5.1.3.3

Relation

between

fixed

blade

and

movable

knife

(left)

edge

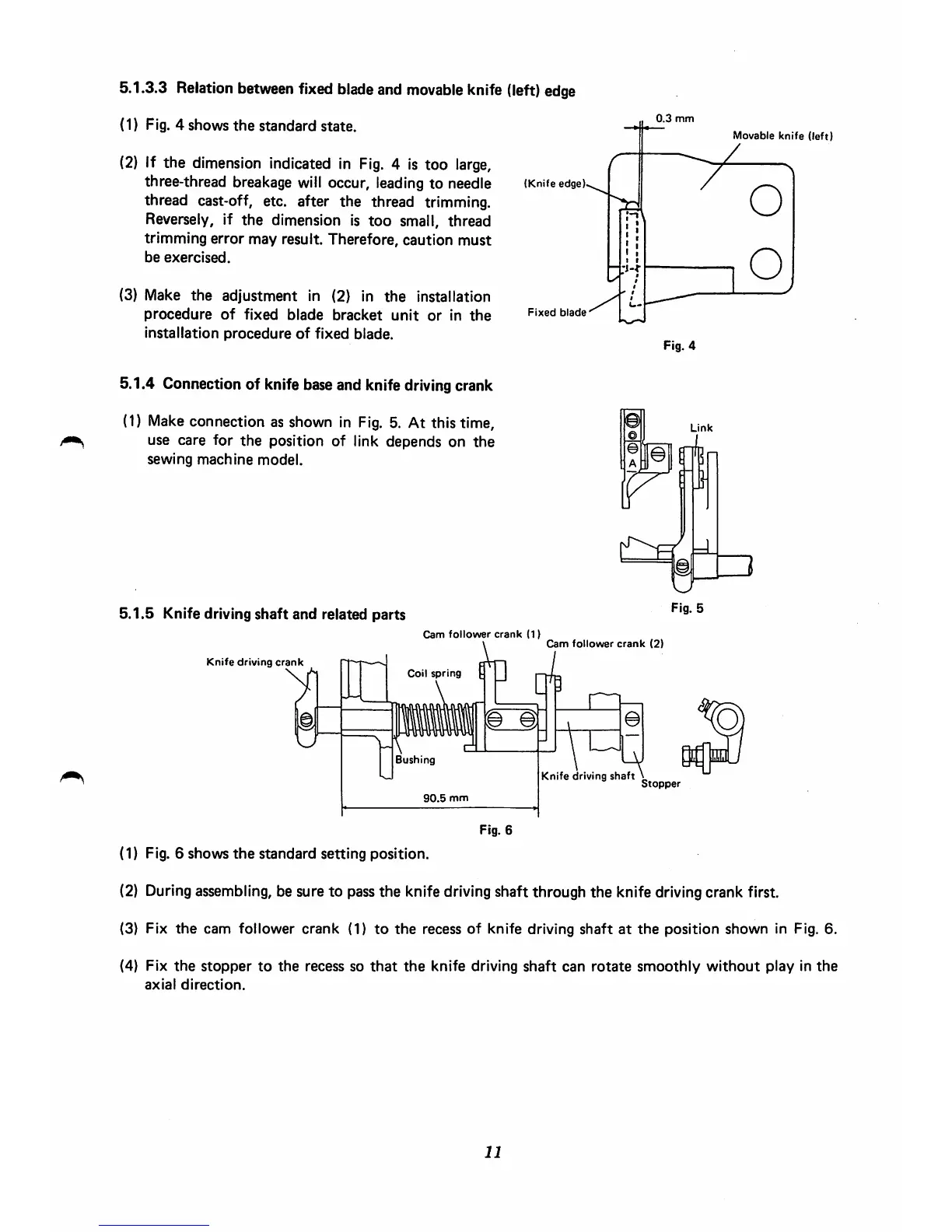

(1) Fig. 4 shows

the

standard

state.

(2) If the dimension indicated in

Fig.

4 is too

large,

three-thread breakage

will

occur, leading to needle

thread cast-off, etc. after the thread trimming.

Reversely, if

the

dimension is

too

small, thread

trimming error may result. Therefore, caution must

be

exercised.

(3) Make the adjustment in (2) in

the

installation

procedure

of

fixed

blade

bracket

unit

or

in

the

installation

procedure

of

fixed

blade.

5.1.4 Connection of knife base and knife drivingcrank

(1) Make connection as shown in

Fig.

5. At this time,

use care for

the

position of link depends on

the

sewing

machine

model.

5.1.5

Knife driving

shaft

and

related

parts

(Knife

edge)

Fixed

blade

0.3

mm

Fig. 4

Link

Fig. 5

Cam

follower

crank

(1)

Coil

spring

irer

crc

Cam

follower

crank

(2)

Knife

driving

crank

\

Bushing

30.5

mm

n

a

Knife

driving

shaft

Stopper

Movable

knife

(left)

/

Fig. 6

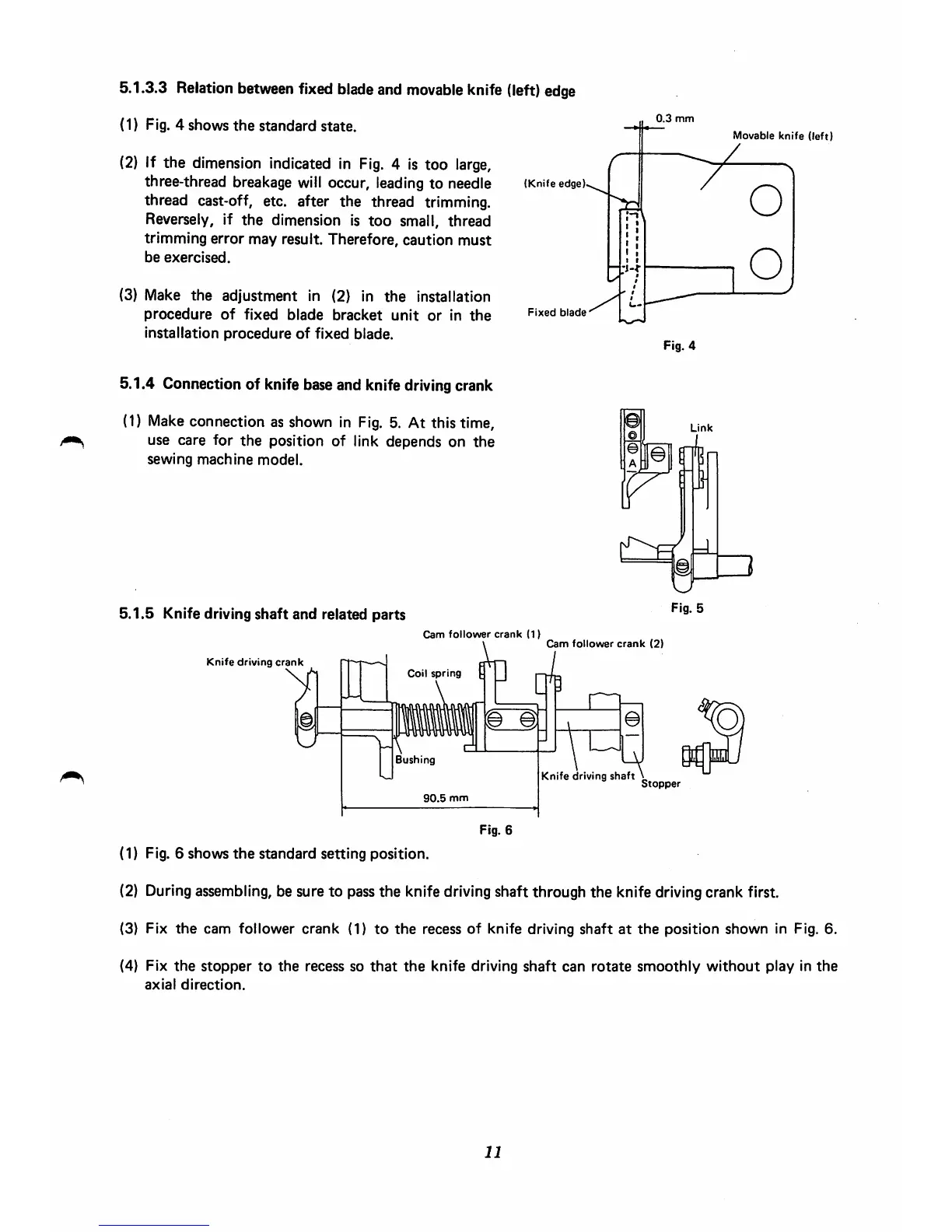

(1) Fig. 6 shows

the

standard setting position.

(2) Duringassembling, be sure to pass the knife drivingshaft through the knife drivingcrank first.

(3) Fix

the

cam follower

crank

(1)

to

the

recess

of

knife driving

shaft

at

the

position

shown

in Fig. 6.

(4)

Fix

the

stopper

to

the

recess so

that

the

knife

driving

shaft

can

rotate

smoothly

without

play

in

the

axial

direction.

11

Loading...

Loading...