Do you have a question about the Mindray BA-88A and is the answer not in the manual?

| Light source | Halogen lamp |

|---|---|

| Display | 7 inch touch screen |

| Printer | Thermal printer |

| Interface | RS232 |

| Wavelengths | 340, 405, 546, 578, 630nm |

| Carry-over | < 1% |

| Power Supply | AC 100~240V, 50/60Hz |

| Operating Temperature | 15-30°C |

Details the meaning and interpretation of various safety symbols used throughout the manual.

Provides instructions to prevent electric shock, including warnings about opening covers and handling power.

Details necessary precautions to prevent biohazardous infection when handling samples.

Defines the system's intended application as an in vitro quantitative analyzer for clinical chemistries.

Specifies that the system must be operated by trained clinical professionals or authorized personnel.

Provides essential guidelines for operating the system safely and efficiently, including calibration and QC.

Details standard maintenance procedures, including cleaning, power management, and part replacement guidance.

Step-by-step guide for receiving, moving, connecting, powering on, and testing the analyzer.

Highlights crucial safety warnings when working with circuit boards, including ESD protection.

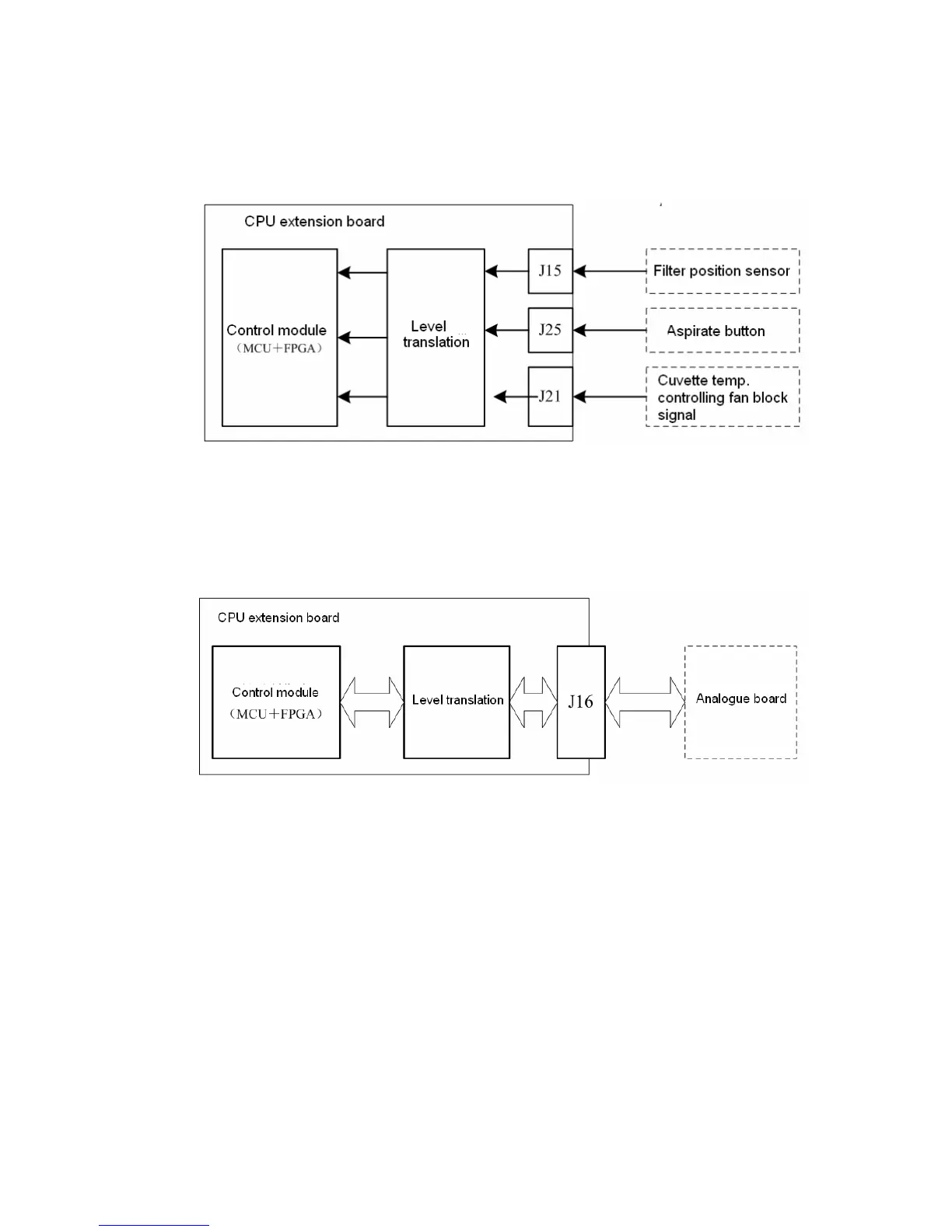

Illustrates the system's hardware connections and interfaces between various boards and external devices.

Explains how to upgrade system software using a U disk, detailing procedures for CPU and extension boards.

Provides detailed procedures for replacing consumable parts like tubing and lamps, and for replacing CPU boards.

Categorizes error messages based on severity and explains how logs record error details.

Classifies system failures into three levels to facilitate troubleshooting and identify common corrective measures.

Provides a comprehensive table detailing error codes, descriptions, causes, and corrective measures for various system failures.