49

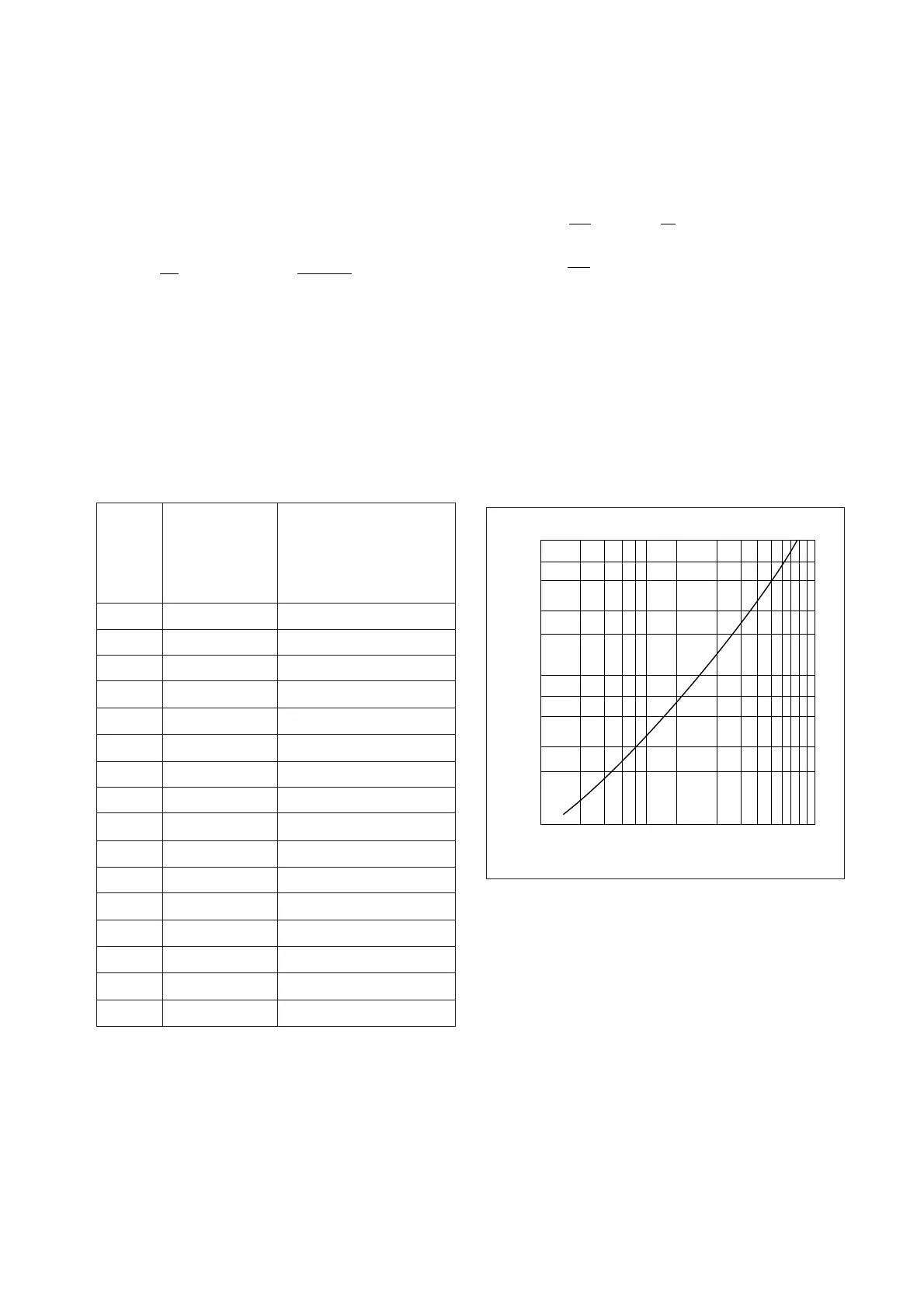

Table 6.4 Allowable Fault Conditions in Conductors

6.6 Protective Coordination with Wiring

6.6.1 General Considerations

If it is assumed that the heat generated by a large

current passing through a wire is entirely dissipated

within the wire, the following expression is applicable

(for copper wires):

(

S

I

2

t=5.05✕10

log

4

e

234+T

234+To

)

I : Current(A, rms)

S : Wire cross-sectional area(mm

2

)

t : Current let-through time(s)

T : Wire temperature due to short circuit(°C)

To : Wire temperature before short circuit(°C)

Assume that short-circuit current occurs in a wire car-

rying its rated current (hot state To=60°C). If 150°C is

the allowable temperature T, the following expression

is applicable (see also Fig. 6.13):

Is

Allowable short-circuit

current accoeding to I

2

t

kA, sym. (PF)

1

1.5

2.5

4

6

10

16

25

35

50

70

95

120

150

185

240

Allowable I

2

t

A

2

✕s

S

Wire size

mm

2

Notes: 1. Allowable I

2

t is calculated assuming that

all heat energy is dissipated in the

conductor, conductor allowable maximum

temperature exceeds 150°C, and hot

start is applied, at 60°C.

2. I

s

is an asym. value of allowable short-

circuit current reduced to below the

allowable I

2

t, assuming half cycle

interruption for 16mm

2

or less and one

cycle interruption for 25mm

2

or more.

Allowable I

2

t=14000S

2

Considering let-through energy (∫i

2

dt) in a fault where

the protector has no current-limiting capability, if short-

circuit occurs when let-through current is max., ∫i

2

dt

is:

where current le is the effective value of the AC com-

ponent. Half-cycle interruption is applied to wire of up

to 14mm

2

, and one-cycle interruption to larger wires.

Table 6.4 is restrictive in that, e.g., in a circuit of fault

capacity of 5000A or more, 2.5mm

2

wires would not

be permitted. In practice, the impedance of the con-

ductor itself presents a limiting factor, as does the in-

herent impedance of the MCCB, giving finite let-

through I

2

t and Ip values that determine the actual

fault-current flow.

6.6.2 600V Vinyl-Insulated Wire (Overcurrent)

Japanese Electrical Installations Technical Standards

(domestic) specify vinyl-insulated wire operating tem-

perature as 60°C max., being a 30°C rise over a 30°C

ambient temperature. This is to offset aging deterio-

ration attendant on elevated temperatures over long

periods. Criteria for elevated temperatures over short

periods have been presented in a study by B. W. Jones

and J. A. Scott (“Short-Time Current Ratings for Air-

craft Wire and Cable,” AIEE Transactions), which pro-

poses 150°C for periods of up to 2 seconds, and 100°C

for periods in the order of 20 seconds. These criteria

can be transposed to currents for different wire sizes

by the curves given in Fig. 6.14. Such figures, how-

ever, must be further compensated for the difference

between vinyl materials used for aircraft and for

0.014✕10

6

0.032✕10

6

0.088✕10

6

0.224✕10

6

0.504✕10

6

1.40✕10

6

3.58✕10

6

8.75✕10

6

17.2✕10

6

35.0✕10

6

68.6✕10

6

126✕10

6

202✕10

6

315✕10

6

479✕10

6

806✕10

6

1.17 (0.9)

1.76 (0.9)

2.93 (0.9)

4.68 (0.9)

6.79 (0.8)

10.5 (0.6)

16.0 (0.5)

17.3 (0.3)

24.2 (0.3)

34.5 (0.3)

48.3 (0.3)

65.6 (0.3)

82.8 (0.3)

103 (0.3)

128 (0.3)

166 (0.3)

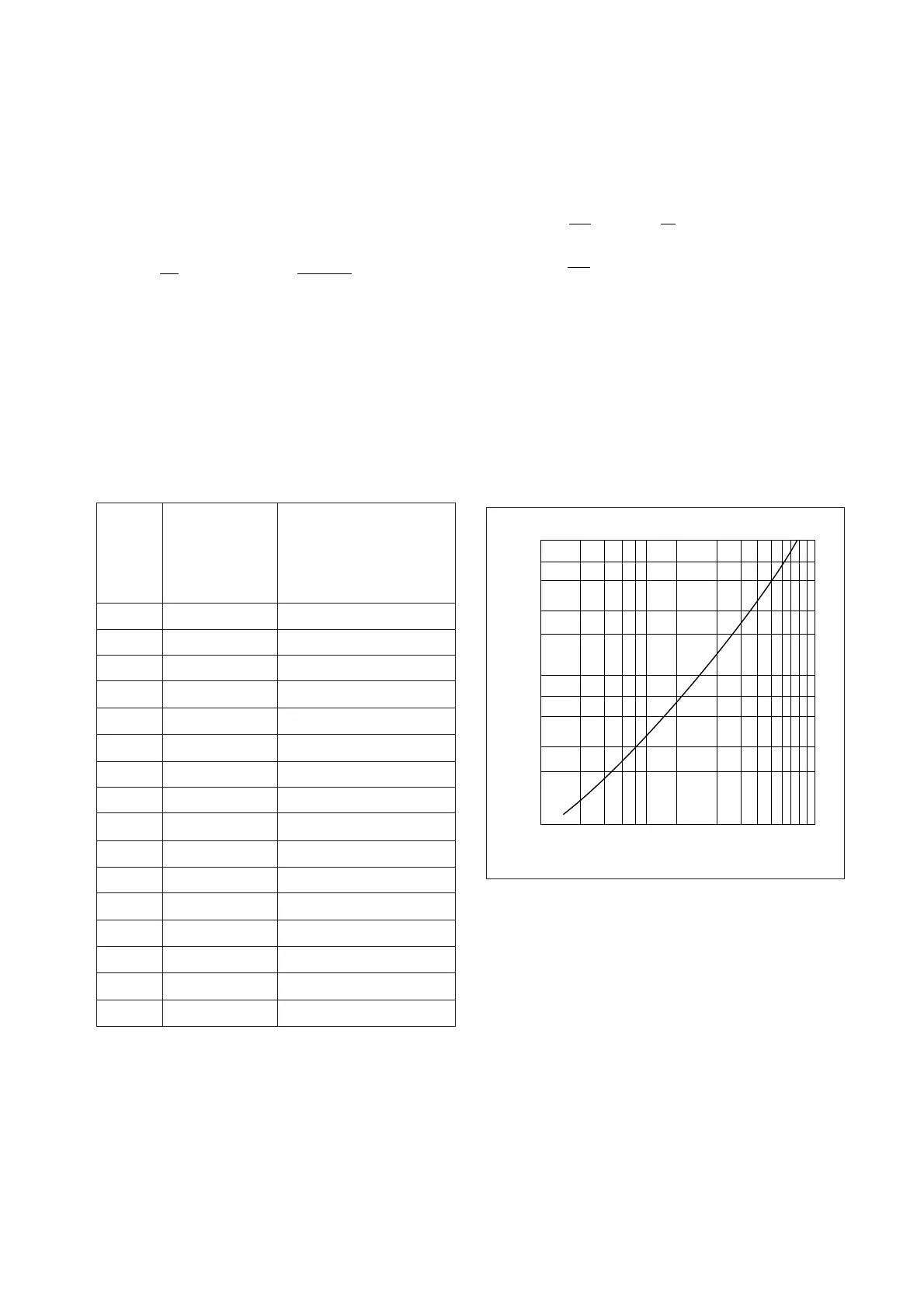

Fig. 6.13 Temperature Rises Due to Current Flow in Copper Wires

×10

3

×10

4

Temperature rise(°C)

1000

700

500

300

200

100

20

30

50

70

12 23344567856 1

(A/mm

2

)

2

·s

Approx.

71

Ie

2

(A ·s) in

2

2

1

cycle interruption

(Power factor is 0.5.)

Approx.

34

Ie

2

(A ·s) in 1

2

cycle interruption

(Power factor is 0.3.)

Loading...

Loading...