INSPECTION AND REPAIR OF BASIC ENGINE

6-10

3. Inspecting and repairing timing gear, camshaft and oil pan

3.1 Inspecting V-pulley

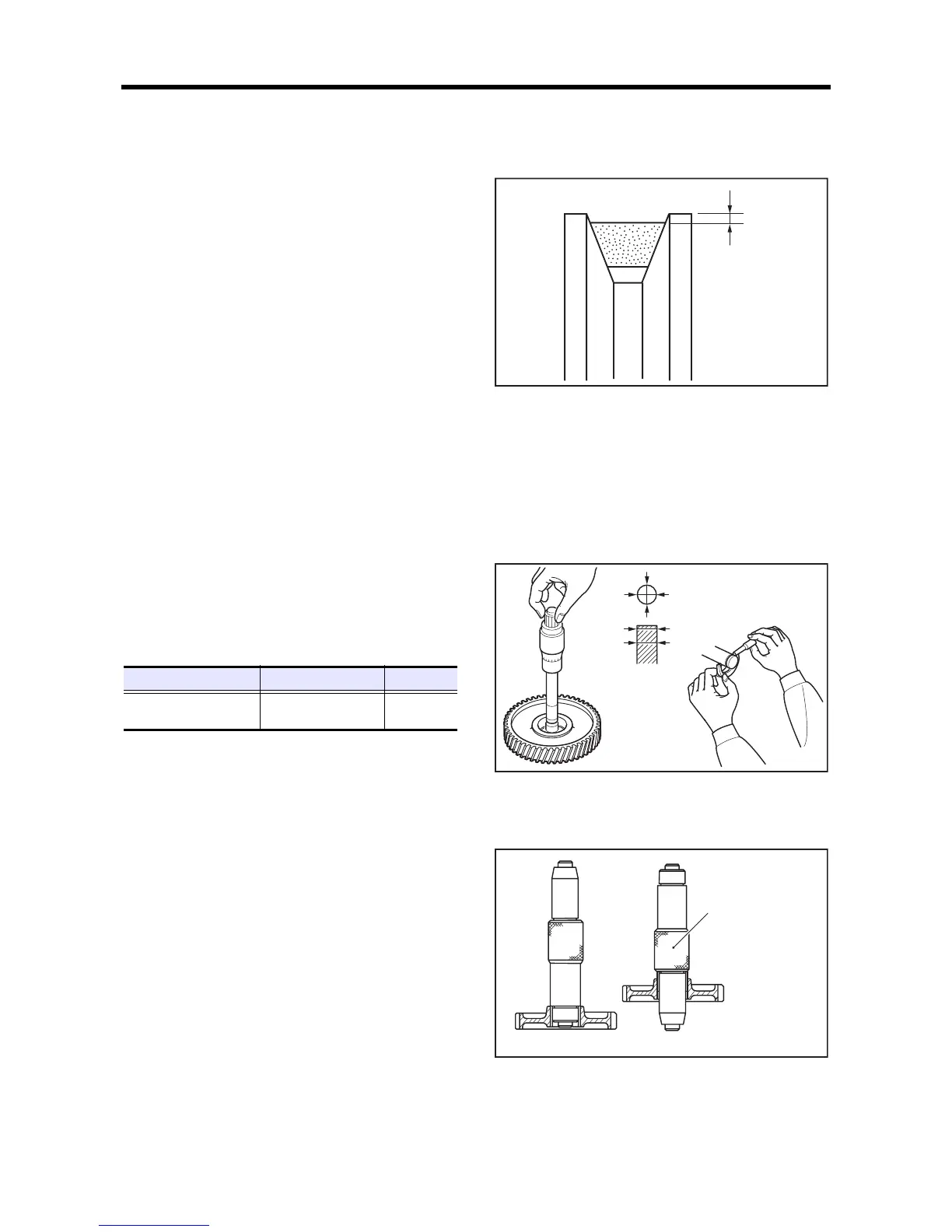

Check the V-belt groove of the pulley for wear. Attach a

new V-belt around a worn pulley, apply a high tension to the

belt, and check whether the top surface of the belt is outside

or inside of the pulley groove to determine the degree of

pulley groove wear.

When the top surface of V-belt is outside the pulley groove,

and the degree of wear is almost the same for every groove

(when pulley has two belt grooves or more), the remaining

service life of the pulley can be considered sufficient.

If the wear appears excessive, and the belt top surface sinks

1.6 mm or more down from the top edge of groove, the

pulley is not reusable. Replace the pulley with a new one.

Inspecting V-belt groove wear

3.2 Inspecting oil seal contact surface

Inspect the oil seal contact surface of the pulley. If the

pulley waers due to oil seal, replace the pulley with new

one.

3.3 Measuring clearance between idler bush-

ing and idler shaft

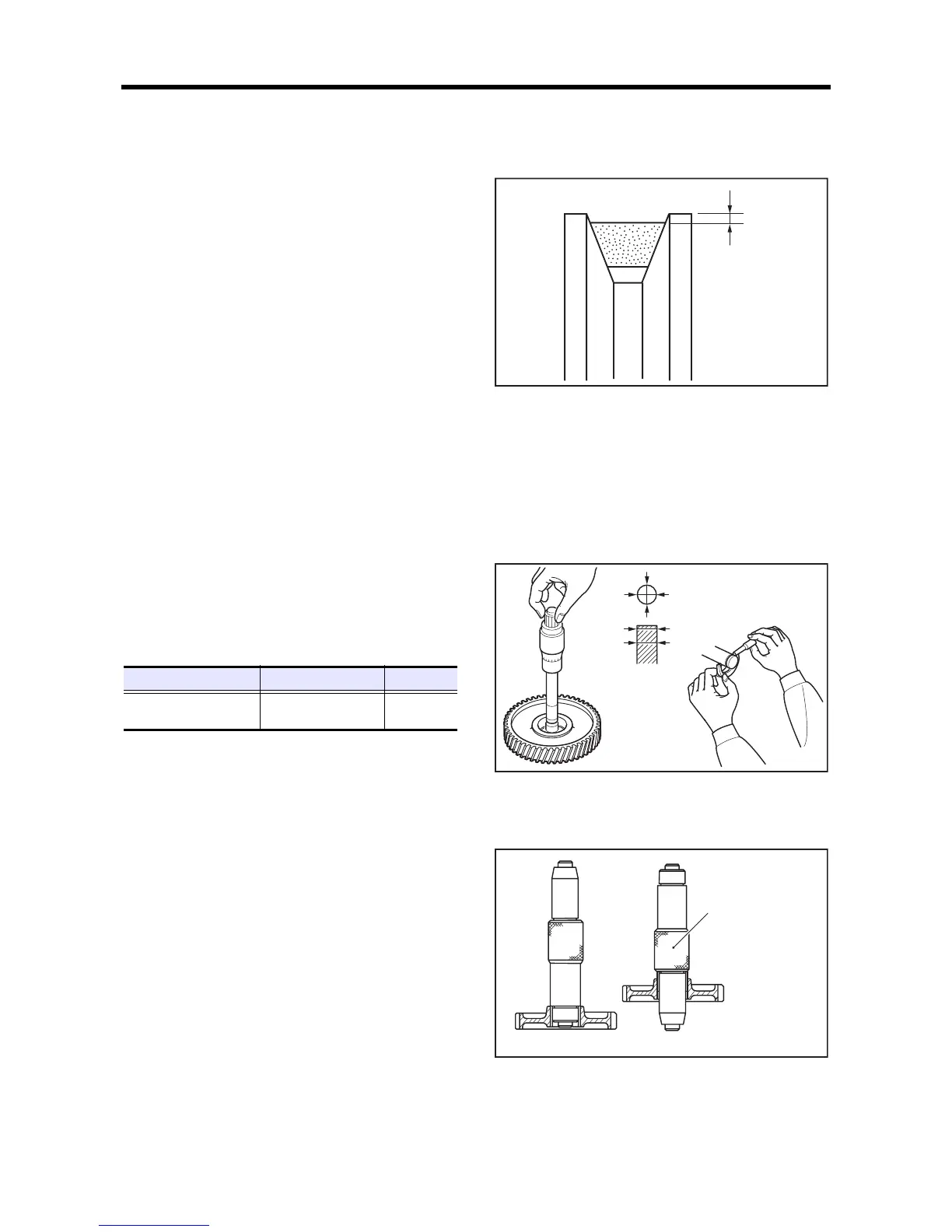

Measure the inside diameter of the idler bushing and outside

diameter of the idler shaft. Replace the bushing if the

clearance exceeds the limit.

Measuring idler bushing inside diameter and idler shaft

diameter

3.4 Replacing idler bushing

(1)

Use the idler bushing puller to replace idler bushing.

(2) To install the bushing, drive it from the boss side so that

it is flush with the gear boss face.

(3) After installing the bushing, measure the bushing inside

diameter, and if the inside diameter exceeds the

standard, ream the bushing.

Replacing idler bushing

1.6 mm [0.06 in.]

or more

Item Standard Limit

Clearance between idler

bushing and idler shaft

0.025 to 0.075 mm

[0.0010 to 0.0030 in.]

0.100 mm

[0.0039 in.]

Measuring directions

Measuring

points

Idler bushing puller

P/N:30691-51900

Removing Installing

Loading...

Loading...