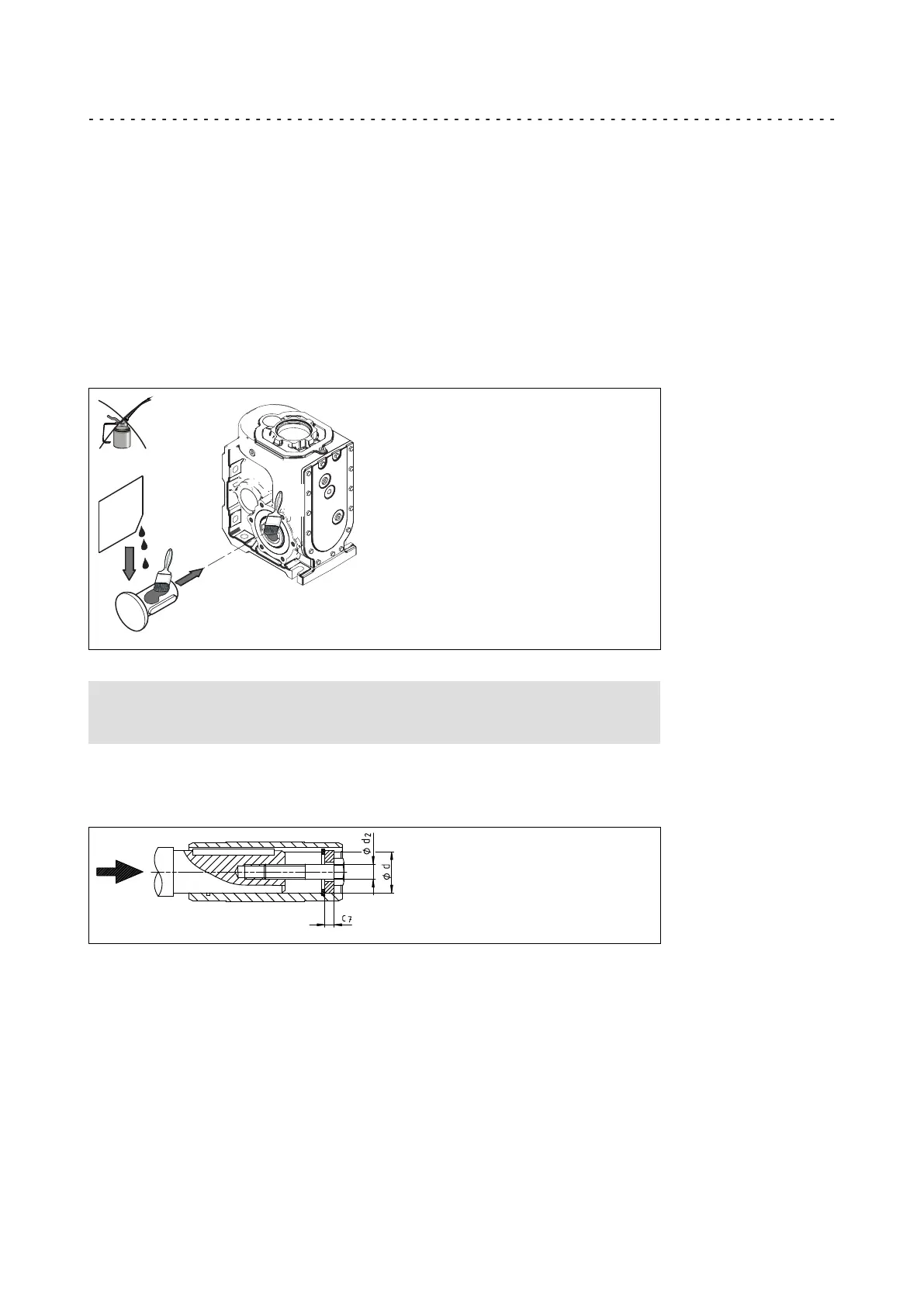

5. Secure the gearbox axially:

– The hollow shaft has snap ring grooves for axial securing. Parts used to fix the

shaft are not included in the scope of supply.

K12.0611

Loading...

Loading...