MAKING THE FRONT PANEL CUTOUT

The panel is cut out using the "FRONT

PANEL CUTOUT TEMPLATE." To position

the template on the front of the panel, make

two locating holes from the back (inside) of

the panel using one of the mounting strips

(½ inch by 3½ inches) as a measuring tool.

Proceed as follows:

Scribe a vertical center line through the

exact center of the proposed cutout area

from the top of the panel to the top surface

of the shelf as illustrated in "A," Figure 3.

Using one of the mounting strips as a meas-

uring tool, draw a horizontal line 3½ inches

above the shelf. (See "B," Figure 3.) Place a

mounting strip along the horizontal line to the

left of the vertical center line and mark a

point 3½ inches left from the vertical center

line. Repeat this procedure and mark a point

3½ inches to the right of the vertical center

line. These points should now be 3½ inches

up from the top of the shelf and 7 inches

apart, one 3½ inches to the left and one

3½ inches to the right of the vertical center

line. (See "C," Figure 3.) Drill a

3

/

16

inch hole

at each point. Hold the drill perpendicular to

the front panel so that the hole will be located

accurately on the front of the panel.

Position the template on the front of the

panel using the two locating holes to line it

up correctly. Scribe the rectangular opening

on the front panel and mark the position of

the six mounting holes. Drill the six

3

/

16

inch

mounting holes before cutting the panel

opening. Then cut out the opening. It is im-

portant that the cutout be just with in the lines.

SHELF MOUNTING

If the installation requires a shelf, proceed

as follows: Locate the center of the shelf and

scribe a line from front to back. The "SHELF

CUTOUT PLATE" is marked for panel thick-

nesses from ¼ inch to 1 inch. Fold the tem-

plate on the line that corresponds to the

thickness of the panel. Place it on the shelf

so that it butts against the inside of the panel.

Match the center line mark on the template

to the scribed center line on the shelf. Mark

the position of the four drill holes. Drill the

four ¼ inch holes.

INSTALLING THE C11

Remove the four screws holding the C11

to the shipping pallet. (Save these screws,

you will need them if your cabinet has a ¼

inch or

3

/

8

inch shelf.) Remove the four plastic

feet from the bottom of the C11.

In the mounting hardware package are

four 6-32 flathead screws and eight 6-32

roundhead screws. Two of the flathead

screws of the proper length are used to at-

tach the mounting strips to the cabinet. Four

of the roundhead screws of the proper length

are used to attach the C11 to the cabinet and

mounting strips. The 6-32 x ½ inch screws

are to be used with panels ½ inch to 1 inch

in thickness.

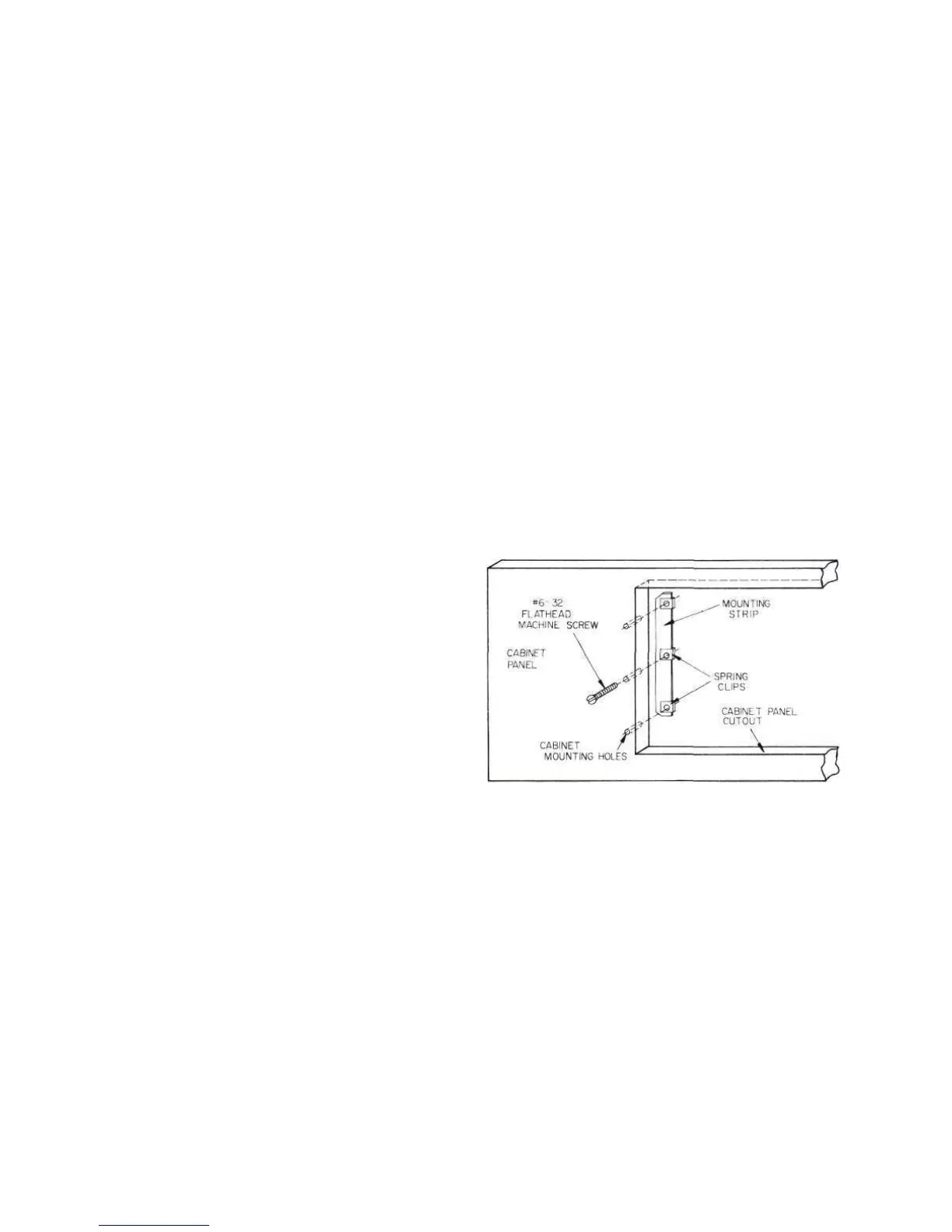

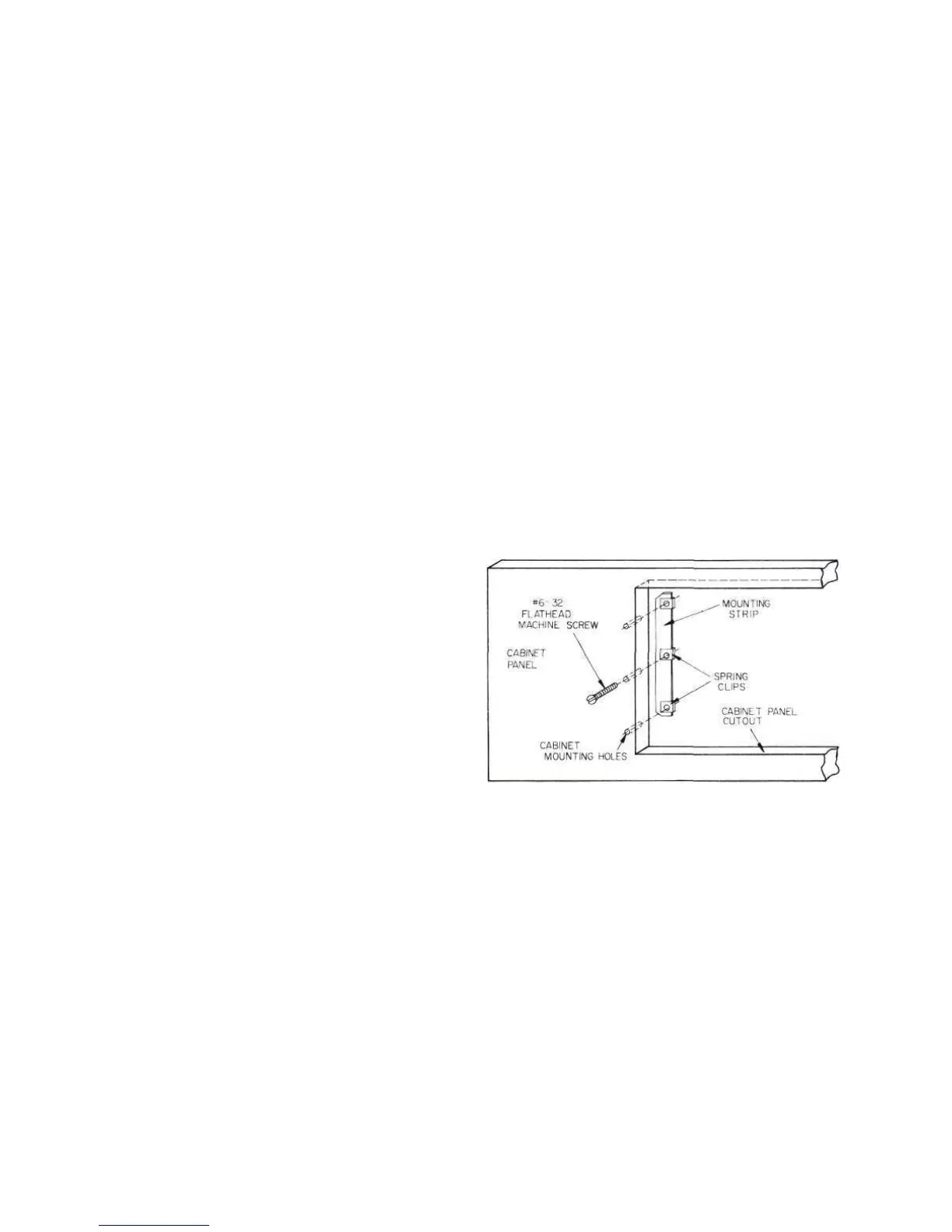

Select the proper length 6-32 flathead

screws and use them to install the two mount-

ing strips behind the front panel. Be sure

that the edge of the strip with the clips is

toward the panel opening. Line up the mount-

ing strips on each side of the front panel

cutout so the three holes in the strip are in

line with the three holes in the panel. (See

Figure 4.) Install the proper length flathead

screws in the center hole of each strip. Drive

them in so the flatheads are flush with the

panel; if necessary, countersink the two

center holes.

Figure 4. Securing the Mounting Strip to the Front Panel

Carefully insert the C11 through the front

of the panel opening so that it rests on the

shelf. Insert the proper length 6-32 round-

head screws into the four holes in the mount-

ing flanges on each end of the tuner front

panel. Drive them in, but do not tighten.

If the cabinet is fixed and will not be

moved about, it is not necessary to secure

the C11 chassis to the shelf. If the cabinet is

to be moved about, it is recommended that

the C11 chassis be secured to the shelf. The

four 10-32 x ½ inch screws used in shipping

are supplied for use if the shelf is under

3

/

8

inch. Use the 10-32 x ¾ inch screws if this

shelf is V2 inch or

5

/

8

inch thick and the 10-32

x 1 inch screws if the shelf is ¾ inch or

7

/

8

7

Loading...

Loading...