INSTALLATION

Page 1D-4 90-888438 JUNE 2002

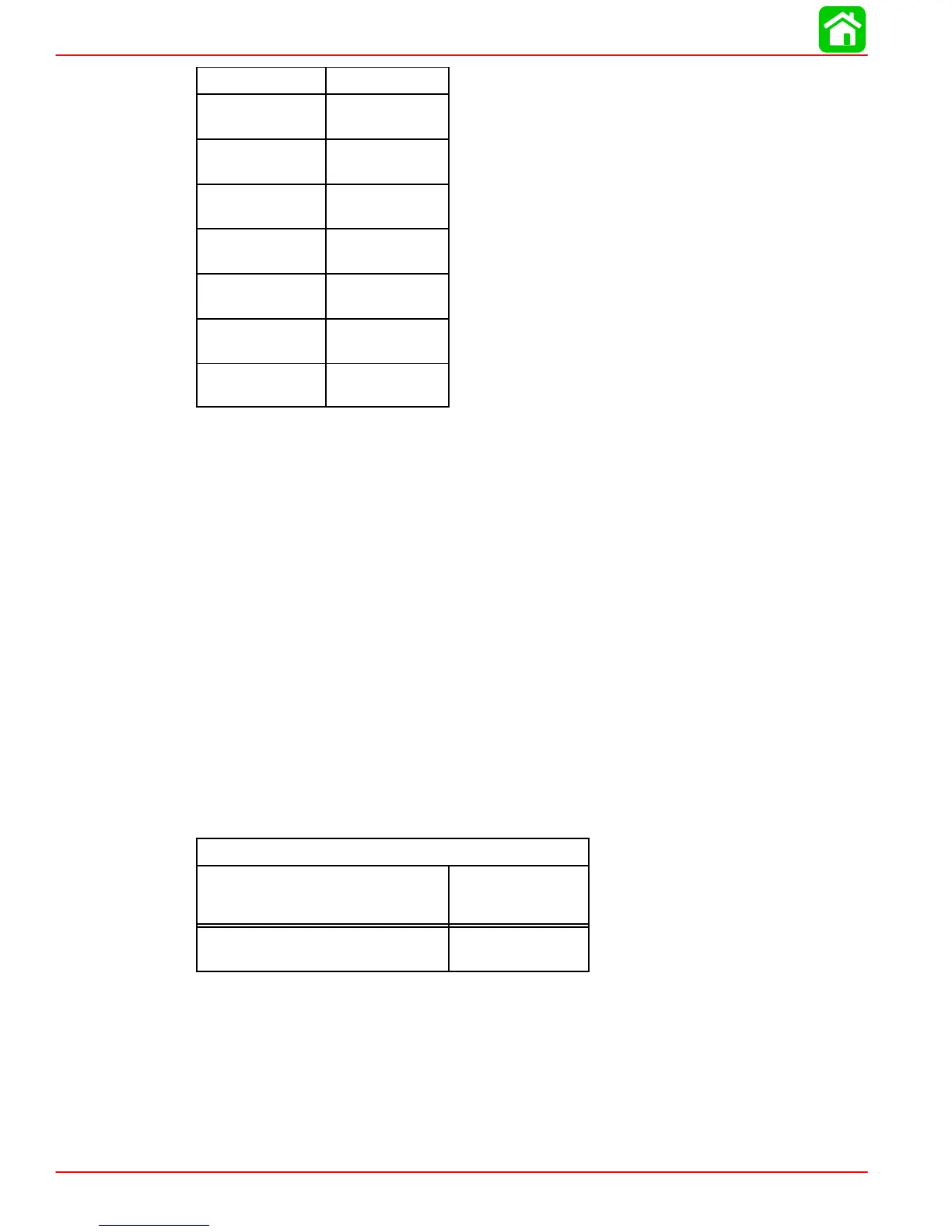

Cable Length Cable Gauge

Up to 3-1/2 ft.

(1.1 m)

4 (25mm

2

)

3-1/2 - 6 ft.

(1.1-1.8 m)

2 (35mm

2

)

6 - 7-1/2 ft.

(1.8-2.3 m)

1 (50mm

2

)

7-1/2 - 9-1/2 ft.

(2.3-2.9 m)

0 (50mm

2

)

9-1/2 - 12 ft.

(2.9-3.7 m)

00 (70mm

2

)

12 - 15 ft. (3.7-

4.6 m)

000 (95mm

2

)

15 - 19 ft. (4.6

- 5.8 m)

0000 (120mm

2

)

Boat Construction

IMPORTANT: All applicable U.S. Coast Guard regulations for INBOARD engines must

be complied with when constructing engine compartment.

Care must be exercised in the design and construction of the engine compartment. Seams

must be located so that any rain water or splash, which may leak through the seams, is di-

rected away from the engine and its air intake. Also, the passenger compartment drainage

system should not be routed directly to the engine compartment. Water that runs on or is

splashed in the air intake may enter the engine and cause serious damage to internal

engine parts.

IMPORTANT: Mercury Marine will not honor any warranty claim for engine damage

as a result of water entry.

Engine Compartment Ventilation

Engine compartment must be designed to provide a sufficient volume of air for engine

breathing and also must vent off any fumes in engine compartment in accordance with

industry standards (ABYC, NMMA, etc.), federal standards and U.S. Coast Guard regula-

tions for inboard engines. Pressure differential (outside engine compartment versus inside

engine compartment) should not exceed 2 in. (51mm) of water (measured with a manome-

ter) at maximum air flow rate.

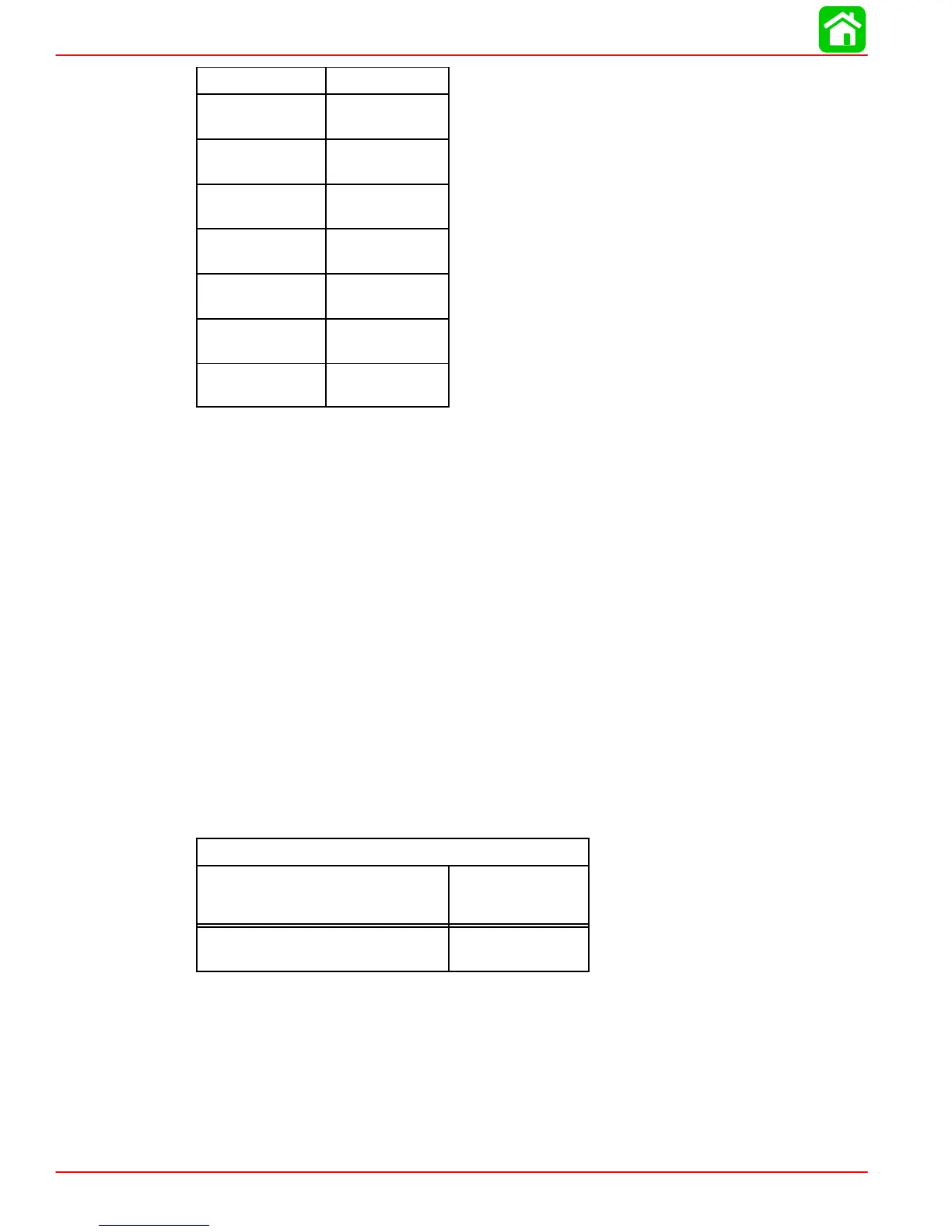

Engine Compartment Specifications

Engine Air Requirements at Wide

Open Throttle

Physical Engine

Volume*

552 ft.

3

/min.

(0.260 m

3

/sec.)

1.41 ft.

3

(40.4 L)

* Physical engine volume is used in flotation calculations and is representative of the amount

of flotation the engine provides.

For serviceability, it is recommended that an additional 6 inches minimum (152 mm) (per

side) of clearance be allowed between powerhead and engine compartment walls.

Loading...

Loading...