8-2

Chapter 8 PERIODIC INSPECTION AND MAINTENANCE PROCEDURES

Fuel system

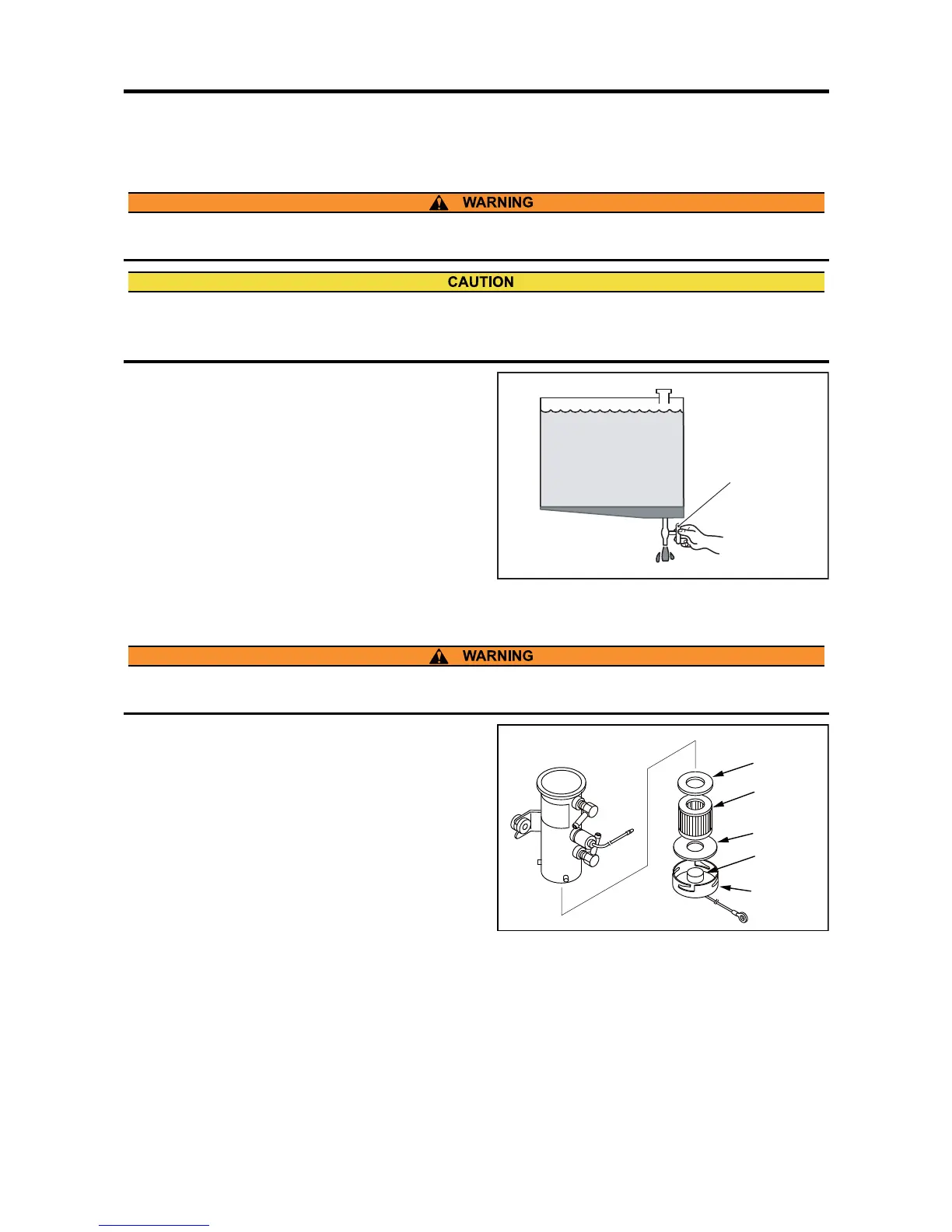

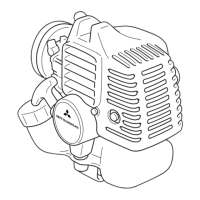

Fuel tank - Drain water

If fuel gets mixed with particles of foreign materials

such as dust, dirt, or water, it can cause not only

decrease of output but also malfunctions of the fuel

system. To avoid such a problem, drain fuel tank as

described below.

1. Place a fuel tray (capacity of 2 L [0.5 U.S. gal.] or

more) under the drain cock of fuel tank.

2. Open the drain cock of fuel tank and drain fuel at

least 1 to 2 L [0.3 to 0.5 U.S. gal.].

3. Make sure that water and particles of foreign mate-

rials discharged with fuel. Close the drain cock.

Fig. 8-2 Fuel tank - Drain water

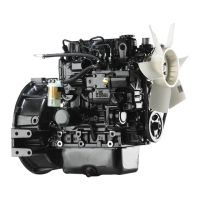

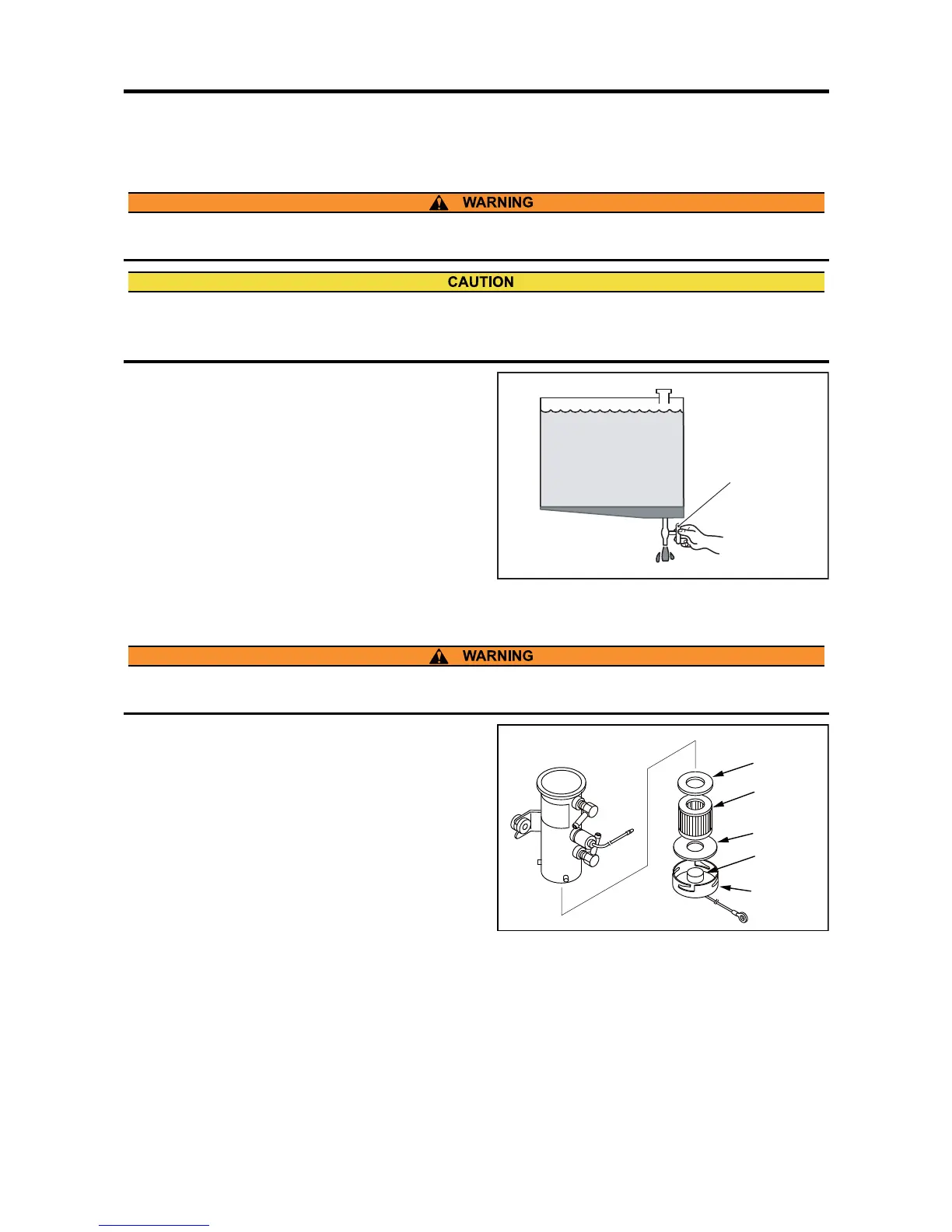

Solenoid fuel pump filter - Inspect and clean

1. Clean around the solenoid fuel pump.

2. Check the starter key is at the "OFF" position.

3. Place a fuel tray under the solenoid fuel pump.

4. Close the valve to stop fuel flow.

5. Remove the lower solenoid fuel pump cover.

6. Soak the gaskets, filter, magnet and cover in fuel to

clean.

7. Inspect if there is any damaged part, and if so,

change it for a new one.

8. Put all the parts back together in a reverse way.

9. Open the main valve of the fuel tank.

10. Turn the starter switch to the "ON" position.

11. Make sure that solenoid fuel pump clicks and fuel

starts to flow.

12. Check the solenoid fuel pump for fuel leakage. If

leakage is found, reassemble again.

13. Bleed air from the fuel system.

Refer to "Fuel system - Bleed air" (8-3).

Fig. 8-3 Solenoid fuel pump filter - Inspect and clean

When working around fuel, make sure there are no open flames, heaters or other fire hazards. Wipe off any spilled

fuel completely. Spilled fuel can ignite and cause a fire.

Do not remove the strainer when filling the fuel. For fuel to be used, refer to "FUEL" (4-1).

Bleeding water procedure described below is a commonly used procedure. Some application may be equipped

with different fuel tank.

Loading...

Loading...