Loading...

Loading...

Do you have a question about the Metabo HC 260 C and is the answer not in the manual?

| Planing Width | 260 mm |

|---|---|

| Max. Planing Depth | 3 mm |

| Max. Thicknessing Height | 160 mm |

| Feed Rate | 5 m/min |

| Motor Power | 2.2 kW |

| Chip removal thickness planing | 3 mm |

| Chip removal thickness thicknessing | 3 mm |

| Table thicknessing table | 400 x 260 mm |

| Passage height/width | 160 mm / 260 mm |

| Planing shaft diameter | 63 mm |

| Number of blades | 2 |

| Planing table | 260 mm |

| Planing shaft speed | 6, 500 rpm |

Defines the intended purpose and limitations of the machine.

Provides fundamental safety measures for operating power tools.

Details critical risks like electric shock, cutting, and kickback hazards.

Explains how to start, stop, and monitor the machine's operation.

Describes safety mechanisms preventing accidental restarts and motor damage.

Details setting infeed and thicknesser bed heights for planing.

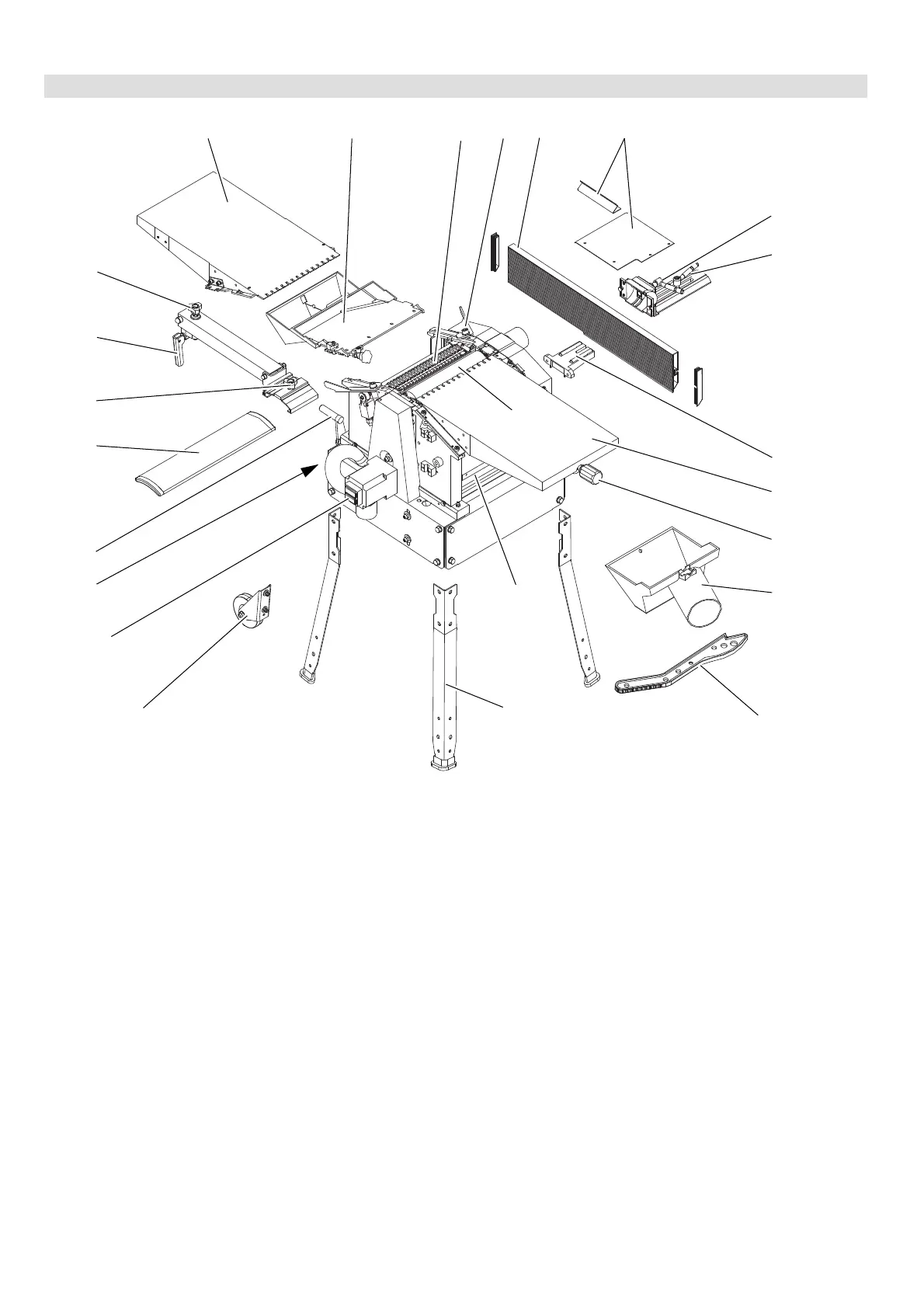

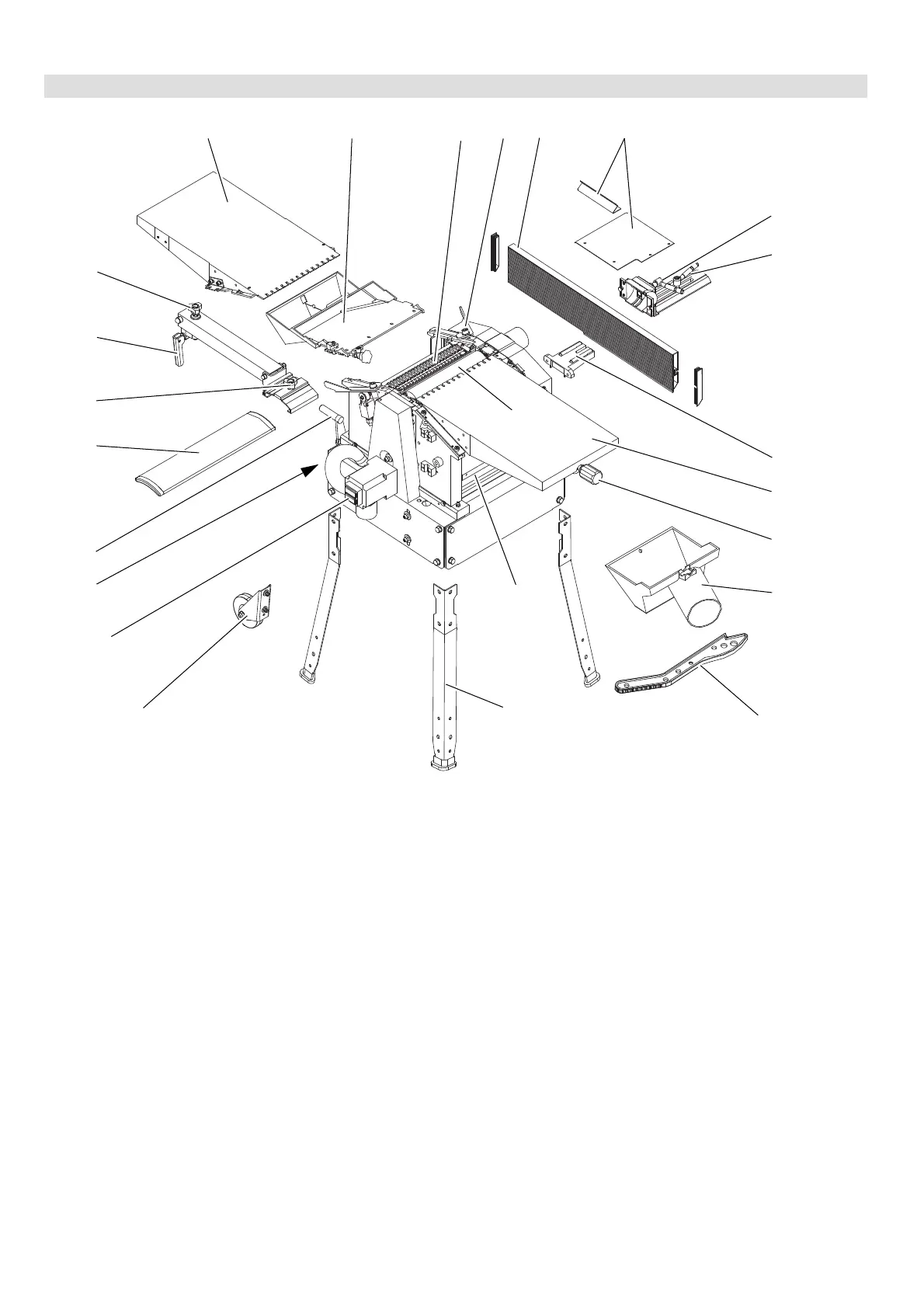

Lists the tools needed for assembling the machine.

Guides on removing protective materials before assembly.

Instructions for attaching the machine's legs.

Steps for mounting the infeed and outfeed tables.

Procedure for installing the chip chute.

Steps for attaching and adjusting the jointer fence.

Guidance on safely connecting the machine to the power source.

Explains how to set up and operate the machine for surface planing.

Detailed steps for planing surfaces and edge jointing wood.

Explains how to set up and operate for thickness planing.

Detailed steps for planing wood to a specific thickness.

Outlines essential safety steps before performing any maintenance.

Step-by-step guide for changing the planer knives.

Instructions for maintaining the feed mechanism.

How to check and adjust the drive belt tension.

Procedures for cleaning various machine components.

Guidance on safely moving the machine.

Recommendations for storing the machine securely.

A comprehensive checklist for regular maintenance tasks.

Initial steps to take before diagnosing faults.

Troubleshooting steps for when the motor does not run.

Diagnosing and resolving common performance problems like blunt knives or slipping belts.

Addressing issues like rough or cracked planed surfaces.

Troubleshooting problems related to feed rate and workpiece jamming.