49

DATE

22.12.2003

COMPILER TECO/ATI

REG. CODE

1-5302-467

MODEL N°

50707

DATE OF ISSUE

06-95

REVISION 05

ENDORSED

90 91

92

IX

93

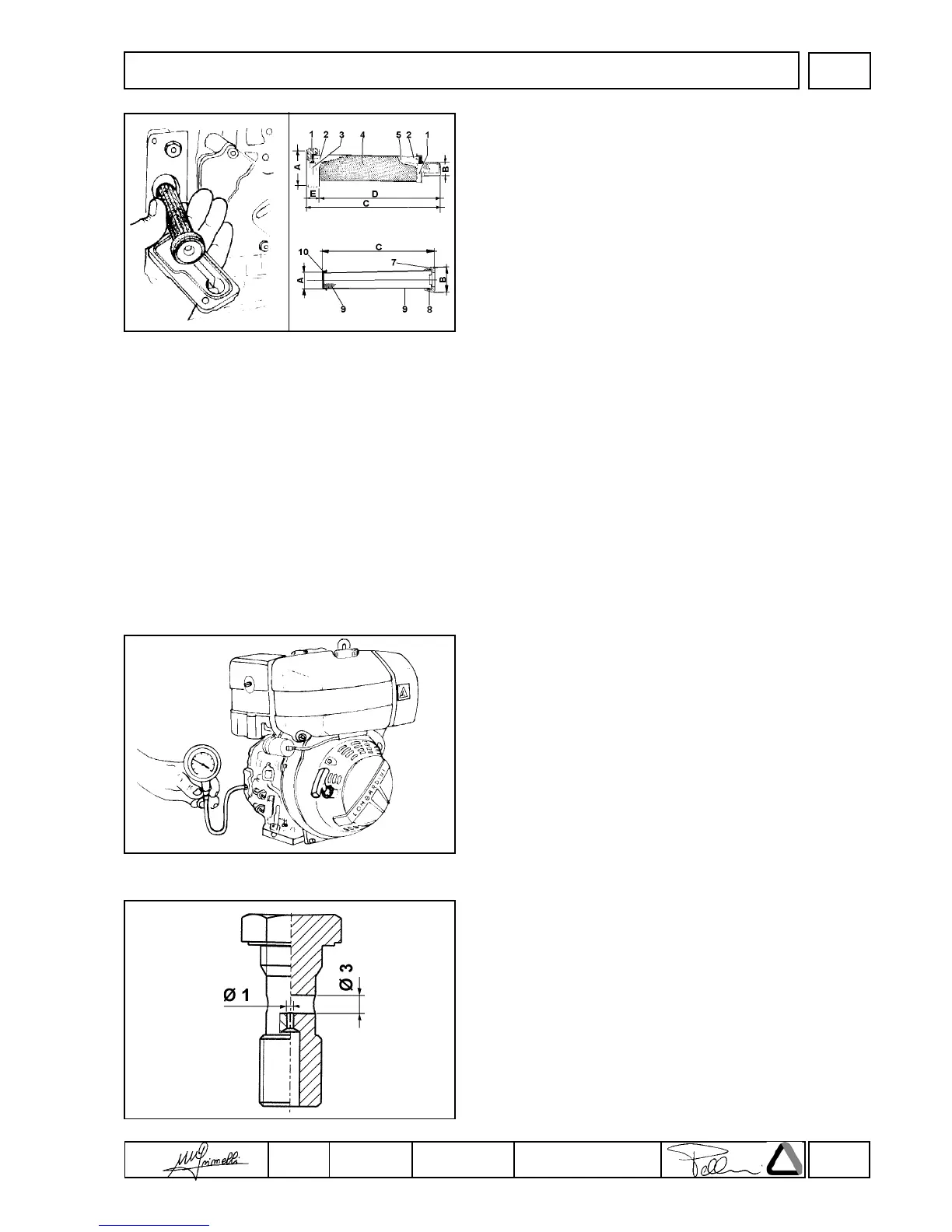

Oil filter

Filter components: 15 LD 315/350

1 Seal

2 Adhesive

3 End cap

4 Filtering material

5 Plate

Dimension mm: A = 26.5 B = 18 C = 88.5 D = 67.5 E = 8.5

Characteristics:

Useful filtering area = 75 cm

2

Degree of filtration = 50 µm.

The by-pass valve is set at 0.6-0.8 bar.

Filter components: 15 LD 225

7 Rubber pad

8 Upper cover

9 Filter element

10 Lower cover

Dimension mm: A = 19.0-19.3 B = 12.5 C = 83.0-83.5

Characteristics:

Useful filtering area ≥ 75 cm

2

Degree of filtration = 40-60 µm.

See page 18 for the replacement frequencies.

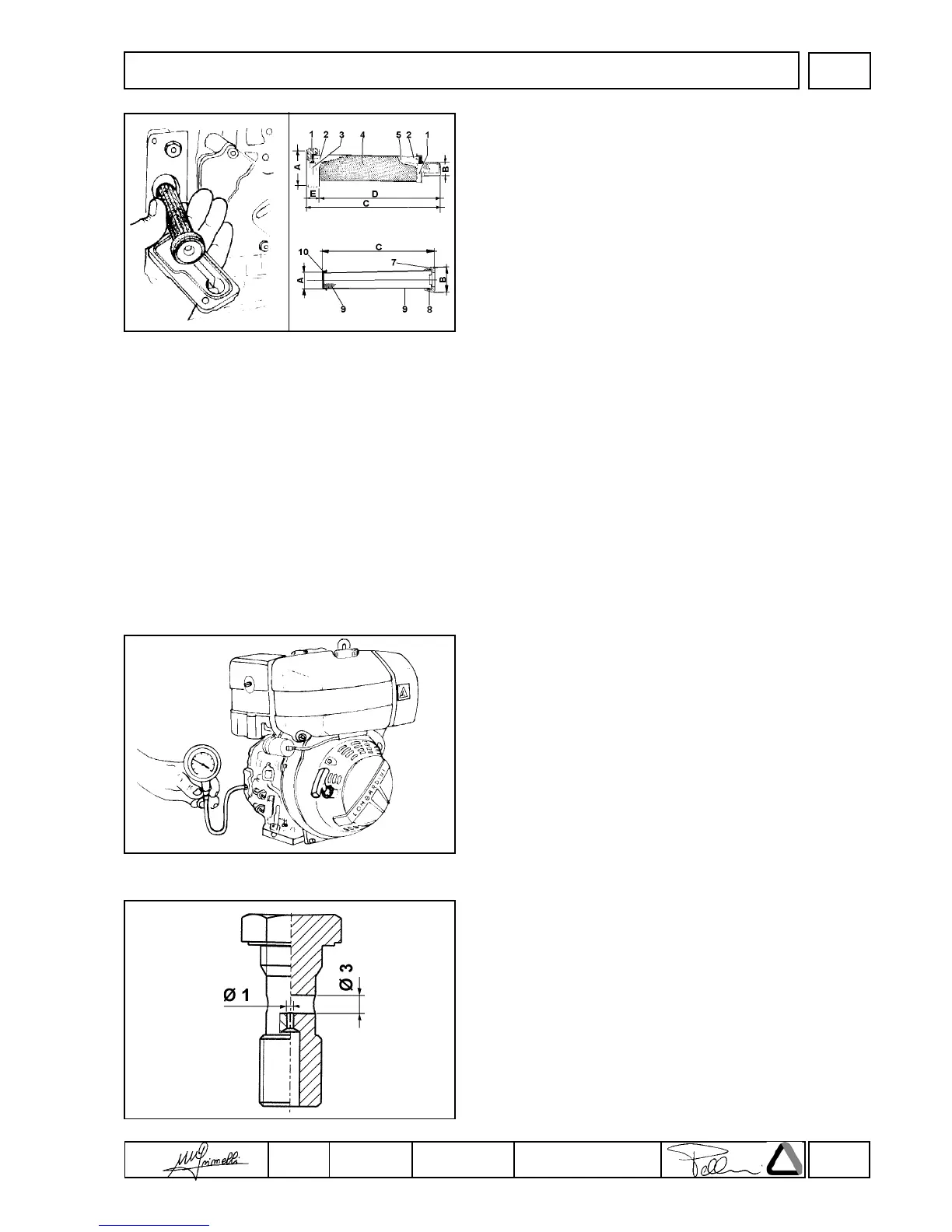

Oil pressure check

When assembly operations are completed fill engine with oil and

fuel; connect a 10 bar pressure gauge to the oil filter fitting.

Start the engine and check pressure as a function of the oil

temperature (see below).

Calibrated pipe for lubrication of hydraulic tappets

The pipe is fitted to the hydraulic tappets oil line (see fig. 83, detail

11).

If the calibrated hole is clogged, the tappets are not sufficiently

lubricated, valve clearance is therefore increased and the engine

may be noisier.

If the diameter of the calibrated pipe is larger than the ones given

in picture 93, the pressure exerted by the hydraulic tappets may

cause the valves to remain open even during the compression

phase.

LUBRICATION SYSTEM

Loading...

Loading...