IM 781-2 Page 53

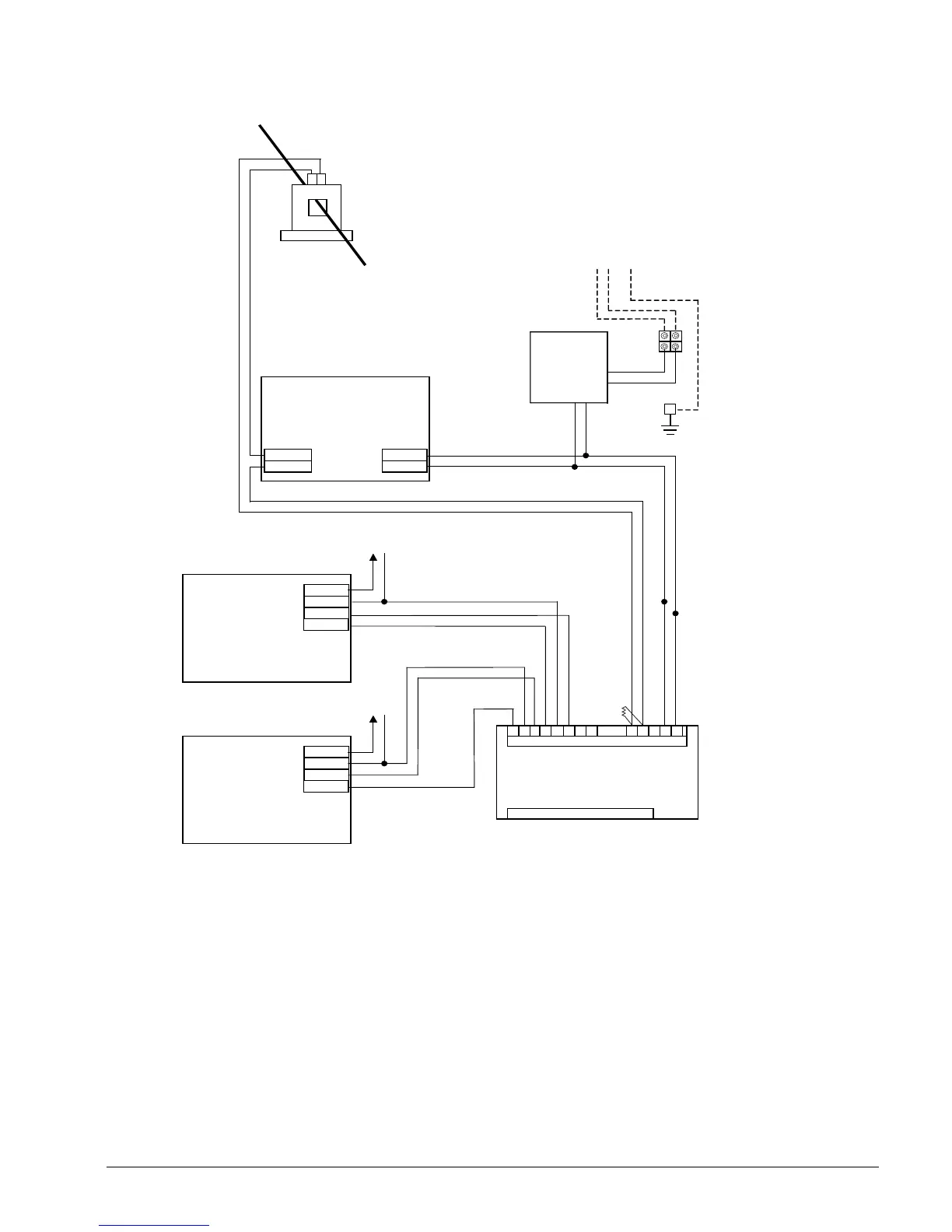

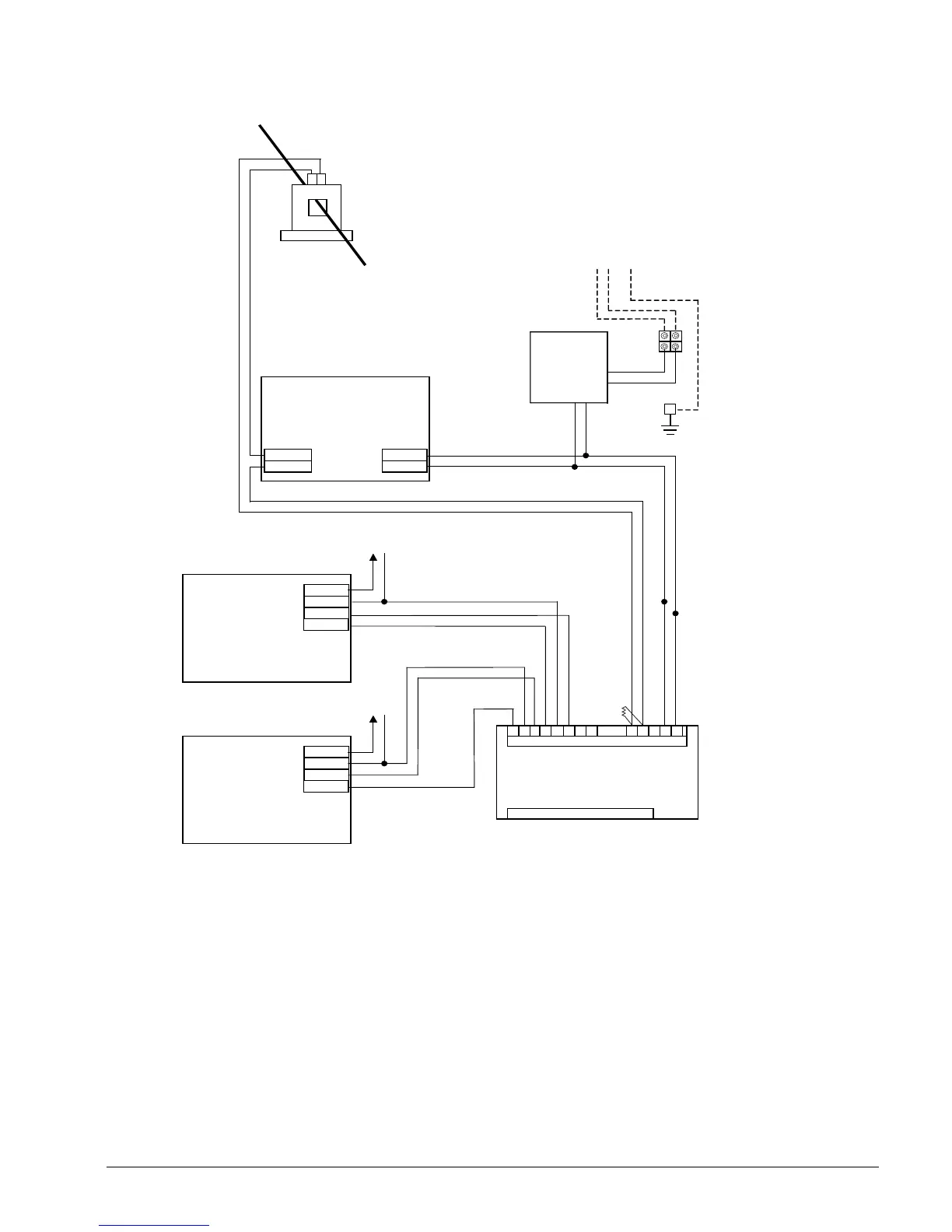

Figure 33. Hardwired Chiller’s Possible Hardware Requirements

Transformer

40 VA

24 VAC Secondary

Ground

Primary

Primary Power Supply

3

Hardwired Chiller’s

Remote I/O Module

4

10 VA

Low Voltage Terminals-Brown

High Voltage Terminals-Orange

11 10 2 1

SIG OUT

COM

24V PWR

SIG IN

0-10 VDC to 4-20 mA

Converter for Chilled Water

Temperature Reset

10 VDC

4-20 mA to

Chiller Setpoint

Reset AI

Signal Converter

2.5 VA

10 VDC

4-20 mA to Chiller

Demand Limit AI

SIG OUT

COM

24V PWR

SIG IN

0-10 VDC to 4-20 mA

Converter for Load Limiting

Signal Converter

2

2.5 VA

24

dc Power Supply

1

15 VA

24 VDC Out +

24 VDC Out -

24 VAC In G

24 VAC In H

Current Transducer Mounted on Chiller

1

(4-20 mA Output)

Range

0-300 Amps

0-800 Amps

0-2400 Amps

+ -

499

Ω

Res

Notes:

1. Current Transducer and 24 VDC Power Supply required if chiller does not output a %RLA signal (0-10 VDC or 4-20 mA) directly.

2. Signal Converter required if chiller does not accept 2-10 VDC signals at it’s analog inputs.

3. Power supply must provide electrical isolation between inputs and outputs.

4. McQuay remote I/O panel provides 40VA-24VAC transformer and is available with up to four remote I/O modules. See IM 783-

MicroTech II Remote I/O Panel Installation Manual for more information. Verify dimensions of the remote I/O panel for clearance

and follow appropriate electrical codes.

35 34 33 32 31 30

Loading...

Loading...