53

DATE

22.12.2003

COMPILER TECO/ATI

REG. CODE

1-5302-467

MODEL N°

50707

DATE OF ISSUE

06-95

REVISION 05

ENDORSED

X

101

102

103 104

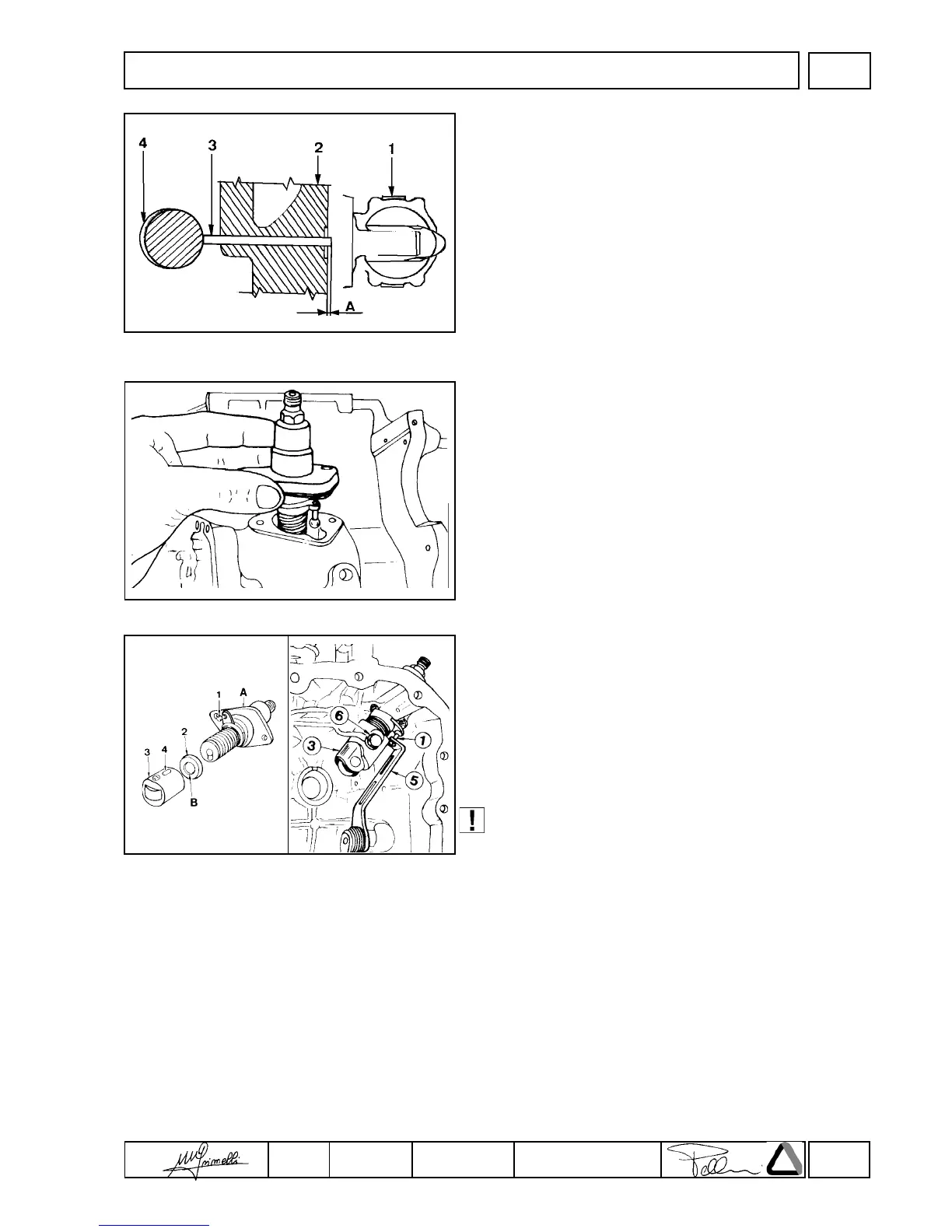

Fuel pump, drive rod protrusion

Components:

1 Fuel pump

2 Crankcase

3 Drive rod

4 Eccentric

Check while eccentric 4 is at rest (lowest point of travel).

Protrusion A of drive rod 3 is 1.5-1.9 mm; it is not adjustable.

Drive rod length = 58-58.2 mm for 15 LD 225

Drive rod length = 65.8-66.0 mm for 15 LD 315/350

Drive rod length = 61,4÷61,6 mm for 15 LD 400/440

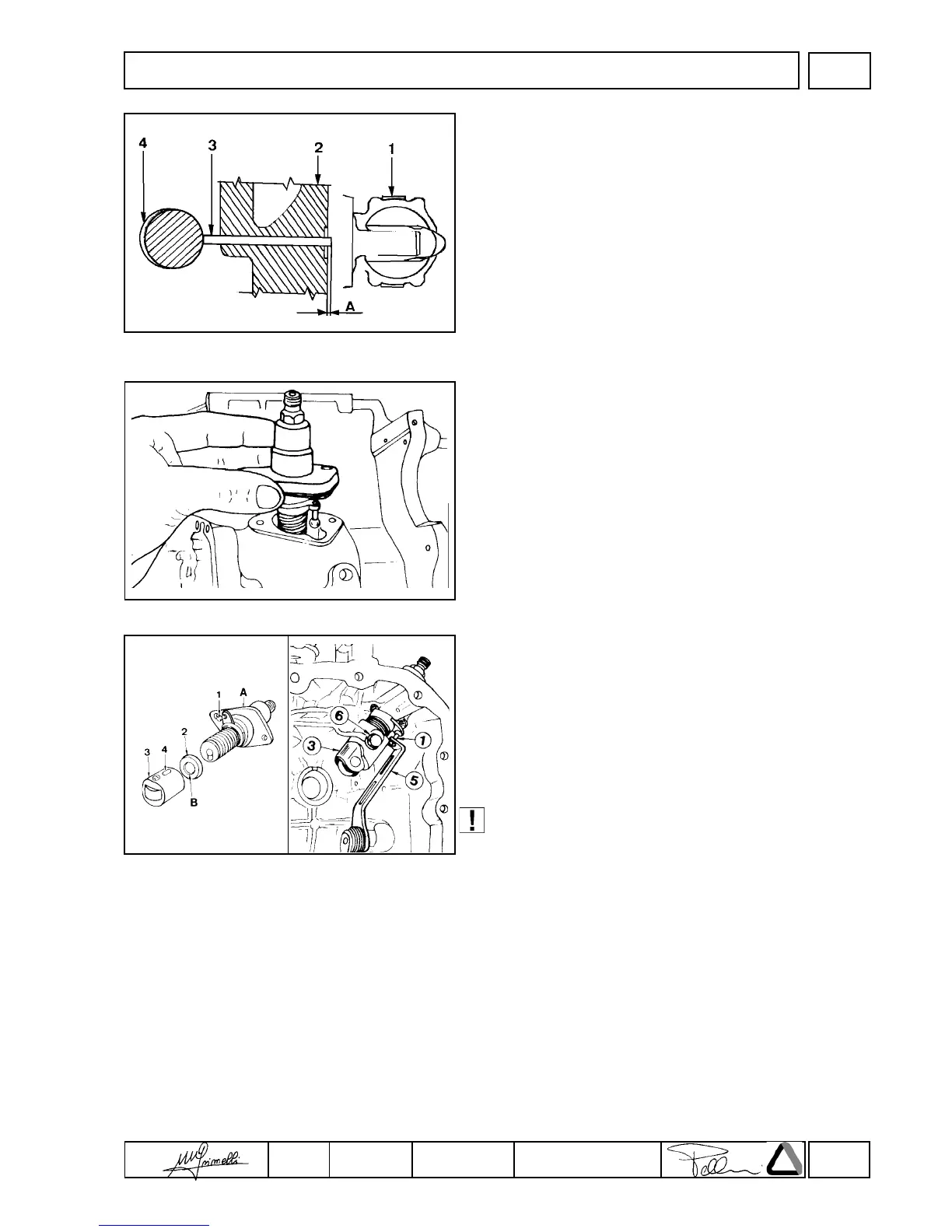

Injection pump

This is of the simplified QLC type; it is housed in the crankcase

and is controlled by the camshaft via tappets.

Injection pump fitting in the crankcase

Fit tappets 3 so that screw 6 is introduced into guide 4.

Tighten screw 6 to 9 Nm and check that the tappet is free to move

downwards.

Fit pad 2 into the tappet so that recess B points downwards as

shown in the figure.

Fit the injection pump into the crankcase complete with gasket (C)

position8ing flow control 1 in the fork of lever 5 which should be in

the maximum flow position.

When removing the injection pump from its housing make

sure that spacer 2 is not dropped into the oil sump;

injection pump operation will be impaired uf the spacer is

not installed.

FUEL SYSTEM

Loading...

Loading...