Section 5 - Maintenance

Page 26 90-899883210 APRIL 2008

Owner and Operator Responsibilities

This manual only covers the Total Command system, and does not address the maintenance of the

engines, transmissions, or other vessel components or systems. For information covering the operation

and maintenance of your engine and transmission, refer to the appropriate engine owners and operators

manual. For all other information, refer to your vessel operations manual.

It is the operator's responsibility to ensure the performance of all safety checks, to ensure that all lubrication

and maintenance instructions are complied with for safe operation, and to return the vessel to a Mercury

MerCruiser dealer or Cummins MerCruiser Diesel authorized repair facility for a periodic checkup. If you

have any questions about how to perform these checks, consult your dealer or distributor for additional

information. While many owners are capable of performing these checks, it is best to have all checks and

maintenance performed by a trained service technician.

Normal maintenance, service, and replacement parts are the responsibility of the owner or operator and

as such, are not considered defects in workmanship or material within the terms of the warranty. Individual

operating habits and usage contribute to the need for maintenance service.

Proper maintenance and care of your Total Command system will ensure optimum performance and

dependability, and will keep your overall operating expenses at a minimum. See your Mercury MerCruiser

dealer or your Cummins MerCruiser Diesel authorized repair facility for parts and service.

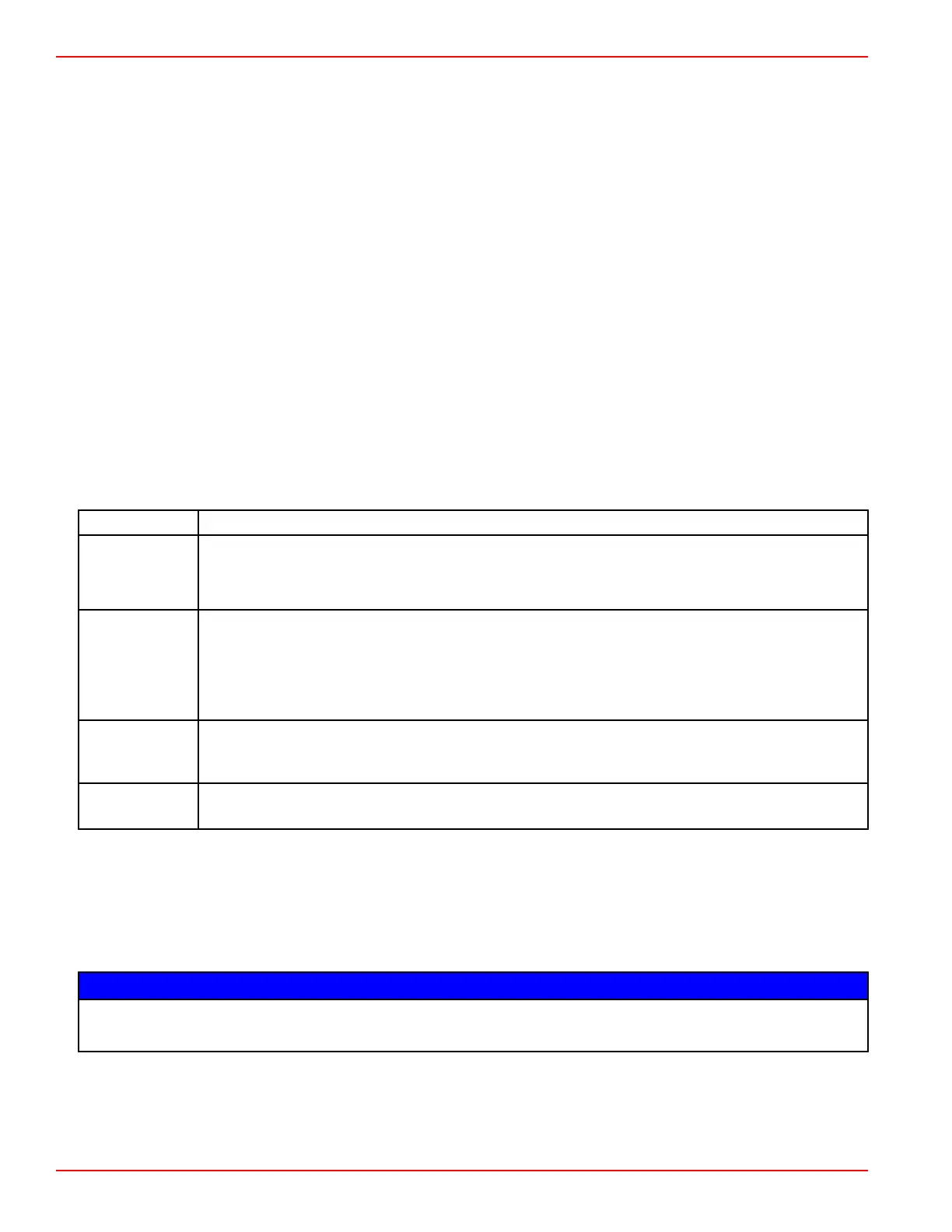

Maintenance Schedule

Maintenance

Task Interval Maintenance to Be Performed

Annually or as

needed;

whenever vessel

is out of the water

• Check for and remove fish line and other obstructions from the propellors and tunnels.

• Clean and paint thruster leg with anti‑fouling paint

Every 100 hours

or annually

(whichever occurs

first)

• Conduct visual checks of the entire system for corrosion, abrasion, or breakage

• Check power and control cables for abrasion and corrosion

• Clean and tighten all the connections

• Check the state of the batteries (Best performed by a trained technician)

• Cover the drive leg seals with silicone grease (Best performed by a trained technician)

Every 200 hours

or 2 years

• Check for oil leakage on the thruster drive leg

• Remove the thruster propeller(s) to check for fishing line or other debris on the propeller shaft (Best

performed by a trained technician)

Every 300 hours

or 3 years

• Check relay contacts for wear or damage (Best performed by a trained technician)

• Check motor brushes for excessive wear or damage (Best performed by a trained technician)

System Maintenance

Electrical Tests and Measurements

A constant drop in voltage is the most frequent cause of rapid deterioration of the relays and motor brushes.

Check the condition of the batteries, connections, and power cables as specified in the Maintenance

Schedule. These checks are best performed by trained technicians with special equipment.

NOTICE

Operating the thrusters out of water for any amount of time can damage the motors or seals. Perform

tests only with the thrusters completely submerged in water to prevent damage.

Conduct all operational tests under normal operating conditions, with the vessel in the water, with fully

charged batteries, with the engines running and the charging system on. Do not operate the system with

the vessel out of the water.

Loading...

Loading...