Powered by TCPDF (www.tcpdf.org)

12 MUW216743-2

3.4. DOS Venting

Note: Instruments are NOT to be processed during

DOS venting.

The dispensing system for liquid chemical agents can only

dispense reliably if the system has been purged of air.

The DOS system must be vented:

• if the dispensing system is being used for the rst time

• if the liquid cleaning agent container was not relled or

replaced in time and the DOS system was sucked dry

(giving F518 or F519).

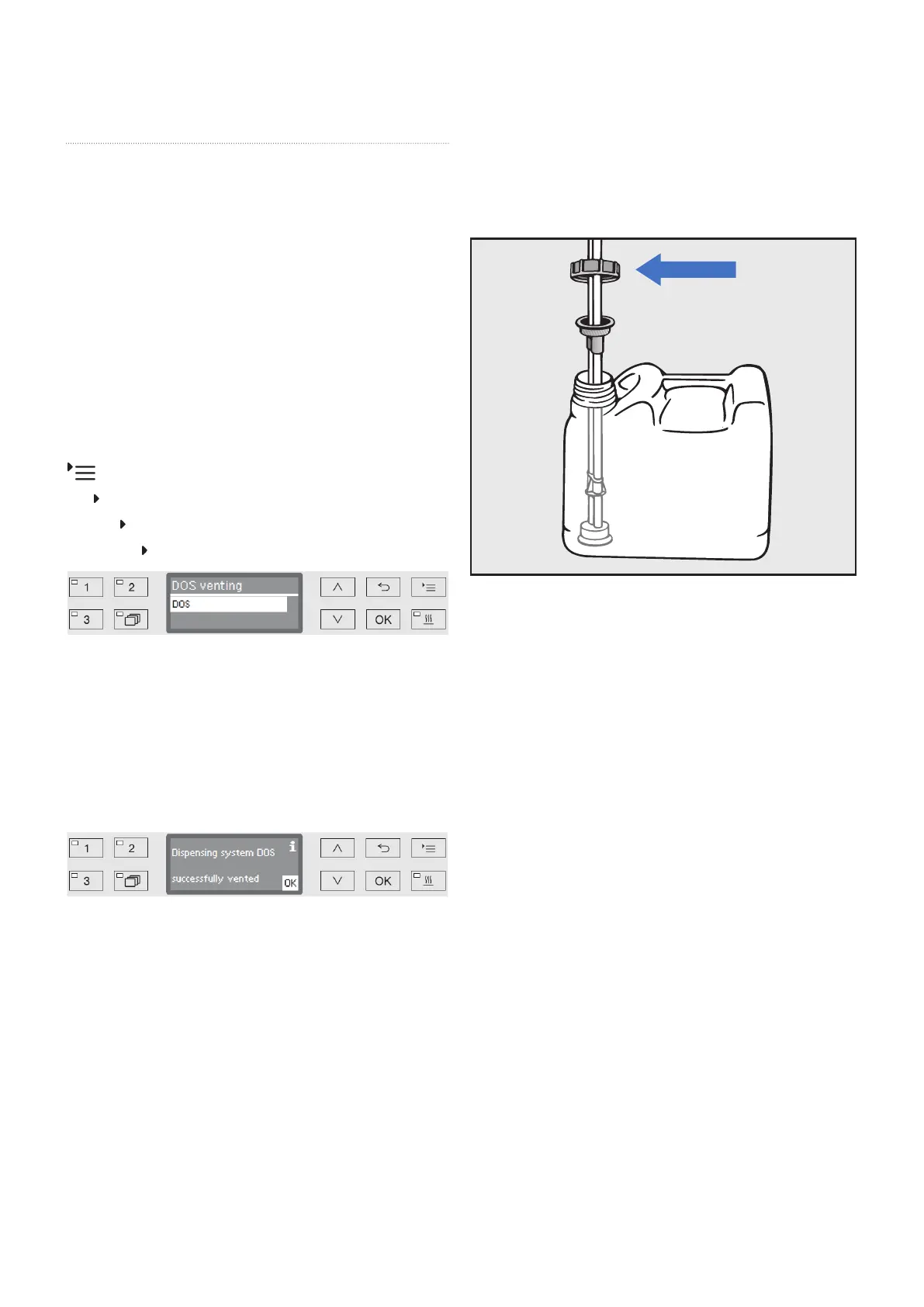

Before venting, ensure that the liquid chemical agent

container is suciently full and the siphons are securely

screwed to the containers. Push the suction tub/oat down

towards the bottom of the container. Only one DOS system

can be vented at a time.

Open the menu as follows:

button

Settings

DOS venting

DOS...(name of dispensing system)

Automatic venting will start when the dispensing system is

selected. Once started, the automatic venting process can no

longer be cancelled.

Select a dispensing system using the UP and DOWN buttons

(∧ ∨).

Press OK to start the venting process.

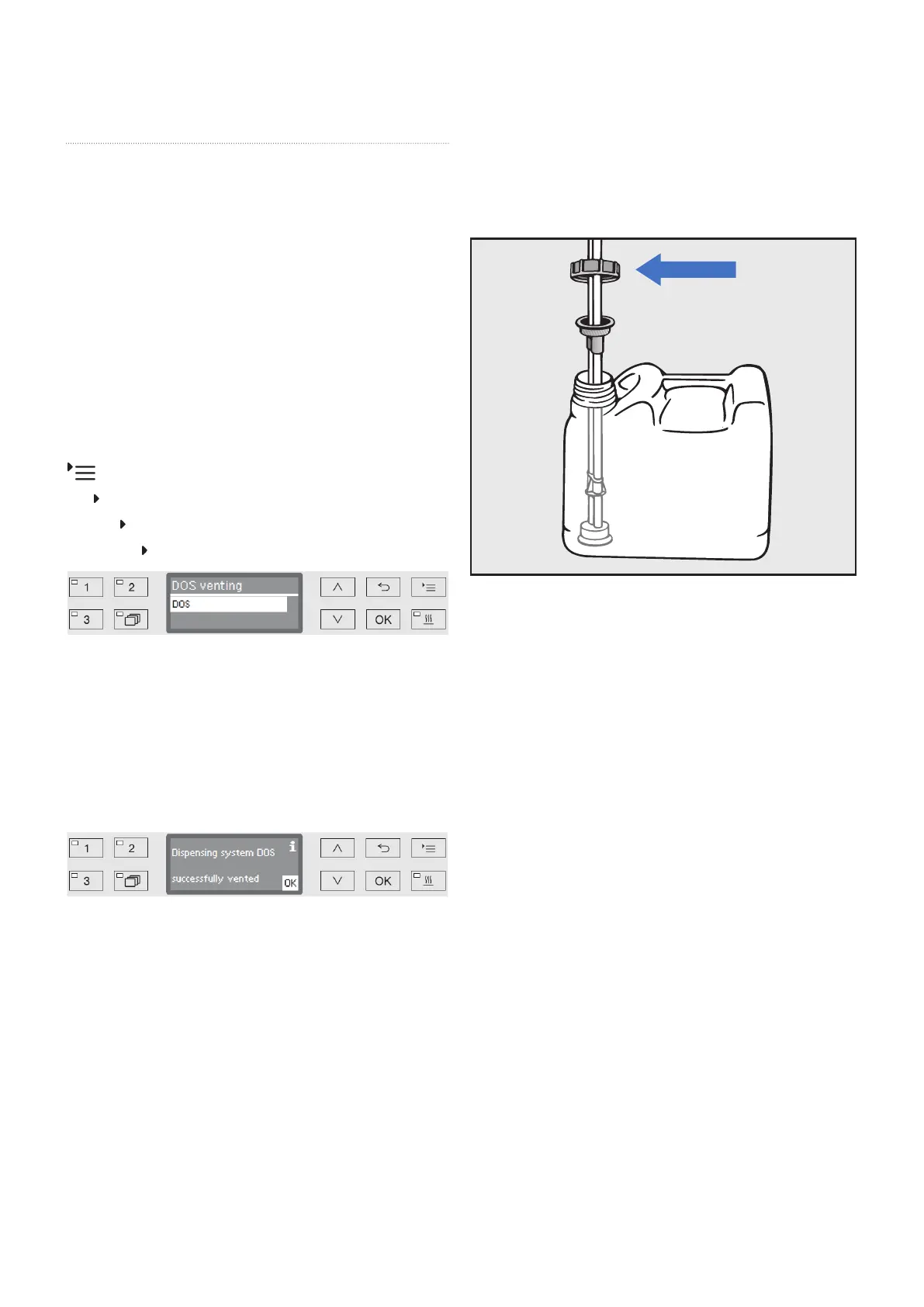

Automatic venting is successfully completed when the

following message appears in the display:

If the DOS3 system is vented, it is important to run at least

one rinse cycle, otherwise foaming will occur.

Detergent dispensed via dosing system

DOS 1 - Marked blue

Liquid detergent is dispensed from a 5 litre container via

the dosing system (DOS 1). The cap or lines on the tubing

are marked in blue. The 5 litre container is connected to the

machine by screwing on the blue marked suction tube.

Once tted ensure the tube is pushed to the bottom of the

container. When the container is nearly empty the screen

will display ‘DOS rell’ and it is time to replace it with a new

container to the blue suction tube.

If the chemical is renewed immediately there is no need

to vent, but if delayed for more than one cycle venting

becomes necessary.

Place the container on the oor next to the machine or in an

adjacent cupboard. Make sure that the dispensing hose is

not kinked or trapped.

Vent the dispensing system as necessary.

Adding and dispensing chemical agents

49

Neutralising agent

For certain programmes, neutralising agent is dispensed in the interim

rinse phase after washing, to help prevent discolouration and

corrosion spots on the instruments (especially around jointed areas).

Neutralising agent (pH setting: acidic) neutralises any residues of

alkaline cleaning agents on the surface of the load.

Neutralising agent is dispensed automatically in the

Interim rinse

phase after the main wash (see Programme charts). The reservoir

must be filled and the dispensing system vented for this to occur.

Place the neutralising agent container (red marking) on the open

cabinet door or on a surface which is robust and easy to clean.

Unscrew and remove the siphon. Place the siphon on the open

cabinet door.

Replace the empty container with a full one.

Push the siphon into the opening of the container and screw it back

on tightly. Observe the colour coding.

Wipe up any spilled process chemical thoroughly.

Place the container on the floor next to the machine or in an

adjacent cupboard. Make sure that the dispensing hose is not

kinked or trapped.

Vent the dispensing system as necessary (see "Settings / Venting

DOS").

Check consumption regularly by checking the fill levels in the supply

containers and replace containers in good time to avoid the

dispensing system being sucked completely dry.

Refilling

neutralising agent

Checking

consumption

Loading...

Loading...