20

90-10122R30

GB

goh167

1

2

a

c

b

oh

MAINTENANCE

omh3

FUSE REPLACEMENT

IMPORTANT: Always carry spare SFE 20 AMP fuses.

The electric starting circuit is protected from overload by an SFE 20 AMP fuse. If

the fuse is blown, the electric starter motor will not operate. Try to locate and

correct the cause of the overload. If the cause is not found, the fuse may blow

again.

1 Open the fuse holder and look at the silver colored band inside the fuse. If band

is broken, replace the fuse. Replace fuse with a new fuse with the same rating.

ohk7

CORROSION CONTROL ANODE

2

An anode (a) is installed on the bottom of the transom bracket assembly. Trim

tab (b) is also an anode on the 3-1/4 in. (83mm) diameter gear case. The 4-1/4

in. (108mm) diameter gear case has three anodes. One of the anodes is the

trim tab (b) and two anodes (c) are located on the side. An anode helps protect

the outboard against galvanic corrosion by sacrificing its metal to be slowly

eroded instead of the outboard metals.

Each anode requires periodic inspection especially in salt water which will

accelerate the erosion. To maintain this corrosion protection, always replace the

anode before it is completely eroded. Never paint or apply a protective coating on

the anode as this will reduce effectiveness of the anode.

goh82

2

4-53

1

N

N

ohl10

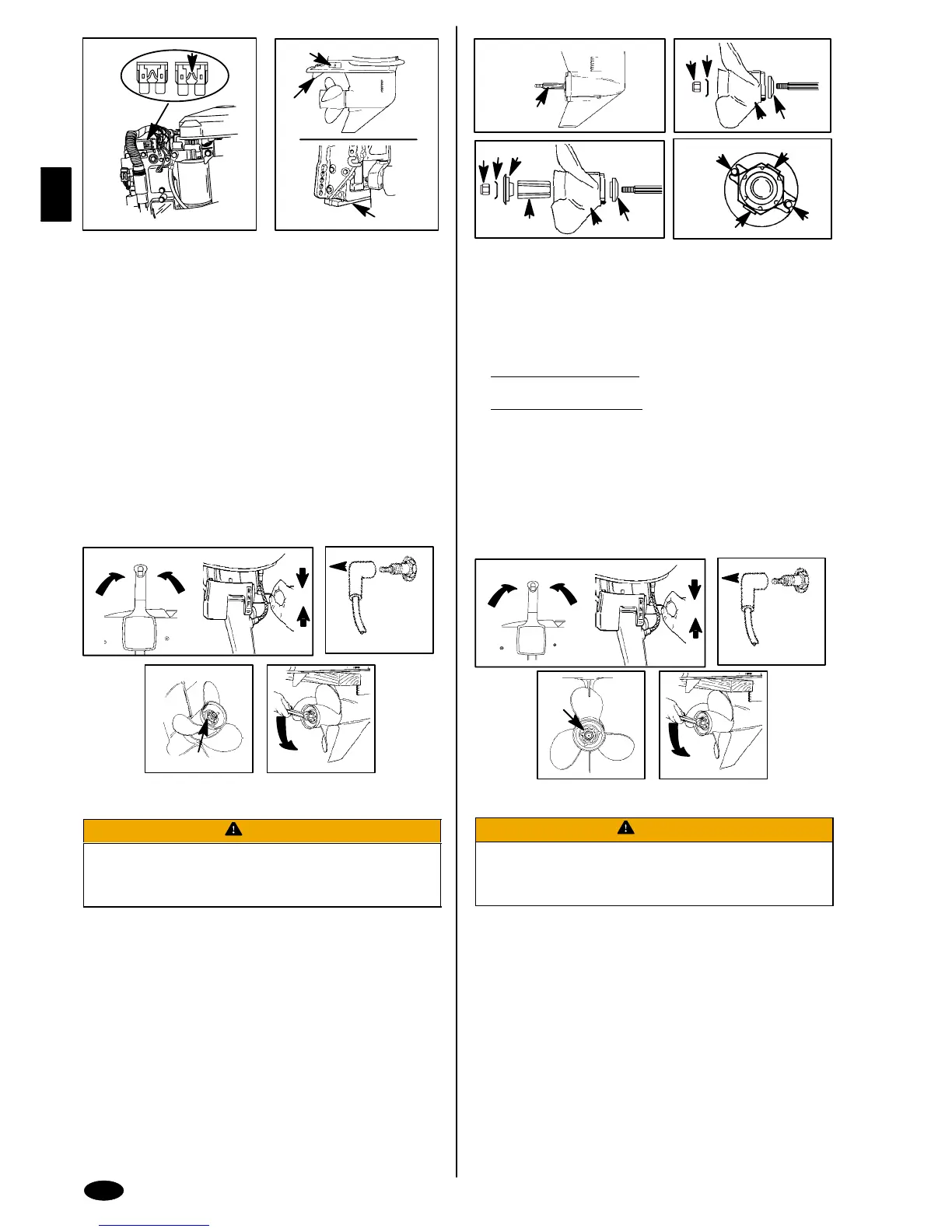

PROPELLER REPLACEMENT - 3-1/4 IN. (83MM)

DIAMETER GEAR CASE

WARNING

If the propeller shaft is rotated while the engine is in gear, there is the pos-

sibility that the engine will crank over and start. To prevent this type of

accidental engine starting and possible serious injury caused from being

struck by a rotating propeller, always shift outboard to neutral position

and remove spark plug leads when you are servicing the propeller.

1 Shift outboard to neutral (N) position.

2 Remove spark plug leads to prevent engine from starting.

3 Straighten the bent tabs on the propeller nut retainer.

4 Place a block of wood between gear case and propeller to hold propeller and

remove propeller nut.

5 Pull propeller straight off shaft. If propeller is seized to the shaft and cannot be

removed, have the propeller removed by an authorized dealer.

goh62

6

8 9-10

7

a

c

b

d

ac

b

de

f

a

a

b

b

ohl36h

PROPELLER REPLACEMENT - 4-1/4 IN. (108MM)

DIAMETER GEAR CASE

6 Coat the propeller shaft with Quicksilver or Precision Lubricants

Anti-Corrosion Grease or 2-4-C Marine Lubricant with Teflon.

IMPORTANT: To prevent the propeller hub from corroding and seizing to the

propeller shaft, especially in salt water, always apply a coat of the

recommended lubricant to the entire propeller shaft at the recommended

maintenance intervals and also each time the propeller is removed.

7 Flo-Torque I Drive Hub Propellers - Install forward thrust hub (a), propeller (b),

propeller nut retainer (c) and propeller nut (d) onto the shaft.

8 Flo-Torque II Drive Hub Propellers - Install forward thrust hub (a), propeller (b),

replaceable drive sleeve (c), rear thrust hub (d), propeller nut retainer (e) and

propeller nut (f) onto the shaft.

9 Place propeller nut retainer over pins (a). Place a block of wood between gear

case and propeller and tighten propeller nut to 55 lb. ft. (75 N·m), aligning flat

sides of the propeller nut with tabs on the propeller nut retainer.

10Secure propeller nut by bending tabs (b) up and against the flats on the

propeller nut.

11 Reinstall spark plug leads.

goh208

2

4-53

1

N

N

ohl12

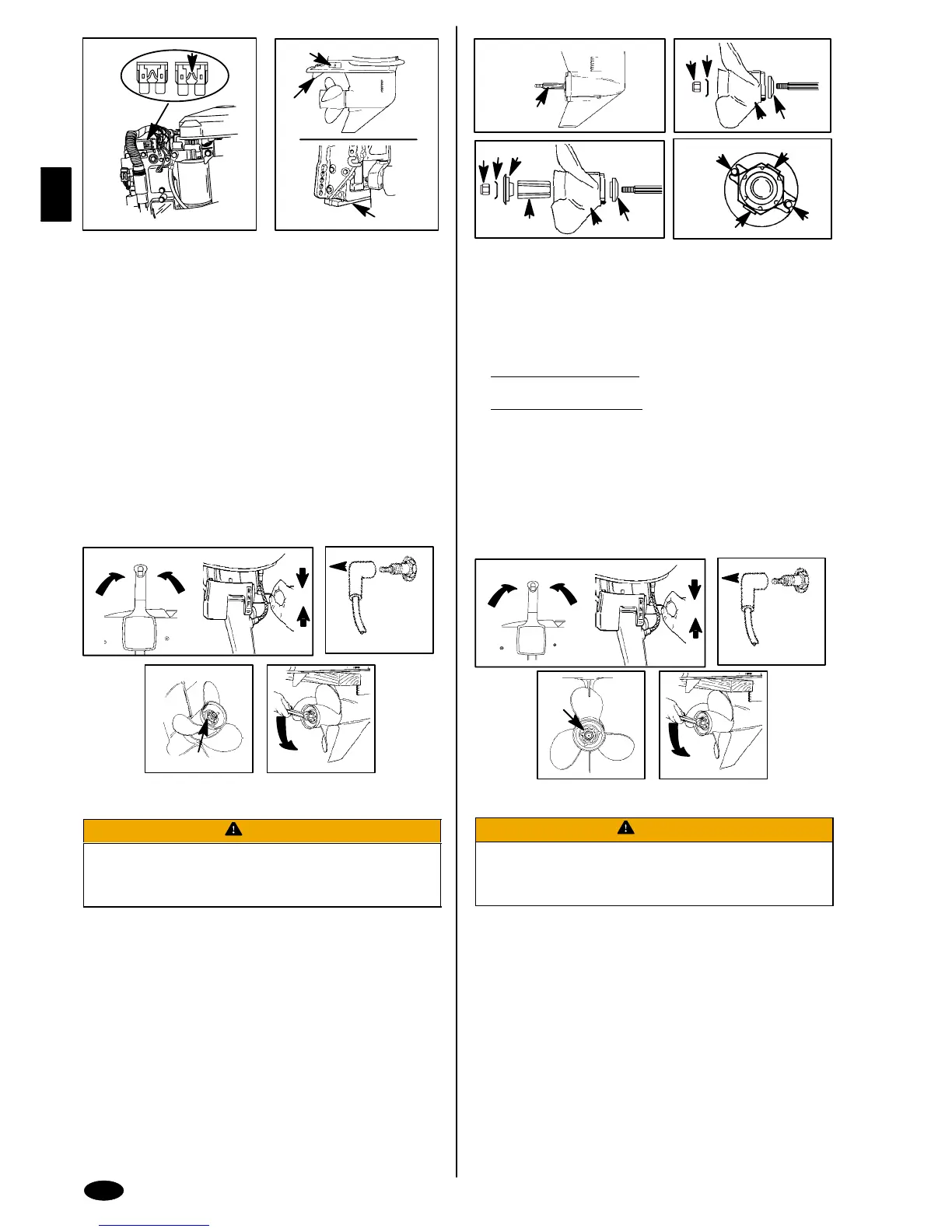

PROPELLER REPLACEMENT - 4-1/4 IN. (108MM)

DIAMETER GEAR CASE

WARNING

If the propeller shaft is rotated while the engine is in gear, there is the pos-

sibility that the engine will crank over and start. To prevent this type of

accidental engine starting and possible serious injury caused from being

struck by a rotating propeller, always shift outboard to neutral position

and remove spark plug leads when you are servicing the propeller.

1 Shift outboard to neutral (N) position.

2 Remove spark plug leads to prevent engine from starting.

3 Straighten the bent tabs on the propeller nut retainer.

4 Place a block of wood between gear case and propeller to hold propeller and

remove propeller nut.

5 Pull propeller straight off shaft. If propeller is seized to the shaft and cannot be

removed, have the propeller removed by an authorized dealer.

Loading...

Loading...