Page 8 IM 781-2

Applying the CSM

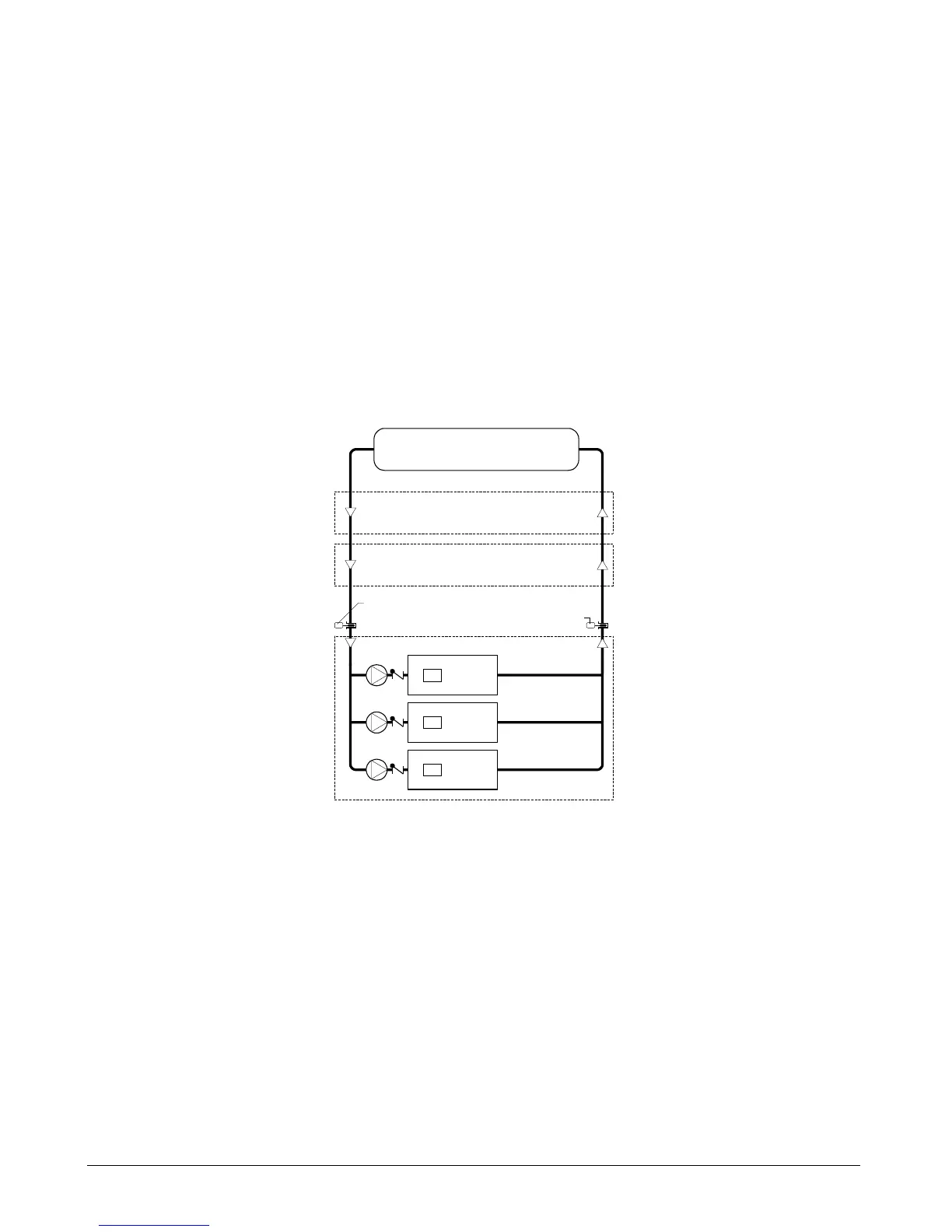

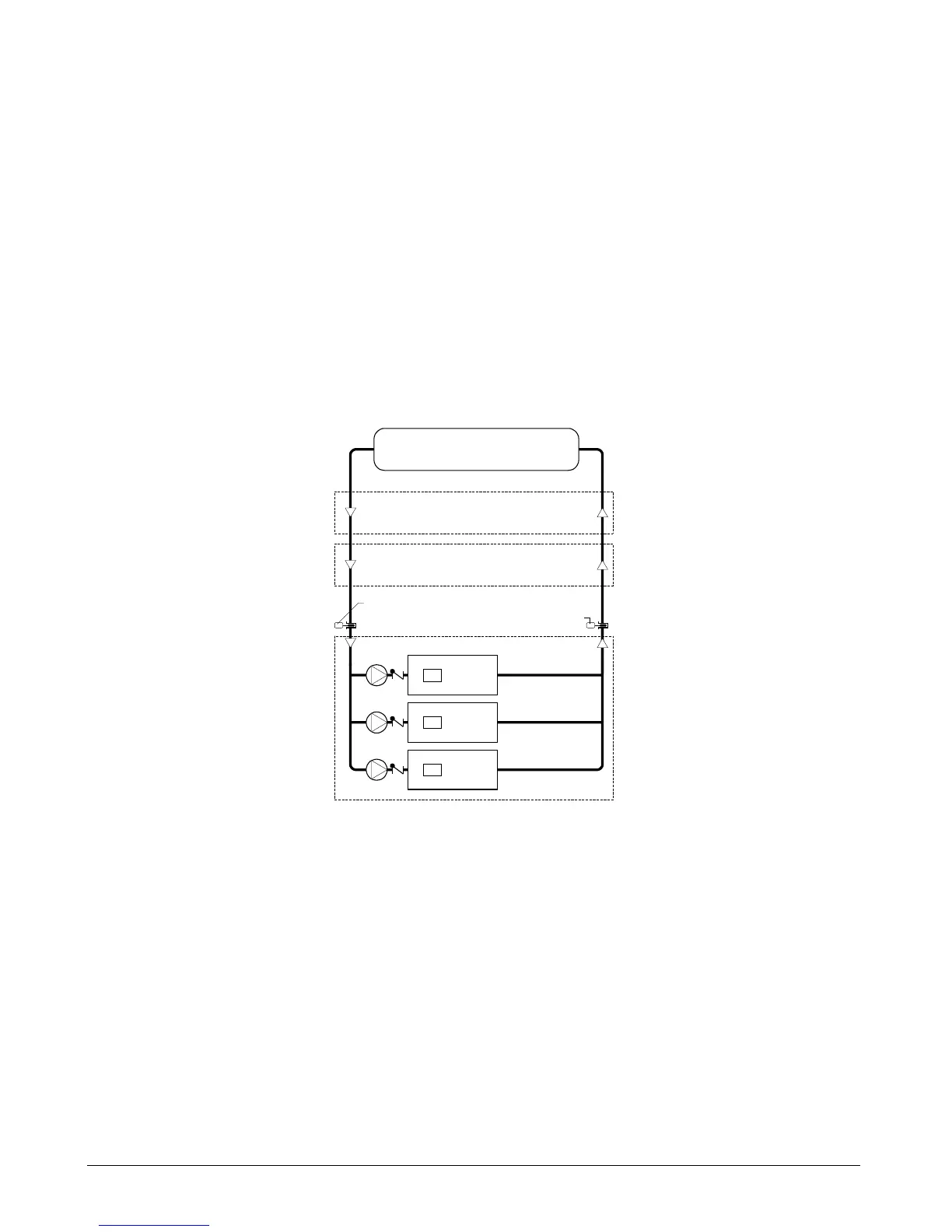

The CSM has been designed to control several common chiller plant configurations. Figure 2 shows a typical chilled water

system configuration. The following pages describe typical plant configurations that can be controller by the CSM and the

guidelines for applying the CSM in them. The chillers in these configurations can be all centrifugal, all reciprocating, all

screw, or a combination of centrifugal, reciprocating, or screw.

The CSM may be suitable for applications other than those shown. If your application does not match one of the listed

configurations, contact your McQuay sales representative for assistance.

Typical Chilled Water System

The typical chilled water system configuration is shown in Figure 2. The characteristics of this system consist of the

following: (1) a set of chillers, usually piped in parallel, (2) each chiller has its own primary chilled water pump, (3) the

system may or may not have a bypass line and valve that is controlled by a differential pressure controller, (4) the system

may have secondary pump(s) to distribute water to the cooling loads.

Figure 2. Typical Chilled Water System

Cooling Loads

Chiller #3

centrifugal

C

Chiller #2

centrifugal

C

Chiller #1

centrifugal

C

Chiller evaporator configuration

Loop bypass configuration

Return chilled water temperature

Supply chilled water temperature

Secondary pump/decoupler line configuration

a0093

Variations to the typical chiller system configuration can be controlled. Refer to Figure 3 through Figure 11. The options

described by inserting these figures into the dotted areas shown in Figure 2 above can also be controlled by the CSM.

Chiller Evaporator Configuration

In these systems (Figure 3 through Figure 6), the temperature of the water entering the loads will always be very close to

each chiller’s leaving evaporator water temperature setpoint. In Figure 6, all chillers share a common primary pump but

each chiller has an isolation valve.

Loading...

Loading...