8 INSPECTION AND MAINTENANCE

Mitsubishi Diesel Engine S12R OPERATION & MAINTENANCE MANUAL

139

Pub. No. 291Y1-40720 Revision: 5

Gauze Filter - Clean

• For the location of the fuel supply

pump, refer to "2

ENGINE - OUTLINE"

(→ Page 75).

• Some parts such as joint and hose may

be outside the scope of our supply. For

the details, refer to such a document as

the specification sheet prepared by the

generator supplier.

• If it is not supplied by MHIET, follow the

instructions in the supplier's operation

manual.

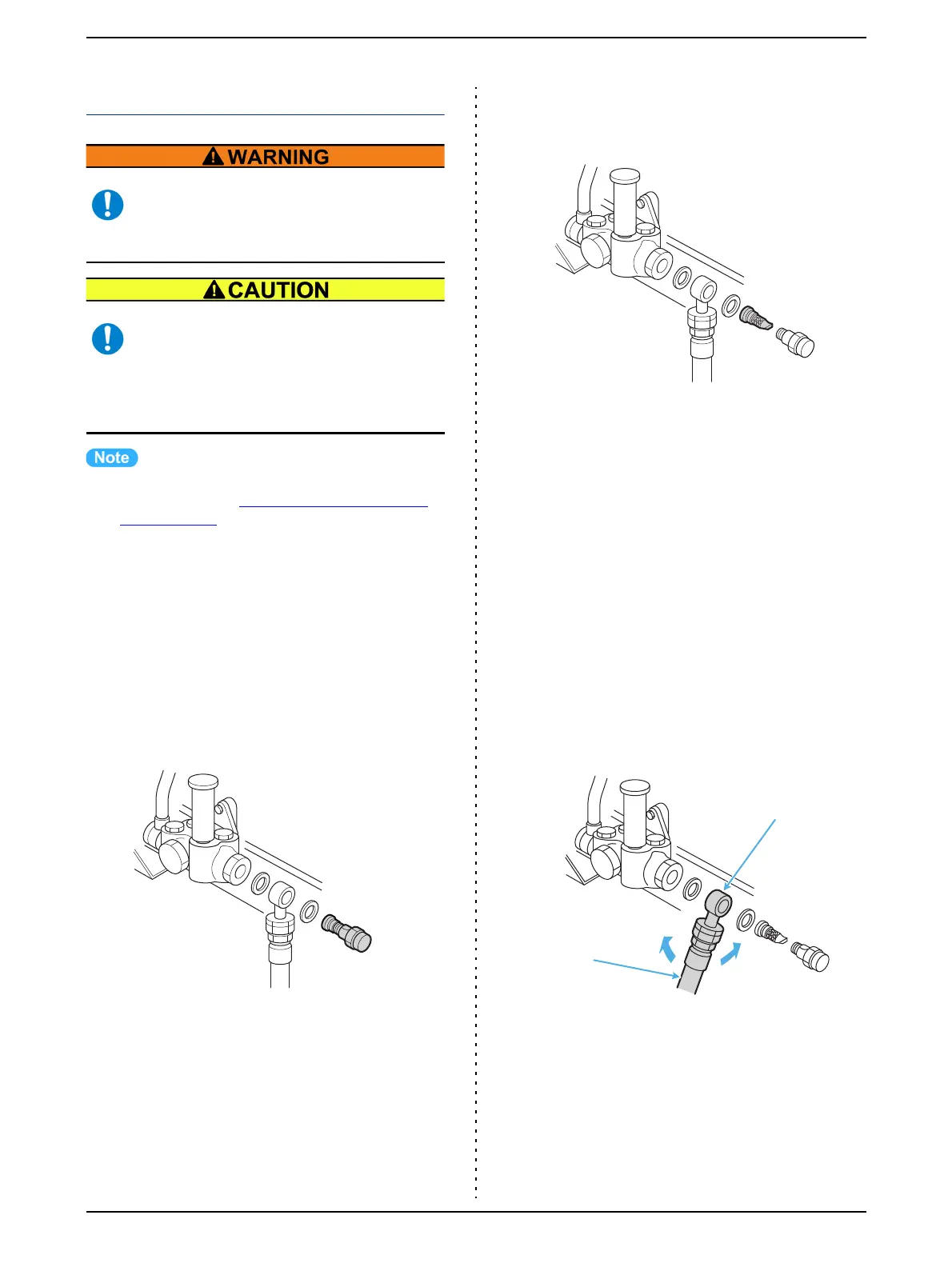

1 Remove the banjo bolt at the inlet

port of the fuel feed pump.

• Tool: Wrench

Fig. 8-27 Banjo Bolt - Remove

2 Remove the gauze filter that is fitted

inside the banjo bolt.

• Tool: Flat blade screwdriver

Fig. 8-28 Gauze Filter - Remove

3 Soak the gauze filter into fresh fuel

oil in the container, and wash it with

a soft brush or others.

• Replace the gauze filter with a new one, if it

has a break or deformation.

4 After cleaning, install the gauze filter

into the banjo bolt.

• Tool: Flat blade screwdriver

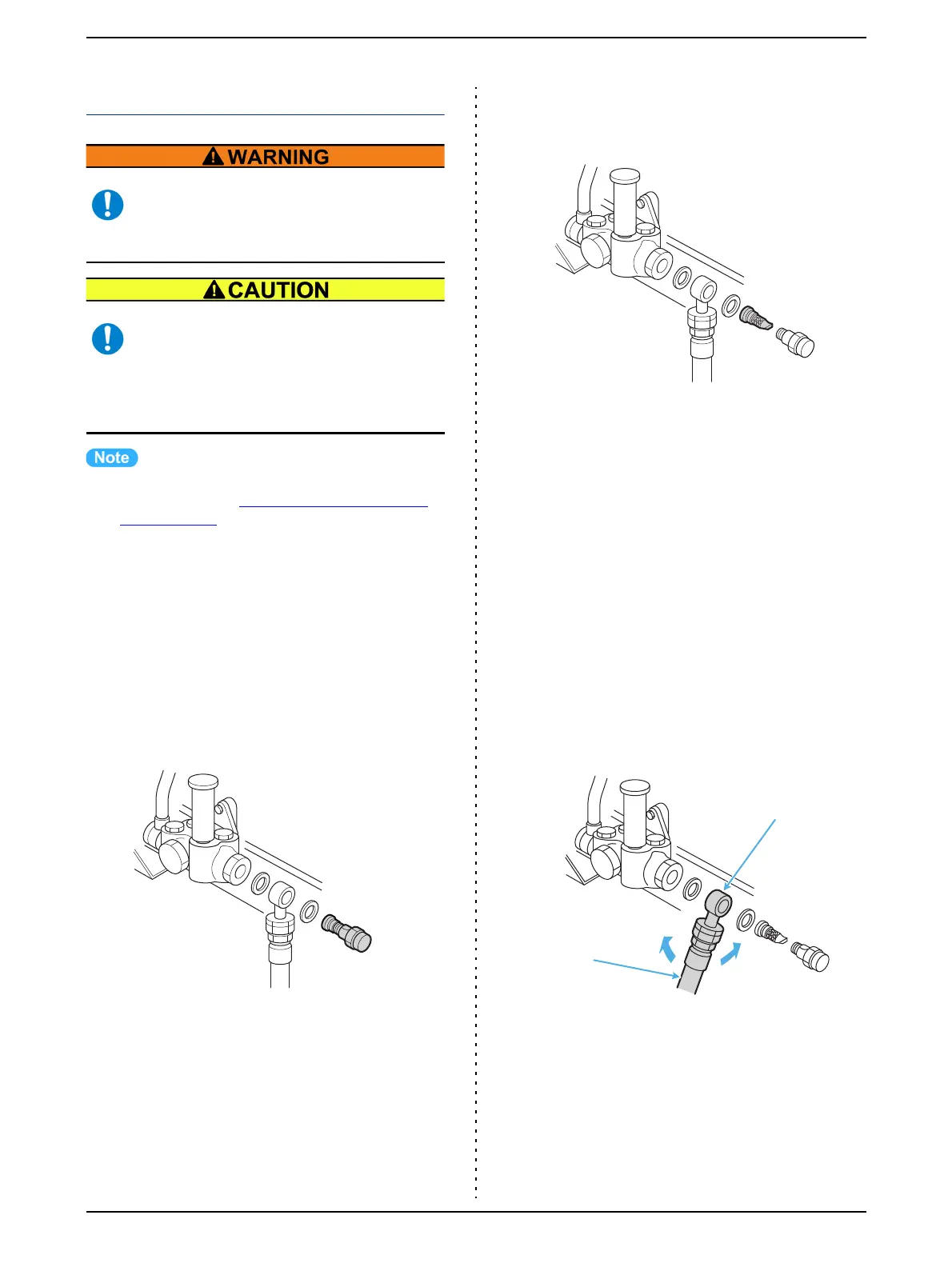

5 Align the phase and angle between

the joint (1) and the hose (2) as they

were when removed.

• Always replace the sealing washer with a

new one once it is disturbed.

Fig. 8-29 Hose Joint

Clean the gauze filter properly.

* A clogged gauze filter may result in insufficient

fuel supply, low power output, or engine stall

during operation.

When replacing the gauze filter,

tighten the new one under the same

condition as the old one was installed.

* Fuel leaks due to the tightening torque being

loose may cause a fire or fuel flow-out, which

results in environmental pollution.

(2)

(1)

Loading...

Loading...