Powered by TCPDF (www.tcpdf.org)

16 MUW216743-2

5.1. Routine Checks

Before the start of each working day the user must carry

out a number of routine checks including any Daily/Weekly

Testing (Refer to Appendix 5).

The following need to be inspected:

• All lters in the wash cabinet

• The spray arms in the machine, and baskets

• The wash cabinet and the door seal

• The dispensing systems.

Cleaning the lters in the wash cabinet

The lters in the oor of the wash cabinet prevent coarse

soiling from coming into contact with the circulation system.

Filters can become blocked by soiling, so they need to be

checked every day and cleaned as necessary

.

- CAUTION

This machine must have all lters in place

before being used.

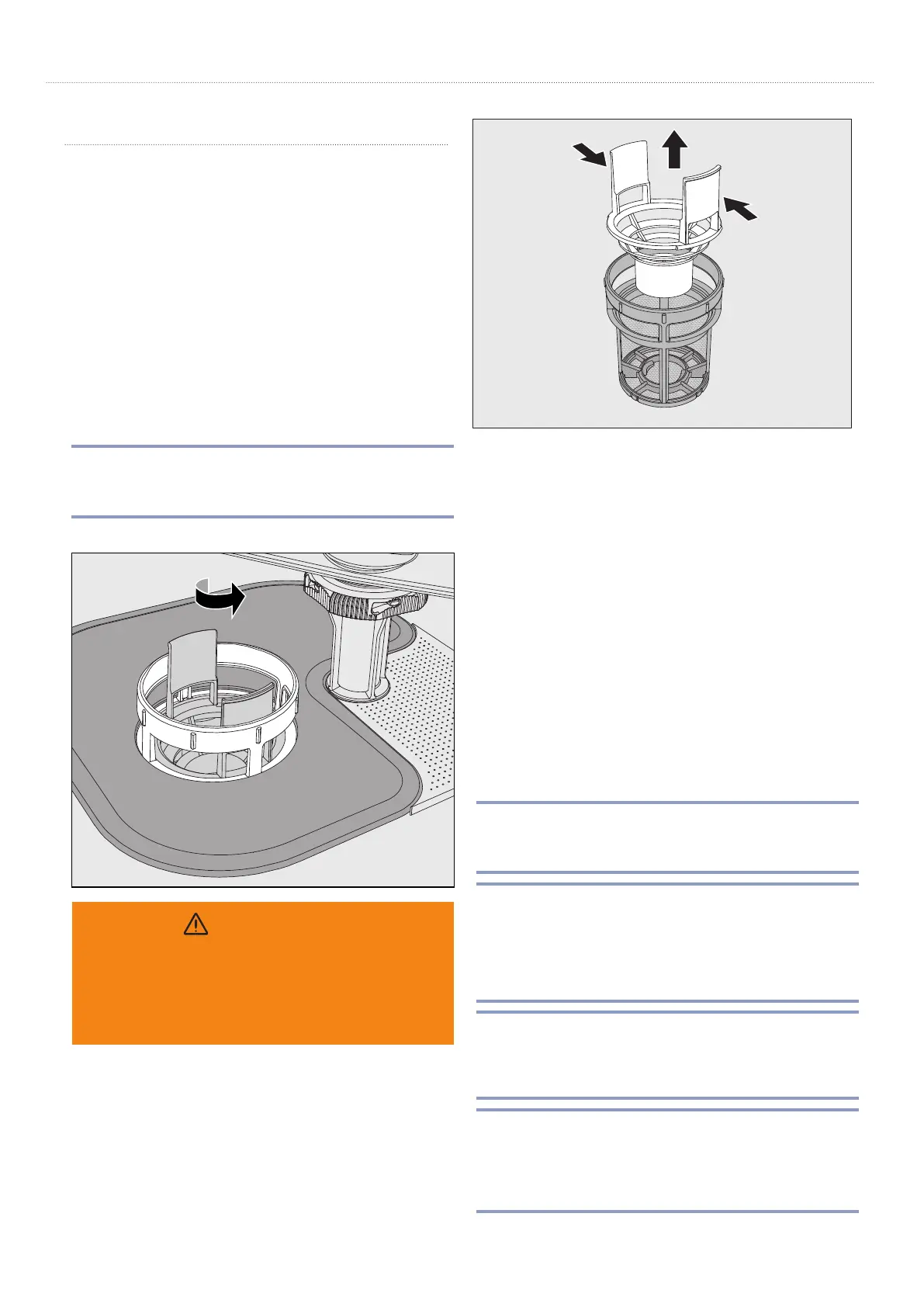

1. Turn the microne lter in the direction of the arrow and

remove together with the coarse lter.

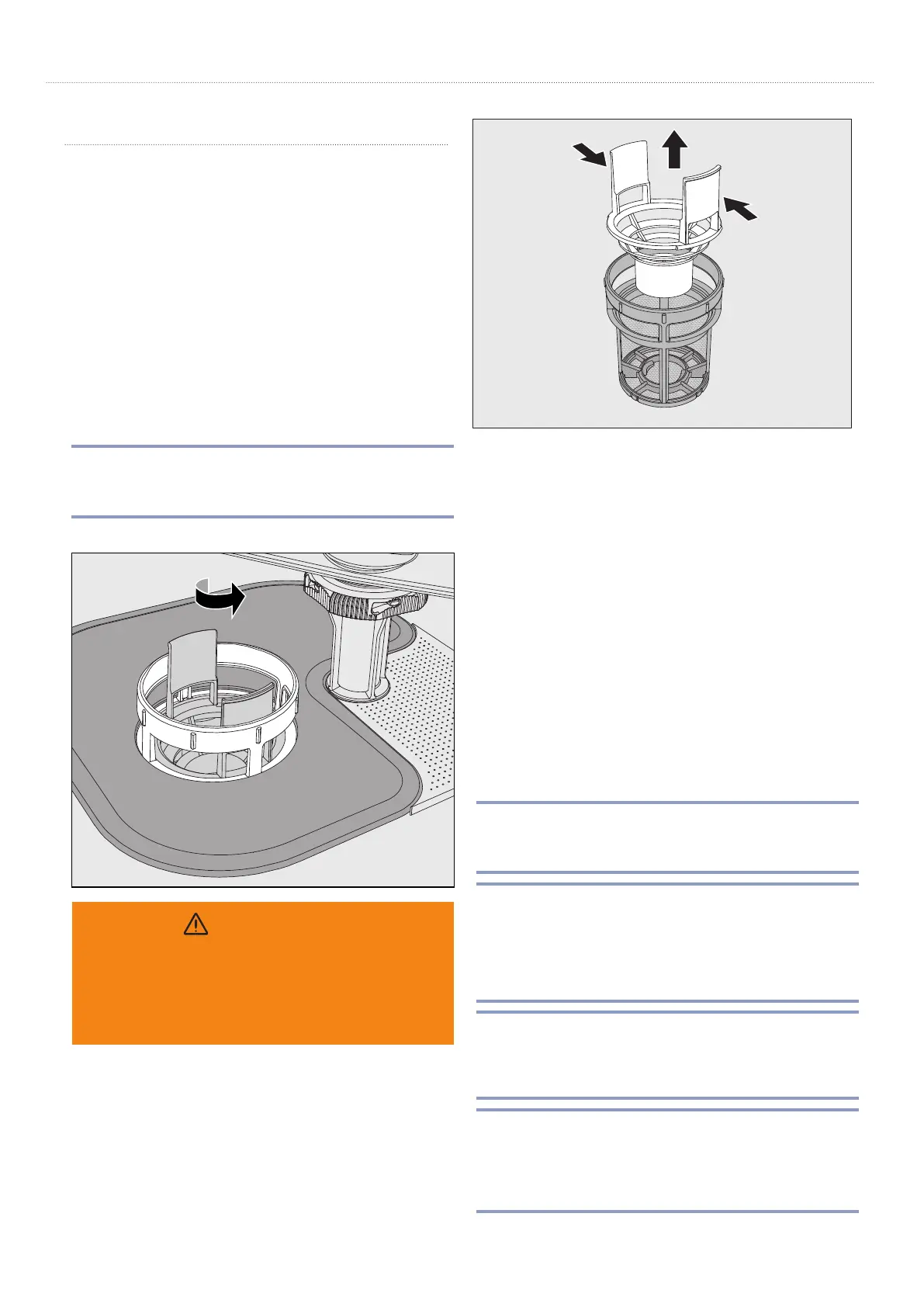

2. Press the catches towards each other and pull the

coarse lter upwards and remove it.

3. Remove the ne lter which sits loosely between the

coarse lter and the microne lter.

4. Remove the at lter last.

5. Clean the lters in the manual wash sink.

6. Re-insert the lter combination in the reverse order.

Ensure:

• that the at lter sits at in the base of the wash

cabinet.

• that the coarse lter has securely clicked into

place in the microne lter

• that the microne lter is tightly screwed in as far

as it will go.

Cleaning the spray arms

The spray arms can become blocked, especially if the lters

are not inserted correctly in the wash cabinet. This can

cause coarse particles of soiling to get into the wash uid

circulation.

Spray arms must be visually checked daily for soiling and

blocked jets, and for ease of turning.

- CAUTION

Immobile or blocked spray arms must not be used

again. In this case contact Eschmann for advice.

- CAUTION

Do not allow any magnetic objects or wash items

to stick to the magnets on the spray arms.

Any metallic objects on the magnets can cause a

false reading of spray arm rotation.

Remove all metallic objects from the magnets.

- CAUTION

Visible wear on the bearings can adversely aect

the long-term functioning of the spray arms. In this

case, contact Eschmann

- CAUTION

Some spray arms and baskets are marked with a

number. When retting, ensure that the numbers

on the spray arms correspond with the numbers

on the baskets.

Maintenance

107

Press the catches towards each other and pull the coarse filter

upwards to remove it.

Remove the fine filter which sits loosely between between the

coarse filter and the microfine filter.

Remove the flat filter last.

Clean the filters.

Re-insert the filter combination in the reverse order. Ensure ...

– ... that the flat filter sits flat in the base of the wash cabinet.

– ... that the coarse filter has securely clicked into place in the

microfine filter.

– ... that the microfine filter is tightly screwed in as far as it will go.

Maintenance

106

Routine checks

Before the start of each working day the user must carry out a

number of routine checks. A check list is supplied with the machine

for this purpose.

The following need to be inspected:

– All filters in the wash cabinet

– The spray arms in the machine and in any mobile units or baskets

– The wash cabinet and the door seal

– The dispensing systems and

– Mobile units, baskets, modules and inserts.

Cleaning the filters in the wash cabinet

The filters in the floor of the wash cabinet prevent coarse soiling from

coming into contact with the circulation system. Filters can become

blocked by soiling, so they need to be checked every day and

cleaned as necessary.

This machine must not be used without all the filters in place.

Danger of injury from glass shards, needles etc which are

retained in the filter.

Turn the microfine filter in the direction of the arrow and remove it

together with the coarse filter.

WARNING!

PERSONAL INJURY HAZARD

Danger of injury from glass shards & needles etc,

which are retained in the lter.

Wear appropriate personal protective equipment.

5. User Maintenance

Loading...

Loading...