- 63 -

6.2 Servicing

(1) Evacuation

Evacuation refers to the process of purging non-condensable gas, air, water, etc. from the

refrigerant equipment with a vacuum pump.

The R410A refrigerant is highly water insoluble, therefore even a little water left in the refrigerant

equipment will be frozen, which causes the so-called water blockage.

The refrigeration oil of the compressor is esterification oil or synoil which has strong

hygroscopicity, so deposit may be formed easily when foreign matters enter, which causes many

inexplicable faults.

● Evacuation procedure

(a) Check whether there is internal pressure in the machine. If there is any, use the inspection

connector to eliminate it.

(b) Connect the service hose of the collecting pipe gauge to the gas and liquid pipes.

(c) Connect the vacuum pump to the charge hose . Conduct evacuation repeatedly in the

following order.

(2) Refrigerant charging

In case of leakage of R410A, be sure to discharge it all, evacuate the machine till the acceptance

value is reached, and charge new refrigerant according to the specified weight. Never add

refrigerant.

(a) Discharge all refrigerant from the machine and evacuate the machine.

Note: It is unreasonable to add refrigerant without evacuation, as this will cause insufficient or

excessive charging.

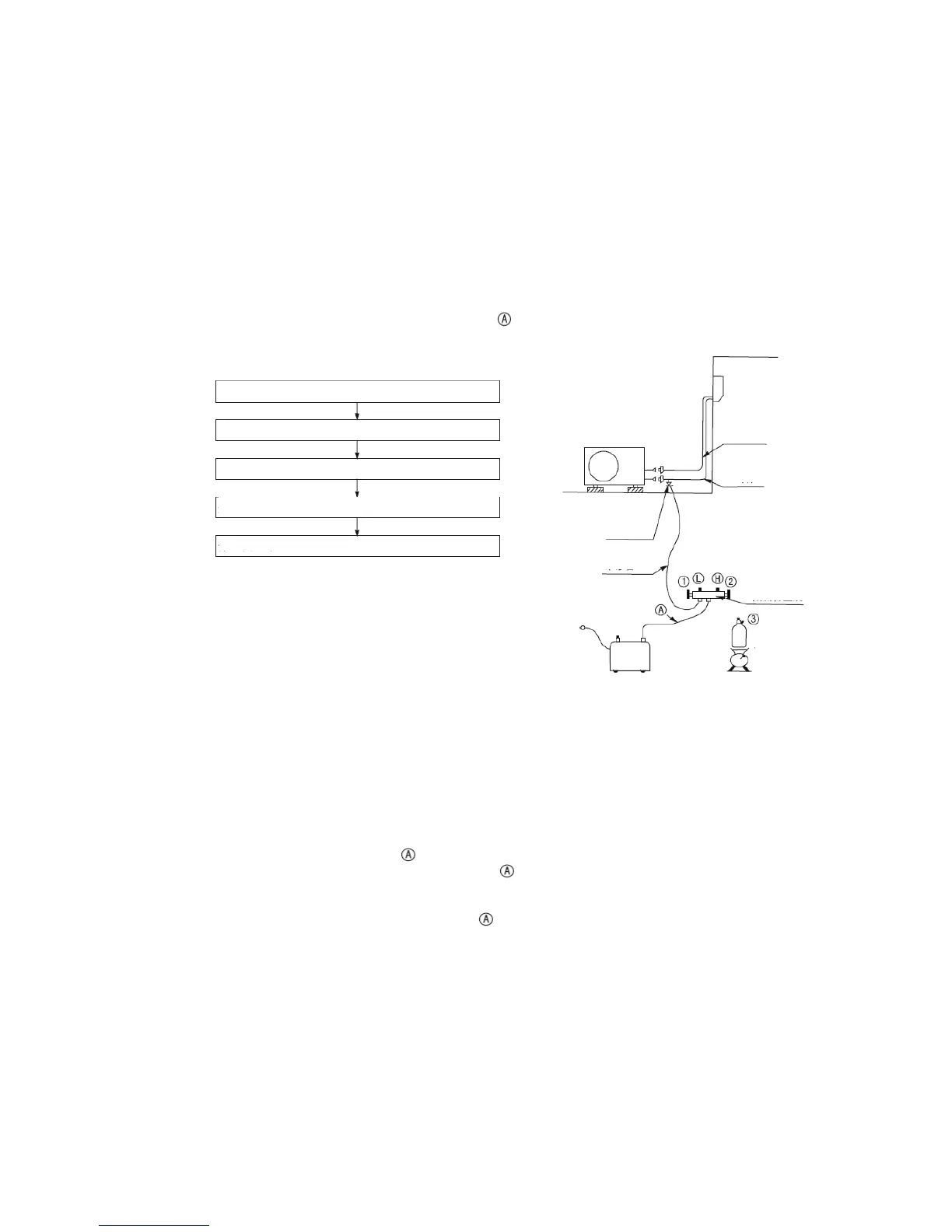

(b) Retain the collecting pipe gauge, and connect the refrigerant cylinder to the machine.

(c) Record the weight of the refrigerant cylinder on the scale. This is necessary to ensure the amount

of refrigerant to be charged.

(d) Purge the air in the charge hose .

Loosen the connection between the charge hose and the collecting pipe gauge; open the

valve ③ for several seconds; and tighten the connection immediately after the gas blown from

the loose part is observed.

(e) After the air is released from the charge hose , open the valves ① and ③ and the

refrigerant gas will immediately flow from the cylindar into the machine. Ensure the refrigerant

cylindar is kept vertical to allow the gas to flow into the machine.

(f) The refrigerant will not move several procedures after it is charged into the system. In such case,

start the compressor to start the cooling cycle, till the machine is fully charged with gas of the

specified weight.

(g) After the amount of refrigerant is determined, close the valve ③.

(h) Remove the charge hose from the mahine. Cover the valve mouth of the refrigerant pipe with the

blanking cover and tighten it.

(i) Use the gas leak detector to check for any leakage along the piping.

(j) Start the air conditioner, and ensure that its operation, the high/low pressure and temperature

difference between inlet air and outlet air, etc. are normal.

Loading...

Loading...