COMPILER TECO/ATL

REG. CODE

1-5302-351

MODEL N°

50563

DATE OF ISSUE

04.90

REVISION 04

ENDORSED

DATE

15.11.99

35

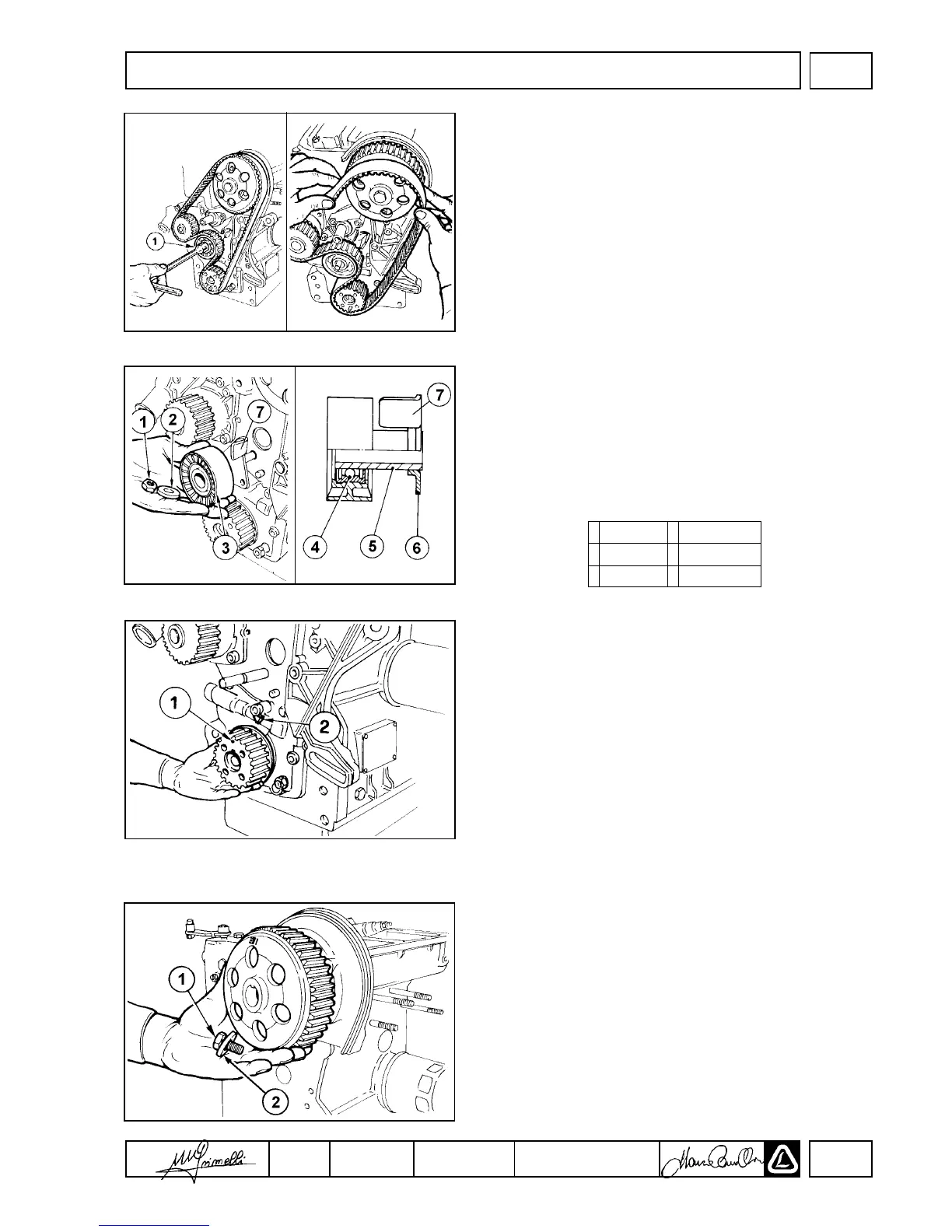

TIMING BELT REMOVAL

REMOVAL: Loosen nut (1). Slide the timing belt off of the pulleys.

NOTE 1.: Timing belt refitting can be greatly simplified if the engine

is rotated until the timing marks align prior to removing the timing

belt.

NOTE 2.: Discard the timing belt after removal irrespective of

operational hours. Timing belts take a “set” during operation and

subsequent reinstallations will not allow replacement in the identical

position as prior.

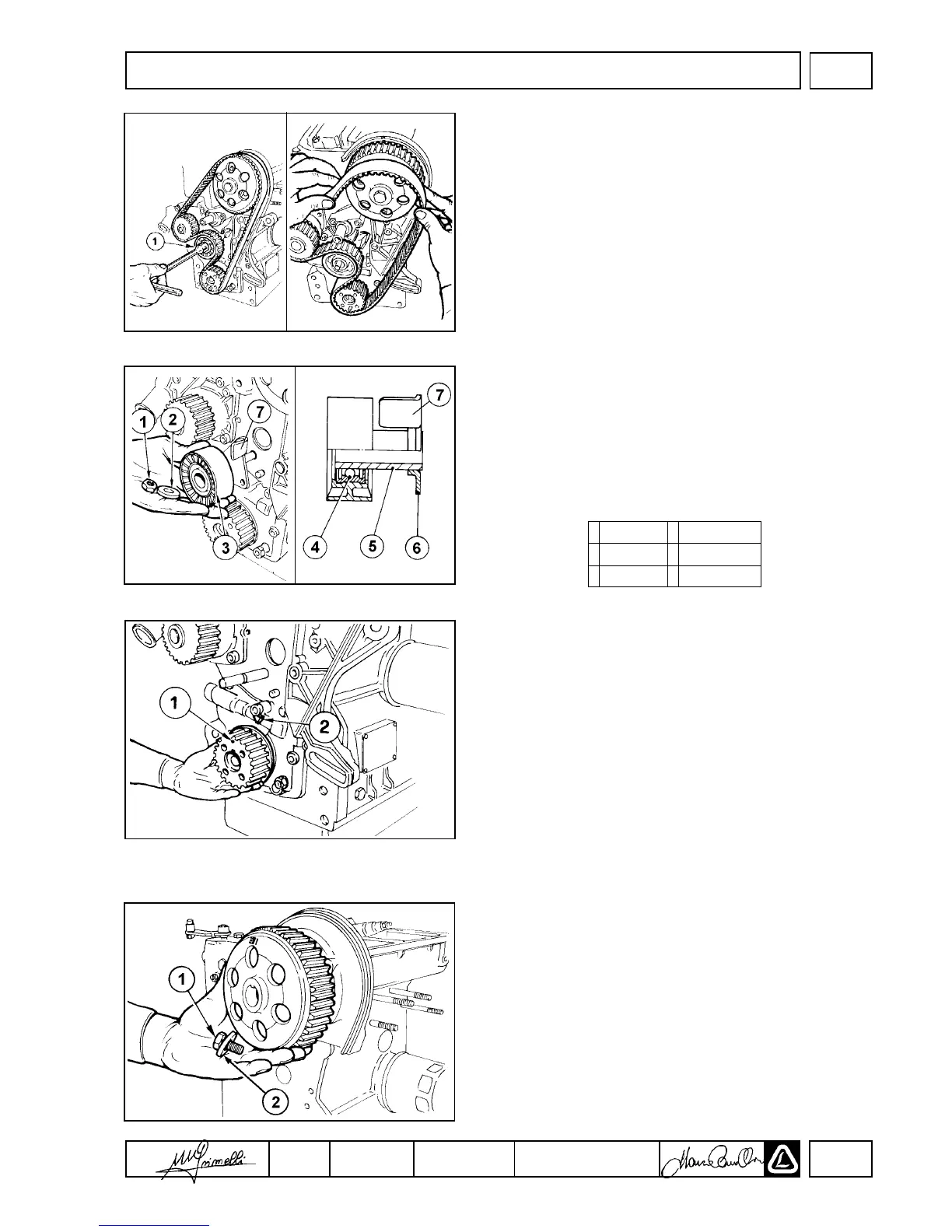

IDLER PULLEY

REMOVAL: Remove nut (1) and washer (2). Remove the idler pulley

assembly from the engine.

INSPECTION: Inspect the pulley idler surface for chips, wear,

degradation, etc. Check the bearing for radial run-out and smooth

operation. Replace the bearing, pulley or assembly as required.

Components:

CRANKSHAFT TIMING PULLEY

REMOVAL: Slide pulley from the crankshaft.

INSPECTION: Clean the pulley in solvent. Dry with compressed air.

Inspect the pulley for chips, tooth profile wear and cracks. Inspect

the keyway for fretting or indications of loose operation. Inspect the

crankshaft for signs of fretting at the keyway. Inspect the key

condition. Replace components as required. Remove all rust and

deposits from the crankshaft.

INSTALLATION: Slide the clean timing pulley onto the crankshaft

aligning the keyway in the pulley with the key on the crankshaft.

NOTE: Reference mark (1) on the crankshaft timing pulley and

reference mark (2) on the oil pump housing are timing marks. When

aligned, No. 1 piston (flywheel side) is at TDC.

CAMSHAFT TIMING PULLEY

REMOVAL: Loosen and remove bolt(1) and washer(2). Slide the

camshaft pulley from the camshaft.

INSPECTION: Clean the pulley in solvent. Dry with compressed air.

Inspect the pulley for chips, tooth profile wear and cracks. Inspect

the keyway for fretting or indications of loose operation. Inspect the

seal race on the backside of the pulley for excessive grooving,

erosion or roughness. Replace as required.

INSTALLATION: Coat the seal race of the camshaft pulley with clean

engine oil. Install the camshaft pulley onto the camshaft taking care

not to damage the camshaft seal. Install the washer (2) onto the bolt

(1). Torque the camshaft retaining bolt to 80 Nm.

1 Nut 4 Bearing

2 Washer 5 Shaft/ Support

3 Pulley 6 Mounting Plate

DISASSEMBLY/REASSEMBLY

II

Loading...

Loading...