REG. CODE

1-5302-351

MODEL N°

50563

DATE OF ISSUE

04.90

REVISION 04

DATE

15.11.99

ENDORSED

COMPILER TECO/ATI

52

CONNECTING BEARING / ROD CAP INSTALLATION

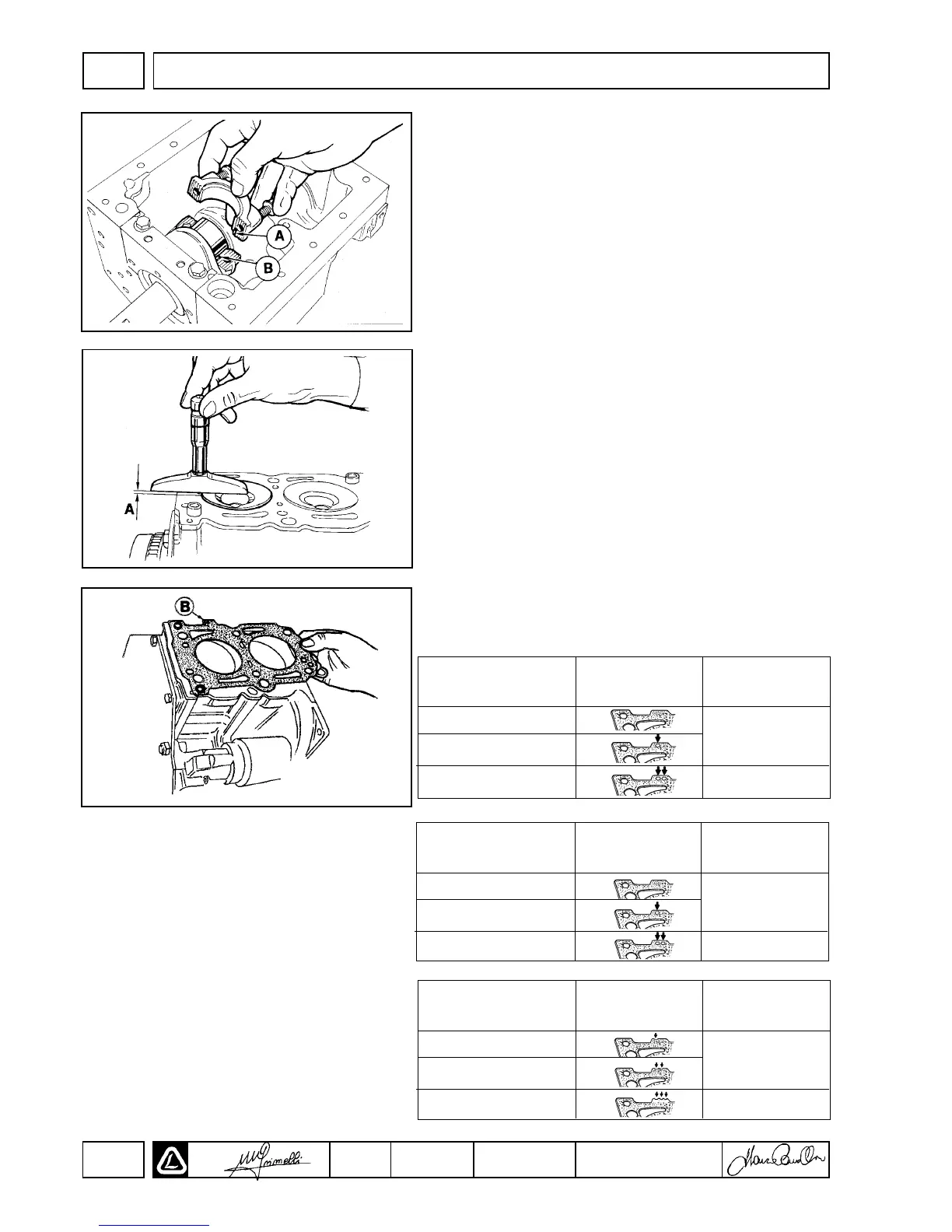

Install the connecting rod bearing inserts into the connecting rod and

connecting rod cap. Make sure that the back of the bearing insert and

the connecting rod and connecting rod cap bore is free of dirt, rust,

oil etc. Insert the bearing inserts so that the tab on the bearing aligns

with the slot in the connecting rod or connecting rod cap. Push the

bearing completely into the connecting rod and connecting rod cap.

Liberally oil the bearings with clean engine oil. Install the connecting

rod cap onto the connecting rod making sure that the respective

tang/slot locks on the connecting rod cap aligns with the tang/ slot

lock on the connecting rod.

Torque the connecting rod bolts to 40 Nm in 5 Nm steps.

PISTON PROTRUSION

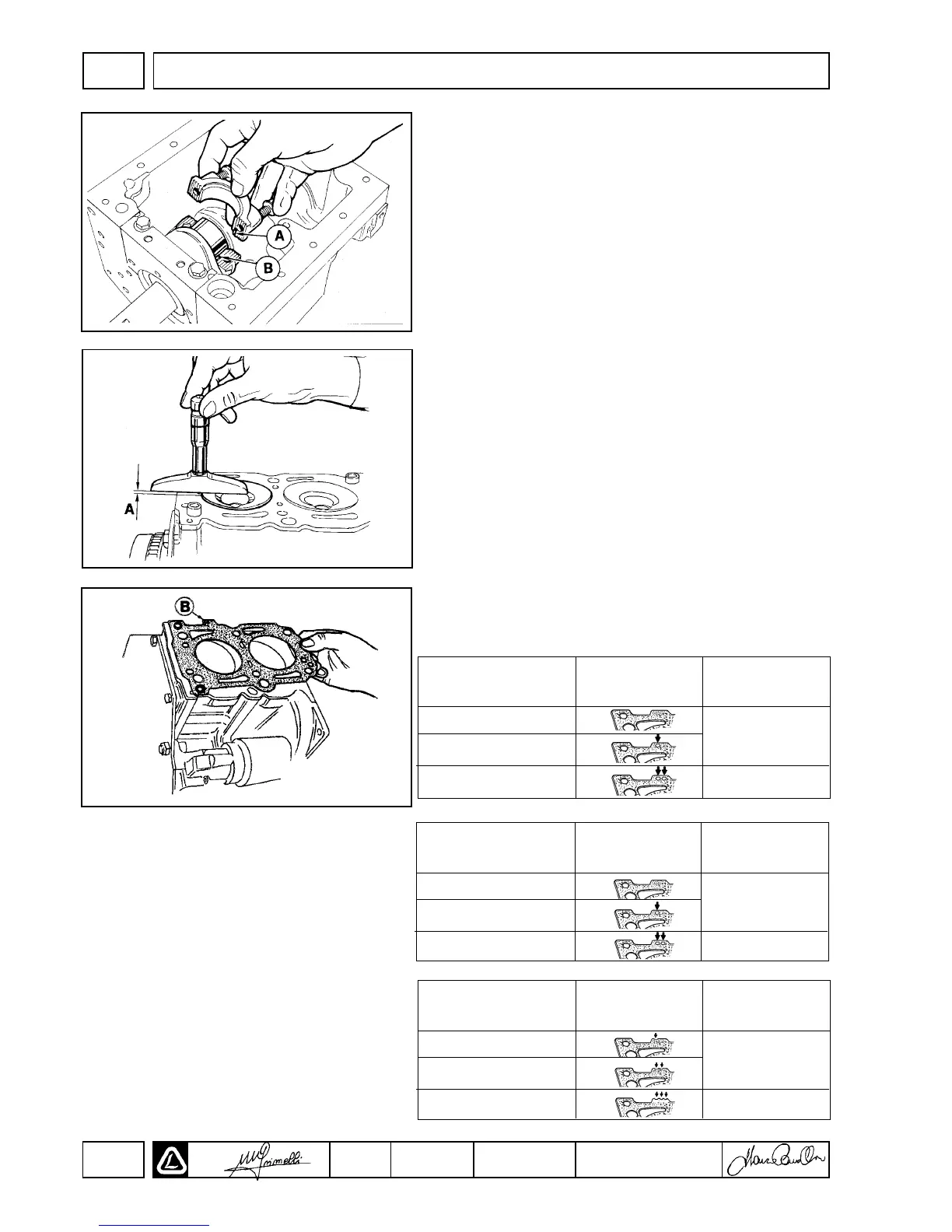

Rotate each cylinder to exact TDC. TDC may be determined by the

use of a dial indicator mounted to the cylinder deck and indicating

piston height as a function of crankshaft rotation.

After TDC is established, measure the protrusion of the piston (A)

from the cylinder deck plane using a calibrated depth micrometer.

The height should be measured on a line corresponding to the wrist

pin axis as shown. Record the protrusion. Repeat the TDC

establishment and piston protrusion procedure for each cylinder,

recording the value for each cylinder. The HIGHEST protrusion

measured will be used to establish the proper head gasket selection

as presented below.

HEAD GASKET SELECTION/ INSTALLATION

Three(3) separate head gasket thickness’ are available for FOCS

engines depending on the measured piston protrusion as measured

above. The head gaskets are identified by notches cut in the edge

located at point (B) as detailed below. Head gaskets are provided

with “0 notch”, “1 notch” or “2 notches” to

For 502,602,903,1204,1204/T

For 702,1003

For 1404

assist in the identification of the different gaskets.

A (mm)

(PISTON PROTRUSION) No. of hole Piston to Cylinder

Head Clearance (mm)

0.97/1.06

1.07/1.16

1.17/1.25

0

1

2

Match the piston protrusion dimension determined

above with dimension(A) from the chart. Install the

corresponding head gasket. If a head gasket cannot

be chosen based upon the piston protrusion

measured, check the connecting rod length, rod

bearings, wrist pin bushing, etc. for the cause of the

problem.

Completely clean the deck surface of oil, old gasket

material, varnish, coolant, etc. Remove all traces of

fluid from the cylinder head bolt bores. Install the

head gasket so that the gasket aligns with the deck

dowels and the brand name or “TOP” printed on the

gasket faces up.

A (mm)

(PISTON PROTRUSION) No. of hole Piston to Cylinder

Head Clearance (mm)

0.82/0.91

0.92/1.01

1.02/1.10

0

1

2

A (mm)

(PISTON PROTRUSION) No. of Notches Piston to Cylinder

Head Clearance (mm)

0.82/0.91

0.92/1.01

1.02/1.10

1

2

3

0.39/0.48

0.40/0.48

0.54/0.63

0.55/0.63

0.52/0.61

0.53/0.61

DISASSEMBLY/REASSEMBLY

II

Loading...

Loading...