41

DATE

22.12.2003

COMPILER TECO/ATI

REG. CODE

1-5302-467

MODEL N°

50707

DATE OF ISSUE

06-95

REVISION 05

ENDORSED

VIII

69 70

71

72

DISASSEMBLY/REASSEMBLY

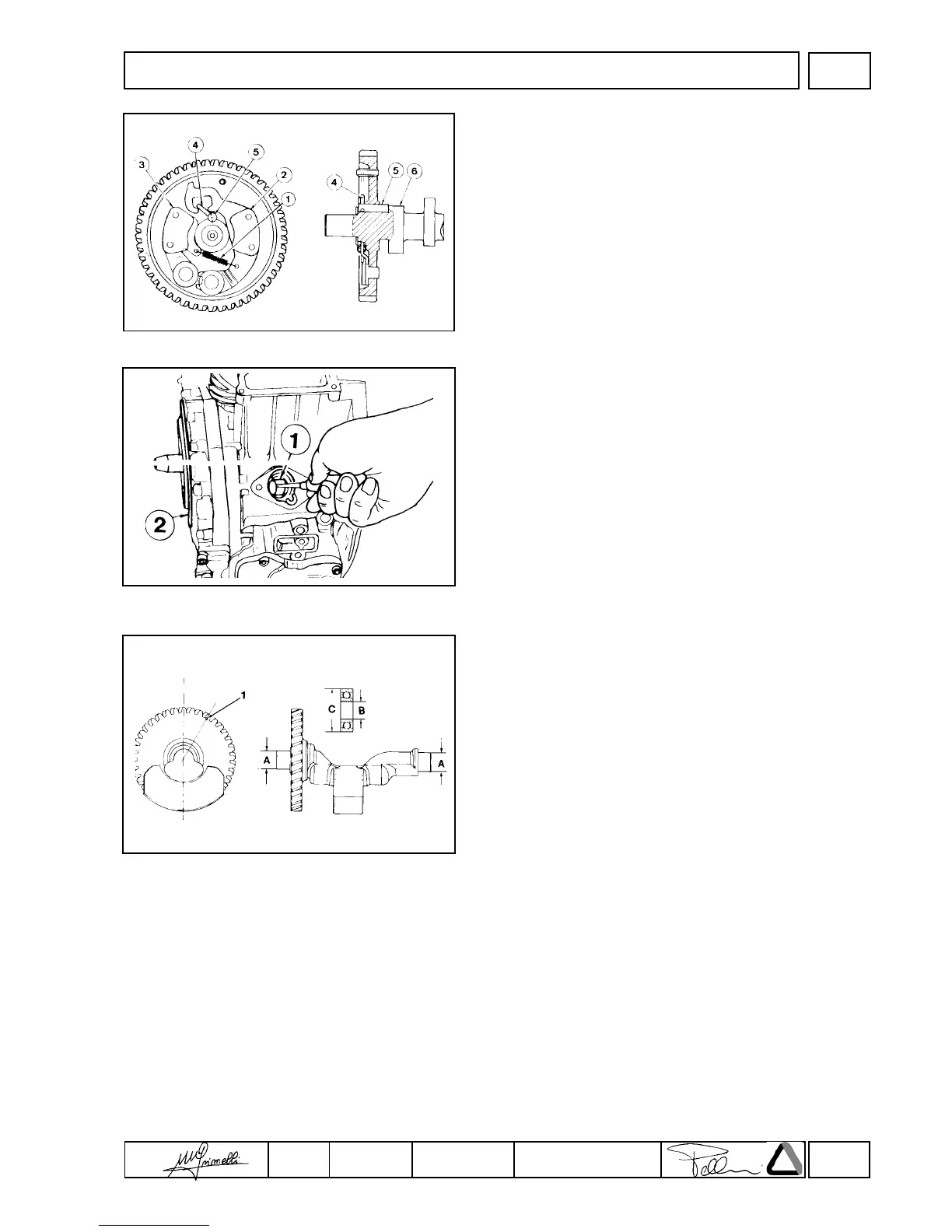

Automatic decompression

With the engine at a standstill and up to a rate of about 300 RPM,

spring 1, acting on weights 2 and 3 via lever 4 and pin 5, keeps the

exhaust valve open during the compression phase also.

Once the engine exceeds the 300 RPM rate, weights 1 and 2 keep

pin 5 in the hold position owing to the action of the centrifugal force.

In this position, cam 6 can regularly control the exhaust valve thanks

to a ridge on the pin itself.

Since there is then no compression in the cylinder, the engine will

easily start when the self-winder is used.

Camshaft end play

Perform this check before fitting cylinder head and tappets including

the injection tappets.

Temporarily fit camshaft 1 complete with washer; tighten gear cover

2 to 25 Nm.

Check end play by moving the camshaft back and forth using a

suitable tool; the end play value is 0.10÷0.25 mm and is not

adjustable.

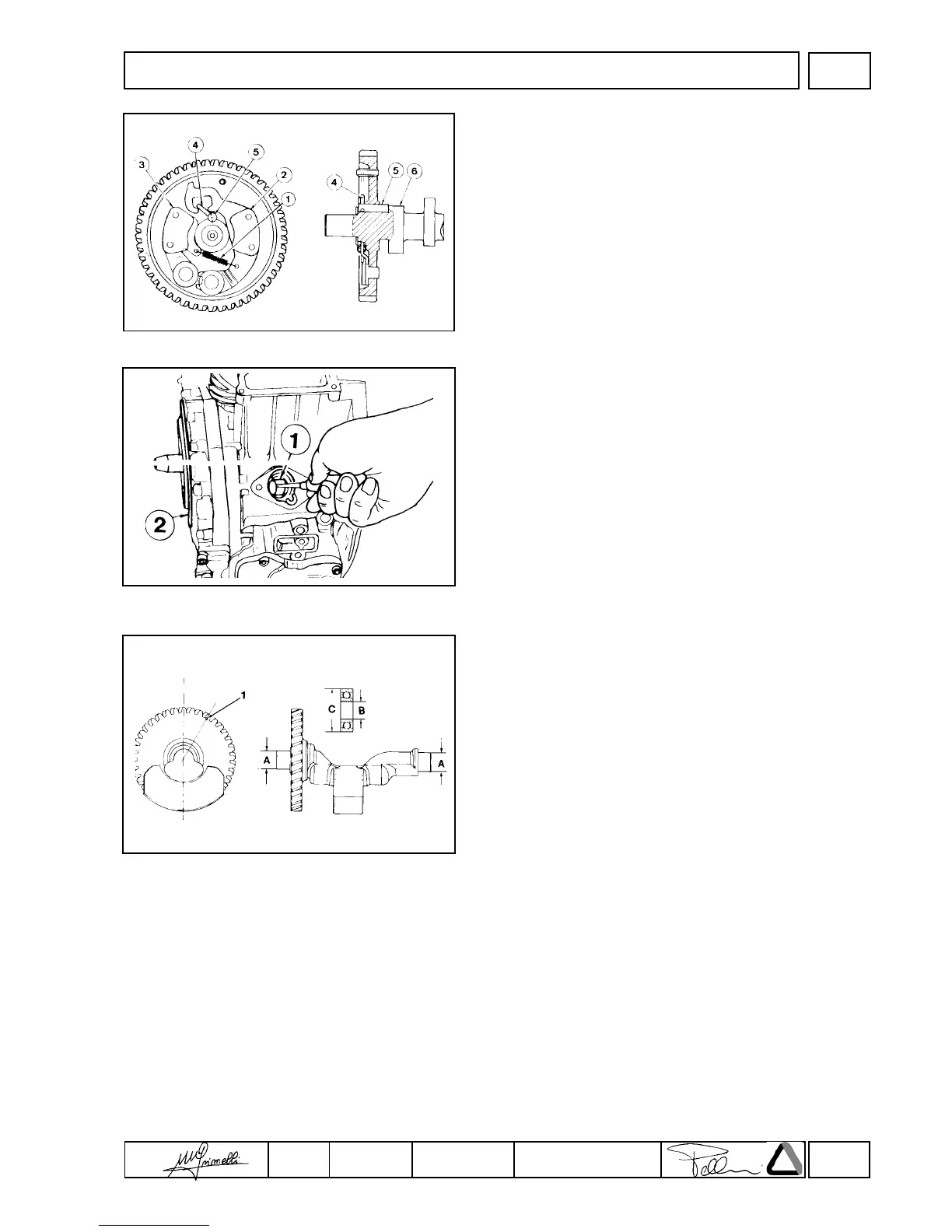

Dynamic balancer (on request)

The dynamic balancer is supported by two identical ball bearings

housed in the crankcase and in the gear cover on the timing side

respectively.

1 is the reference point for timing with the cranksaft gear (see

below).

Dimensions (mm):

A = 14.983-14.994

B = 14.99-15.00

C = 34.89-35.00

D = 34.958-34.983 (bearing housing diameter on crankcase and

gear cover on timing side).

Loading...

Loading...