REG. CODE

1-5302-351

MODEL N°

50563

DATE OF ISSUE

04.90

REVISION 04

DATE

15.11.99

ENDORSED

COMPILER TECO/ATI

36

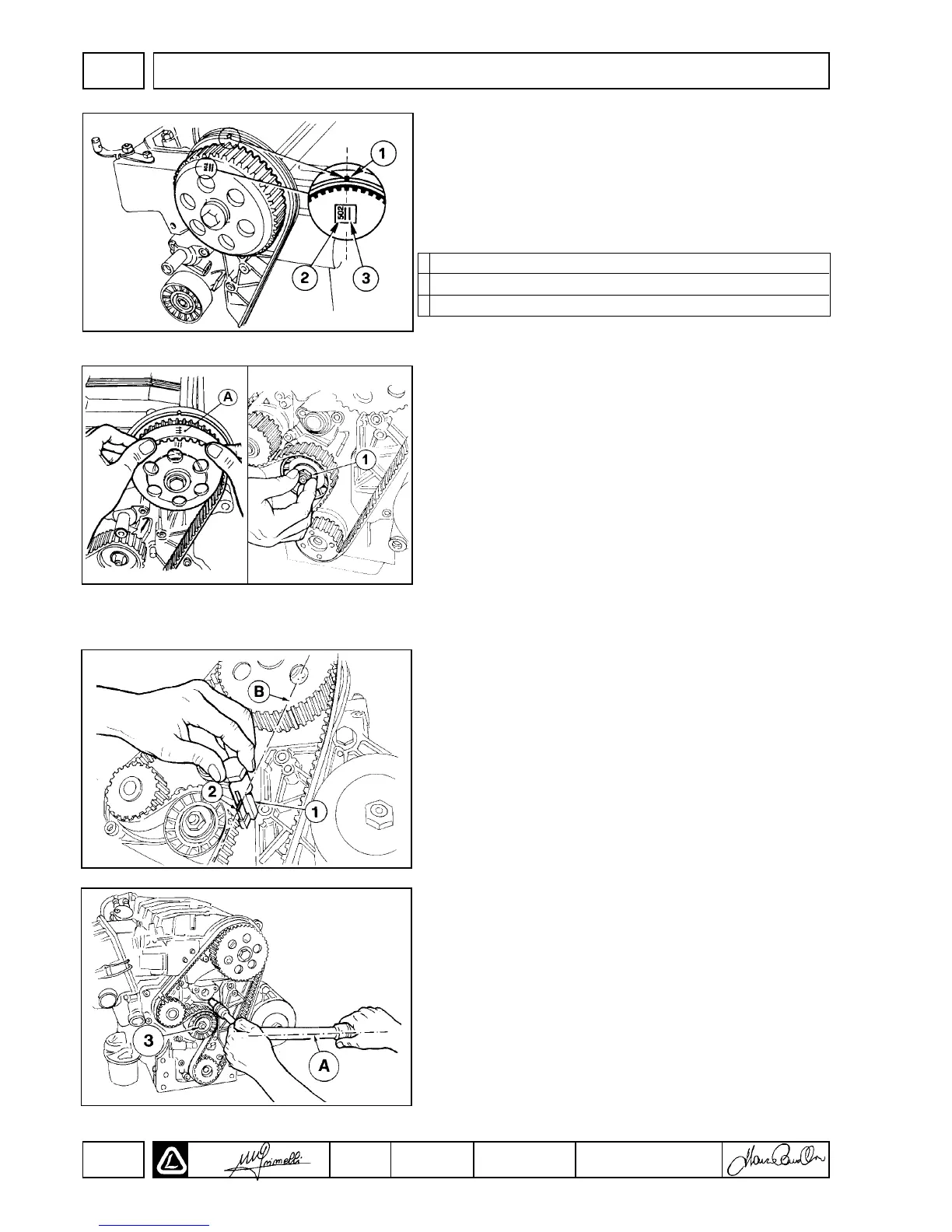

TIMING PULLEY - REFERENCE MARKS

All LDW-FOCS engines (502, 602, 903, 1204 and 1204/T) utilize the

same camshaft timing pulley. The cam timing of the LDW 502

however, differs from the other LDW-FOCS engines. Carefully review

the diagram to the left and the chart below to assure the correct

timing marks are used with respect to the engine model.

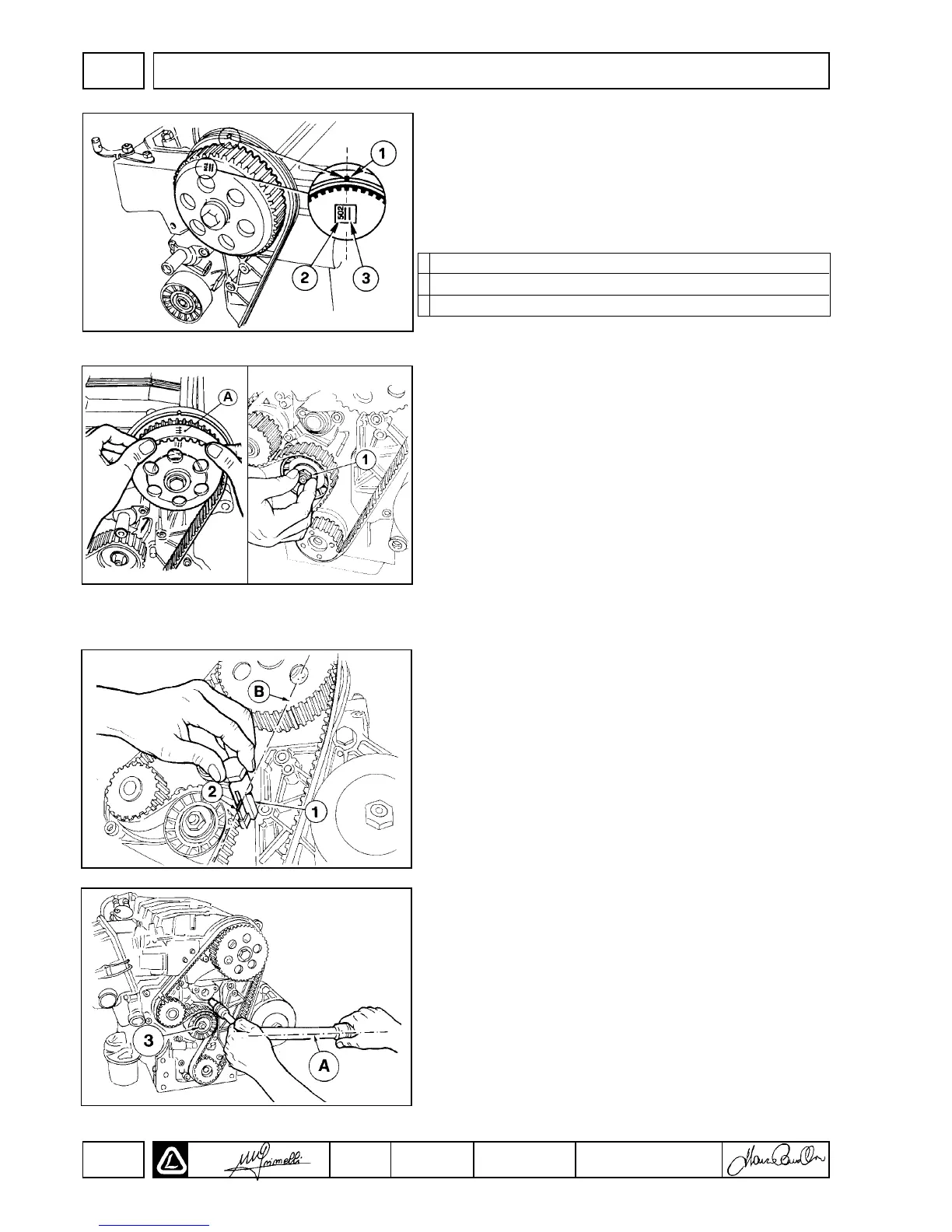

TIMING BELT INSTALLATION- TIMING PROCEDURE

With reference to the Crankshaft Timing Pulley section on the

previous page, align the crankshaft timing pulley mark with the TDC

reference mark on the oil pump housing. Align the camshaft timing

pulley with the timing reference mark as detailed above.

Loosen the timing belt idler pulley (see page 24). Orient the new

timing belt with the directional marks(A) as shown. Install the timing

belt onto the engine routing the timing belt over the crankshaft pulley,

over the camshaft pulley, over the coolant pump pulley and finally

around the idler. Push the timing belt against the back of the

crankshaft pulley and align the timing belt on all other pulleys. Pivot

the timing belt idler by hand and slightly tension the belt. Hand

tighten the tensioner nut, then loosen the nut by 1/2 turn.

TIMING BELT TENSIONING PROCEDURE- SETUP

Position belt preload tool 1460-049 (1) over the timing belt idler

adjustment ear (2). The tool should be oriented so that parallelism

with axis (B) is attained.

TIMING BELT TENSION PROCEDURE

Position a torque wrench as shown, engaging the 1460-049 tension

tool. The torque wrench axis (A) should be 90° from axis (B) as

shown above. Tension the belt by applying a torque of 30 Nm. While

holding the torque at 20 Nm, tighten the idler nut (3) securely. Torque

nut (3) to 40 Nm.

Rotate the engine in the normal direction of rotation (CW when

viewed from fan end of engine) three(3) complete revolutions to allow

the timing belt to “seat” and to align perfectly.

Repeat the above procedure two(2) times, including rotating the

engine to allow complete and confident tensioning.

1 Timing Reference Mark on Cylinder Head.

2 Camshaft Pulley Timing Mark- LDW 502 Only.

3 Camshaft Pulley Timing Mark- LDW602,702,903,1003,1204,1404 and 1204/T

DISASSEMBLY/REASSEMBLY

II

Loading...

Loading...