UNDERCARRIAGE RT765E-2 SERVICE MANUAL

8-4

Published 9-04-2014, Control # 422-08

Wheels and Tires

Description

The standard tire size for this unit is 29.5 x 25; also available

as an option, is a 29.5R25 tire.

Each wheel assembly (tire and rim) is mounted on the

planetary hub with 24 grade 8 lug nuts.

NOTE: The tire diameters, widths, and weights may vary

slightly depending on the tire manufacturer.

Off-highway tires are designed to operate with a certain

sidewall deflection or bulge. Correct air pressure ensures

prior deflection which, in turn, ensures proper traction,

flotation, support of load, and prevents excessive flexing of

the tire. Over inflation increases rim stresses, which results

in lowered rim life.

Refer to and adhere to the inflation pressures in the Load

Chart Book in the crane cab.

Maintenance

Mounting Wheel Assemblies

NOTE: Do not lubricate the wheel studs or lug nuts.

1. Raise the crane on outriggers so the wheels are off the

ground.

NOTE: Prior to wheel installation remove any dirt or grease

from wheel mounting surfaces.

2. Position the wheel assembly on the mounting studs.

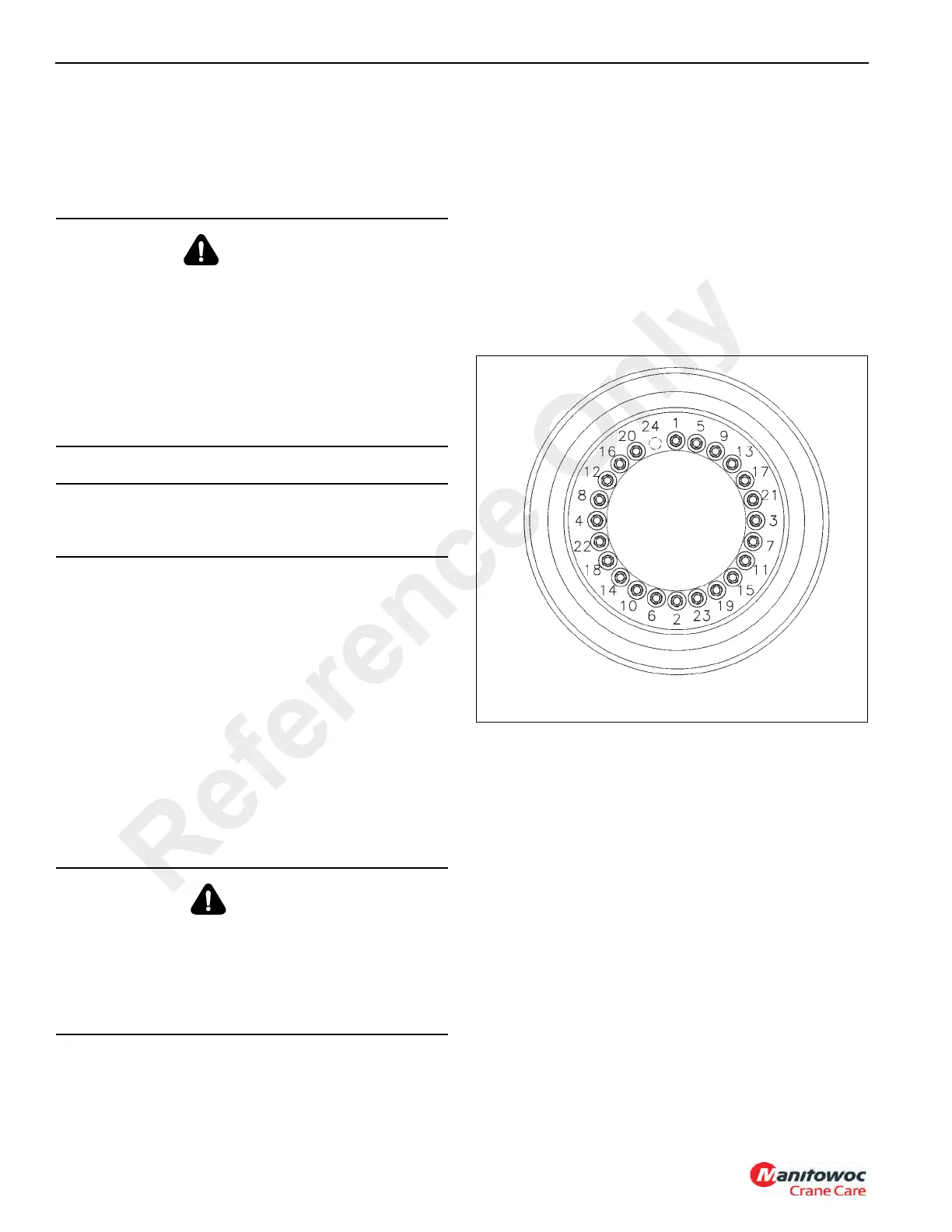

Install the lug nuts and tighten them to 50 lb-ft (68 Nm) in

the sequence shown in Figure 8-2.

3. Ensure the wheel assembly is positioned properly on the

hub.

4. Continue to torque the lug nuts 340 to 360 lb-ft (461 to

488 Nm) in the sequence shown in Figure 8-2.

5. Lower the crane onto its tires. Retract and stow the

outrigger assemblies and the floats.

6. Road-test the tire, then retorque to 340 to 360 lb-ft (461

to 488 Nm).

7. Maintain proper torque on wheel lugs and check for

proper wheel mounting. Retorque the lug nuts 50 to 100

miles (80 to 160 km) after the wheels are removed and

reinstalled. This will reseat the lug nuts. Check the

torque every 500 miles (800 km) thereafter.

Typical Wear Patterns

Incorrect Tire Pressure

Too high air pressure Figure 8-3, View 1) gives rapid wear in

the middle of the tire. Too low air pressure (Figure 8-3, View

2) gives rapid shoulder wear.

WARNING

Possible equipment damage and/or

personal injury!

Driving the crane with a tire under inflated at 80% or less

of its recommended pressure can cause the wheel and/or

tire to fail. Per OSHA Standard 1910.177(f)(2), when a tire

has been driven under inflated at 80% or less of its

recommended pressure, it must first be completely

deflated, removed from the axle, disassembled, and

inspected before re-inflation.

CAUTION

Do not mix tires or rims from different manufacturers.

Vehicle stability can be affected.

DANGER

Do not attempt to demount or mount tires without proper

training. The high pressures involved can cause tire and

rim parts and tools to fly with explosive force, if proper

procedures are not used, causing severe injury or death

to personnel and damage to the crane and surrounding

area.

Reference Only

Loading...

Loading...