21

90-10122R30

GB

g

6

7

9-10

8

a

cb

d

e

f

a

c

b

d

e

f

oh

MAINTENANCE

ohl34

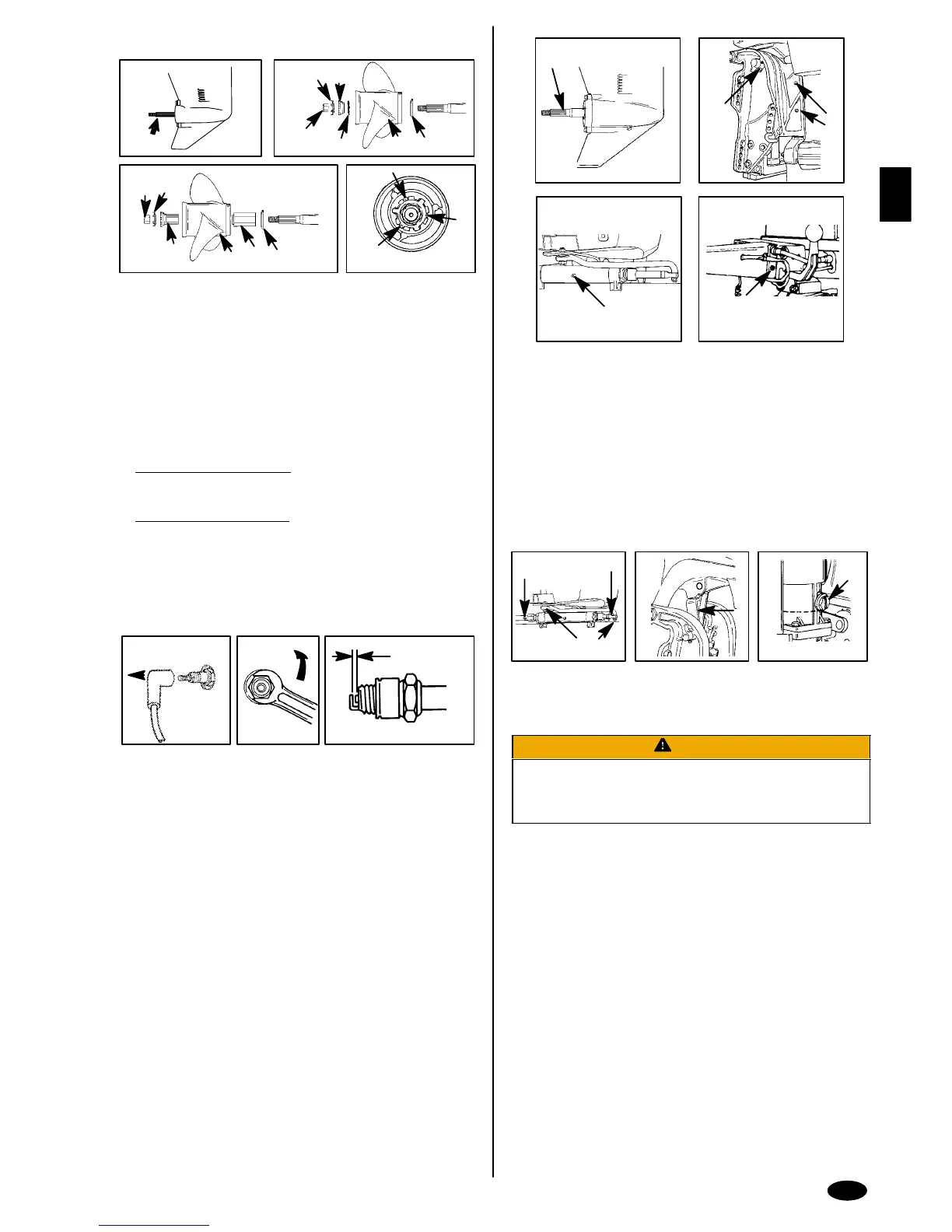

PROPELLER REPLACEMENT - FOR 4-1/4 IN. (108MM)

DIAMETER GEAR CASE

6

Coat the propeller shaft with Quicksilver or Mercury Precision Lubricants

Anti-Corrosion Grease or 2-4-C Marine Lubricant with Teflon.

IMPORTANT: To prevent the propeller hub from corroding and seizing to the

propeller shaft, especially in salt water, always apply a coat of the

recommended lubricant to the entire propeller shaft at the recommended

maintenance intervals and also each time the propeller is removed.

7 Flo-Torque I Drive Hub Propellers - Install thrust washer (a), propeller (b),

continuity washer (c), thrust hub (d), propeller nut retainer (e), and propeller

nut (f) onto the shaft.

8 Flo-Torque II Drive Hub Propellers - Install forward thrust hub (a), replaceable

drive sleeve (b), propeller (c), thrust hub (d), propeller nut retainer (e) and

propeller nut (f) onto the shaft.

9 Place a block of wood between gear case and propeller and torque propeller

nut to 55 lb. ft. (75 N·m).

10Secure propeller nut by bending three of the tabs into the thrust hub grooves.

goh14

1

2

3

ohm6

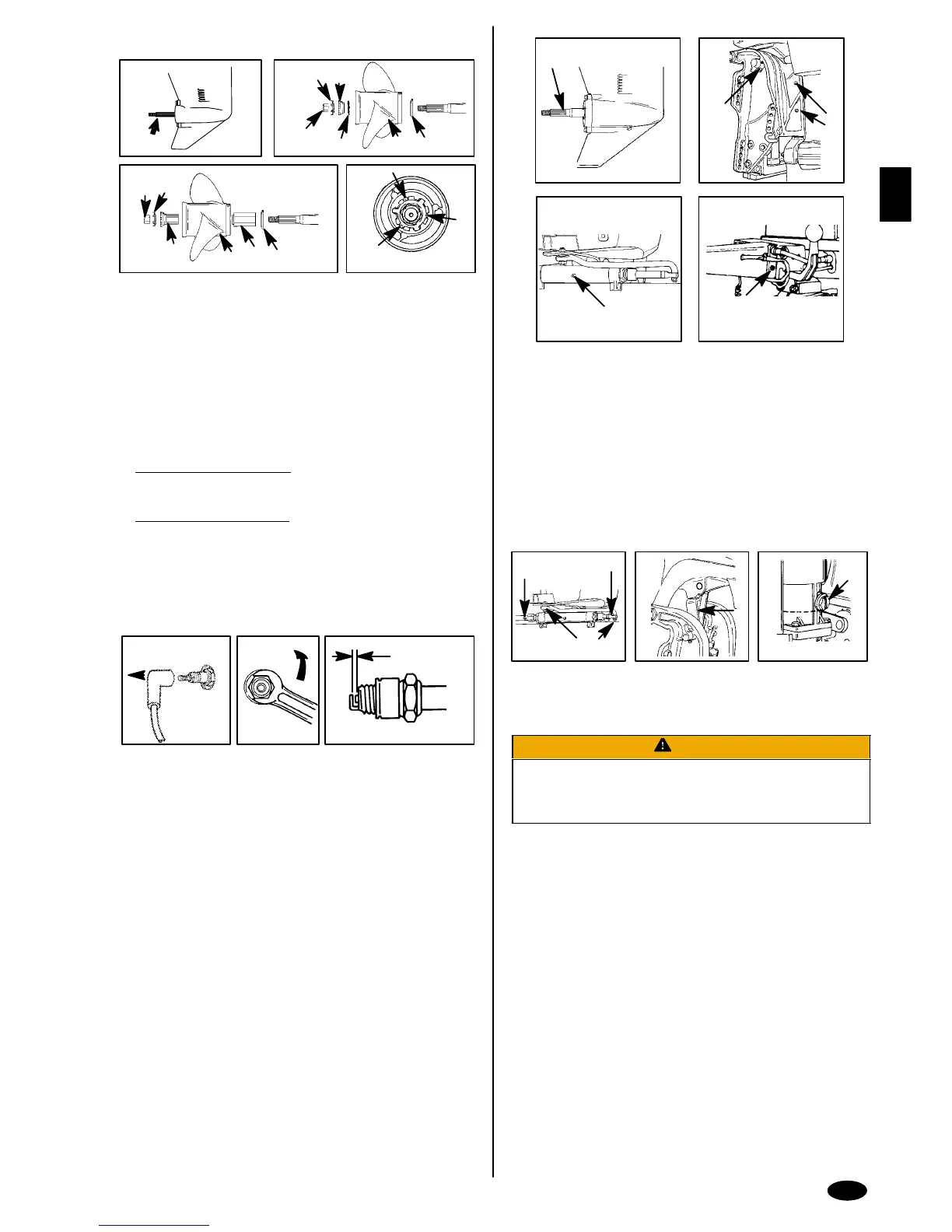

SPARK PLUG INSPECTION

Inspect spark plugs at the recommended intervals

1 Remove the spark plug leads by twisting the rubber boots slightly and pull off.

2 Remove the spark plugs to inspect and clean. Replace spark plug if electrode

is worn or the insulator is rough, cracked, broken, blistered or fouled.

3 Set the spark plug gap. See Specification Chart in General Information Section.

4 Before reinstalling spark plugs, clean away dirt on the spark plug seats. Install

plugs finger tight, and tighten 1/4 turn or torque to 20 lb. ft. (27 N·m).

goh84

1

4

5

2

3

oho62

LUBRICATION POINTS

Lubricate Point 1 with Quicksilver or Mercury Precision Lubricants

Anti-Corrosion Grease or 2-4-C Marine Lubricant with Teflon

1 Propeller Shaft - Refer to Propeller Replacement for removal and installation

of the propeller. Coat the entire propeller shaft with lubricant to prevent the

propeller hub from corroding and seizing to the shaft.

Lubricate Points 2 thru 6 with Quicksilver or Mercury Precision Lubricants

2-4-C Marine Lubricant with Teflon or Special Lubricant 101.

2 Swivel Bracket - Lubricate through fitting.

3 Tilt Support Lever - Lubricate through fitting.

4 Tilt Tube - Lubricate through fitting.

5 Tiller Handle - Lubricate through fitting.

goh76

89

6-b

7

6-a

oho43

LUBRICATION POINTS (CONTINUED)

6

Steering Cable Grease Fitting (IF Equipped) - Rotate steering wheel to fully

retract the steering cable end (a) into the outboard tilt tube. Lubricate through

fitting (b).

WARNING

The end of the steering cable must be fully retracted into the outboard tilt

tube before adding lubricant. Adding lubricant to steering cable when ful-

ly extended could cause steering cable to become hydraulically locked.

An hydraulically locked steering cable will cause loss of steering control,

possibly resulting in serious injury or death.

Lubricate Points 7 With Light Weight Oil.

7 Steering Link Rod Pivot Points - Lubricate points.

ohp3

CHECKING POWER TRIM FLUID

8

Tilt outboard to the full up position and engage the tilt support lock.

9 Remove fill cap and check fluid level. The fluid level should be even with the

bottom of the fill hole. Add Quicksilver or Mercury Precision Lubricants Power

Trim & Steering Fluid. If not available, use automotive (ATF) automatic

transmission fluid.

Loading...

Loading...