Replacing the Engine Coolant in the Closed‑Cooling System

Draining the Closed‑Cooling System

NOTICE

Discharge of oil, coolant, or other engine/drive fluids into the environment is restricted by law. Use caution not to spill oil,

coolant, or other fluids into the environment when using or servicing your boat. Be aware of the local restrictions governing

the disposal or recycling of waste, and contain and dispose of fluids as required.

NOTE: For instructions on draining the seawater section, refer to

Flushing and Draining the Seawater System

in this section.

IMPORTANT: Observe the following points:

• Ensure that the engine is as level as possible to promote complete draining of the cooling system.

• The closed‑cooling section must be filled year‑round with the required coolant. If the engine will be exposed to freezing

temperatures, ensure that the closed‑cooling section is filled with a solution of ethylene glycol antifreeze and water properly

mixed to protect the engine to the lowest temperature to which it will be exposed.

• Do not use propylene glycol antifreeze in the closed‑cooling section of the engine.

!

CAUTION

A sudden loss of pressure can cause hot coolant to boil and discharge violently, resulting in serious injury from burns. Allow

the engine to cool down before removing the coolant pressure cap.

1. Allow the engine to cool.

2. Remove the pressure cap from the expansion tank coolant reservoir.

3. Loosen the closed cooling heat exchanger drain screw approximately two turns, and allow the contents to drain into an

appropriate container.

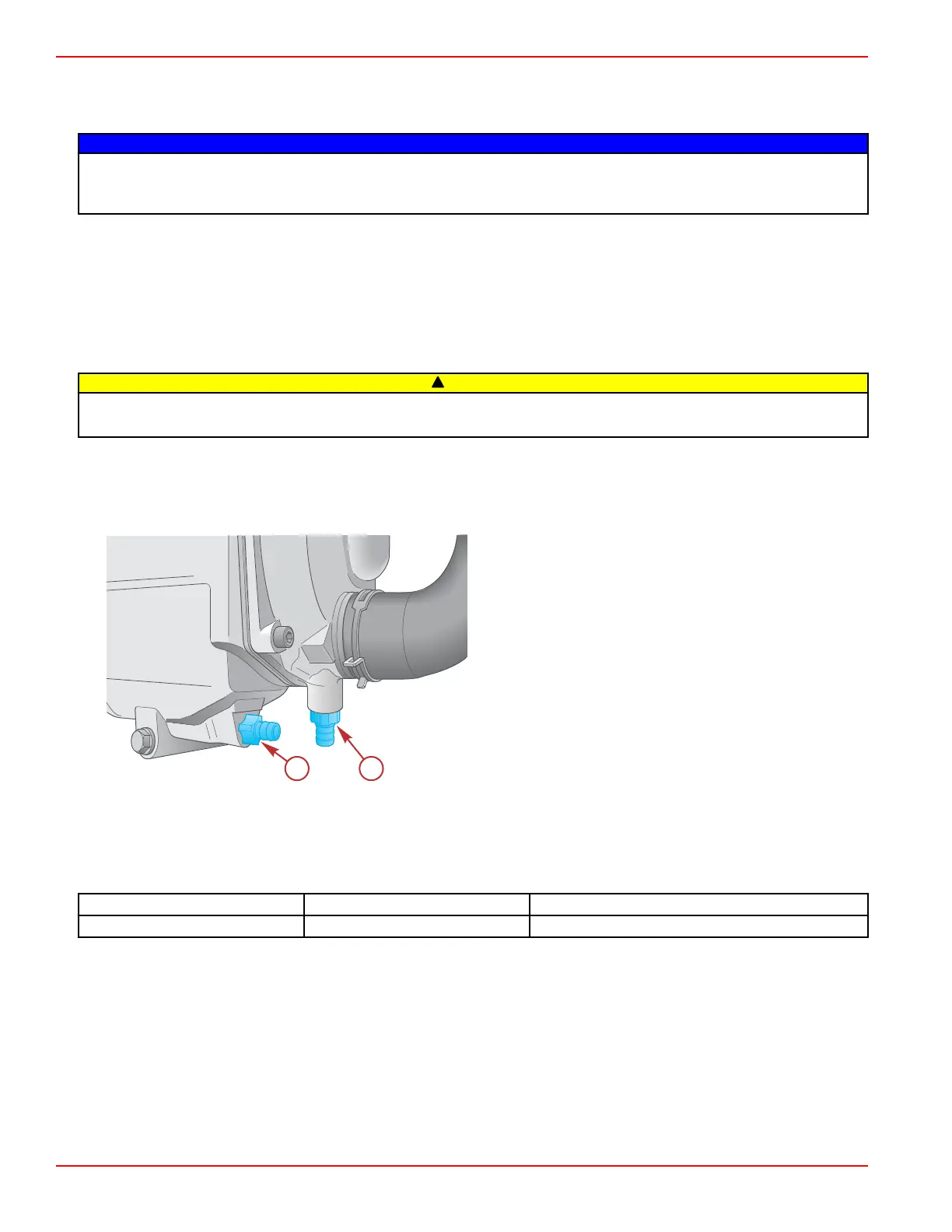

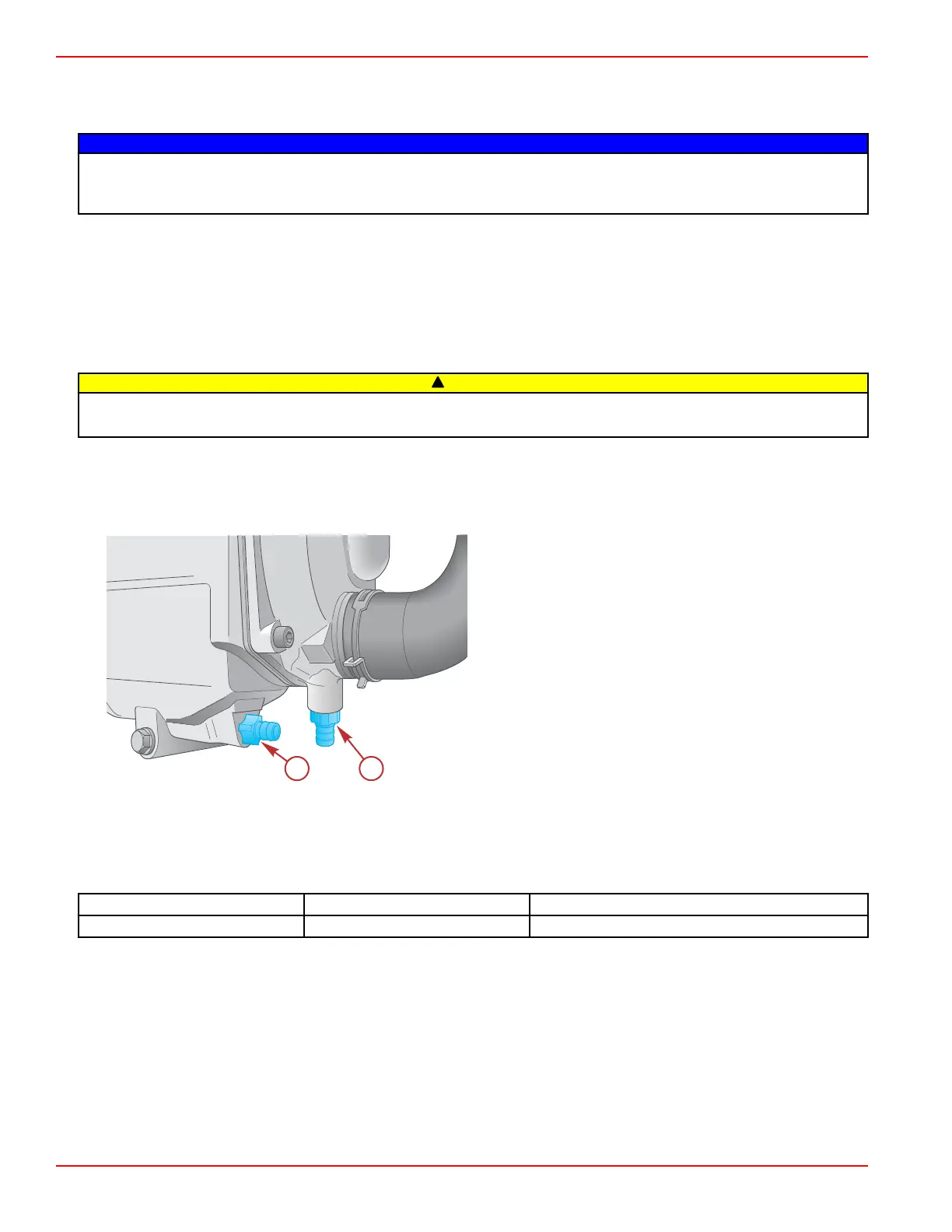

a - Closed‑cooling system drain screw

b - Seawater system drain screw

4. If required, clean the closed‑cooling system. See your Mercury Diesel authorized repair facility.

5.

Fill the system with the specified coolant. Refer to Filling the Closed‑Cooling System.

Filling the Closed‑Cooling System

IMPORTANT: Use only the specified coolant.

Description

Capacity Part Number

Extended Life Antifreeze/Coolant 9.0 Liter (9.5 US qt) 92‑877770K1

1. Verify that the closed‑cooling heat exchanger drain screw is tight.

Section 4 - Maintenance

Page 42 90-8M0133568 eng JUNE 2017

Loading...

Loading...