8-3

Chapter 8 PERIODIC INSPECTION AND MAINTENANCE PROCEDURES

Fuel system - Bleed air

When cleaning or replaceing the parts of fuel system, perform air bleeding from each parts.

Note: Air in the fuel injection pipe and nozzle is discharged automatically by clanking of engine.

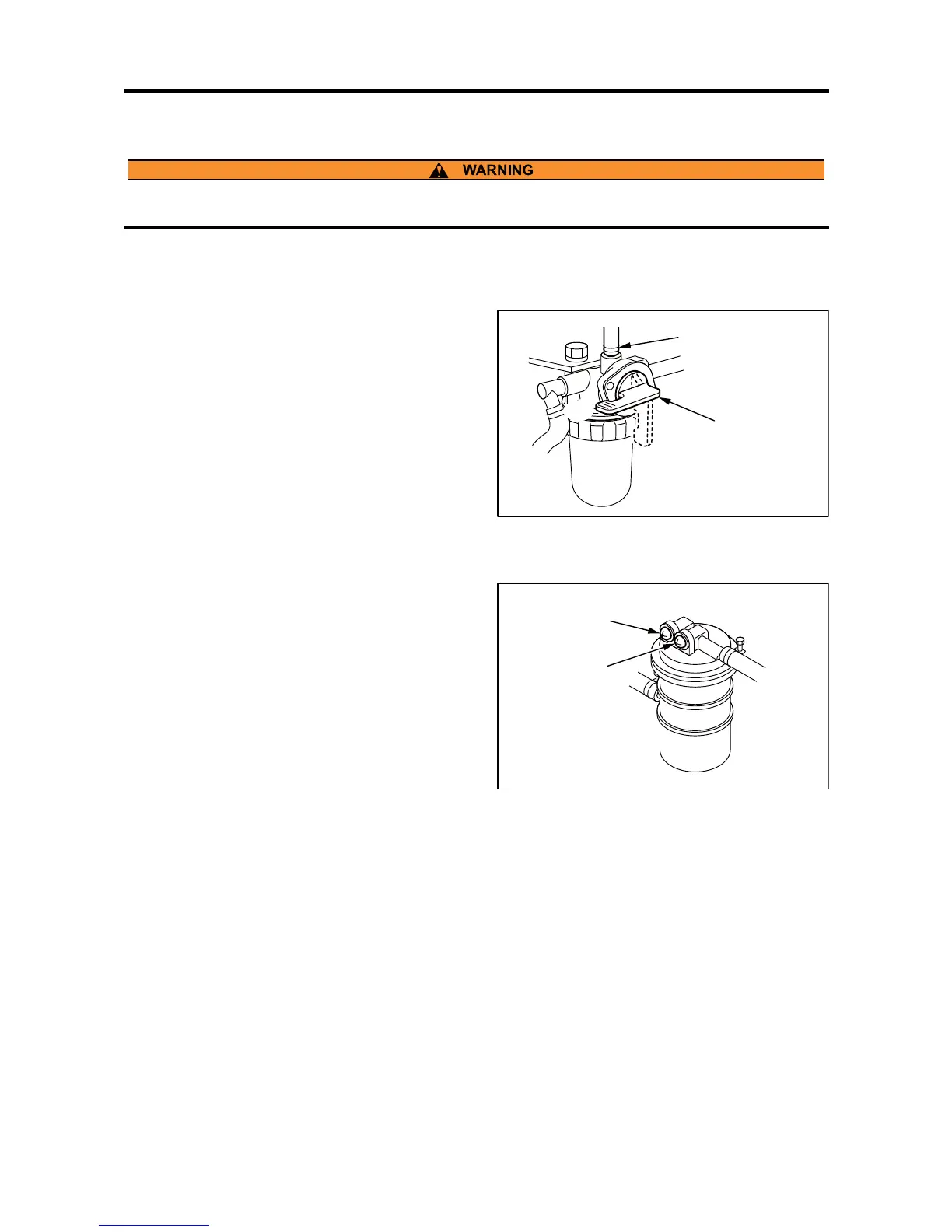

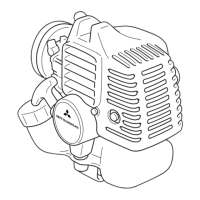

Fuel filter element (switching cock type) - Bleed air

1. Turn the fuel filter cock to "AIR" position.

2. Feed fuel using the solenoid fuel pump.

3. Return the cock to "ON" position when the fuel flow

from overflow pipe becomes free of bubbles.

4. Stop feeding fuel.

Fig. 8-4 Fuel filter element (switching cock type) -

Bleed air

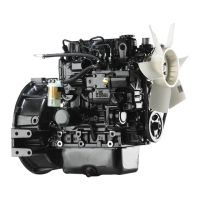

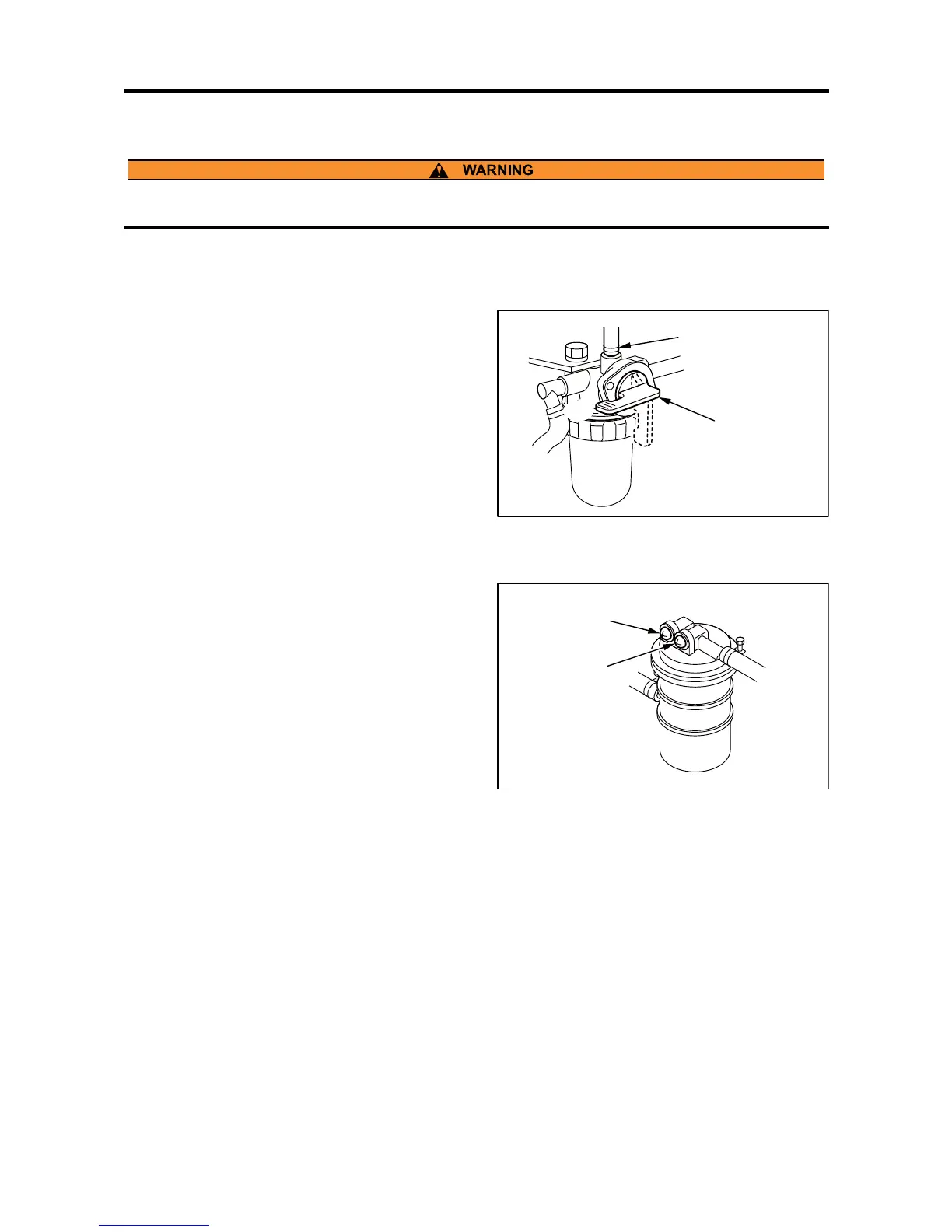

Fuel filters (cartridge type) - Bleed air

1. Loosen air vent plug 1 of fuel filter.

2. Feed fuel using the solenoid fuel pump.

3. When the fuel from the air vent plug 1 becomes

free of bubbles, stop priming and tighten the air

vent plug 1 to the specified torque.

4. Loosen air vent plug 2 of fuel filter.

5. When the fuel from the air vent plug 2 becomes

free of bubbles, stop priming and tighten an air vent

plug 2 to the specified torque.

6. Stop feeding fuel.

Fig. 8-5 Fuel filters (cartridge type) - Bleed air

When handling fuel, make sure there are no open flames or other fire hazards near the engine.

Wipe off any spilled fuel completely.Spilled fuel can ignite and cause a fire.

Loading...

Loading...