Page 41 mrcool.com

Refrigerant Piping Connection

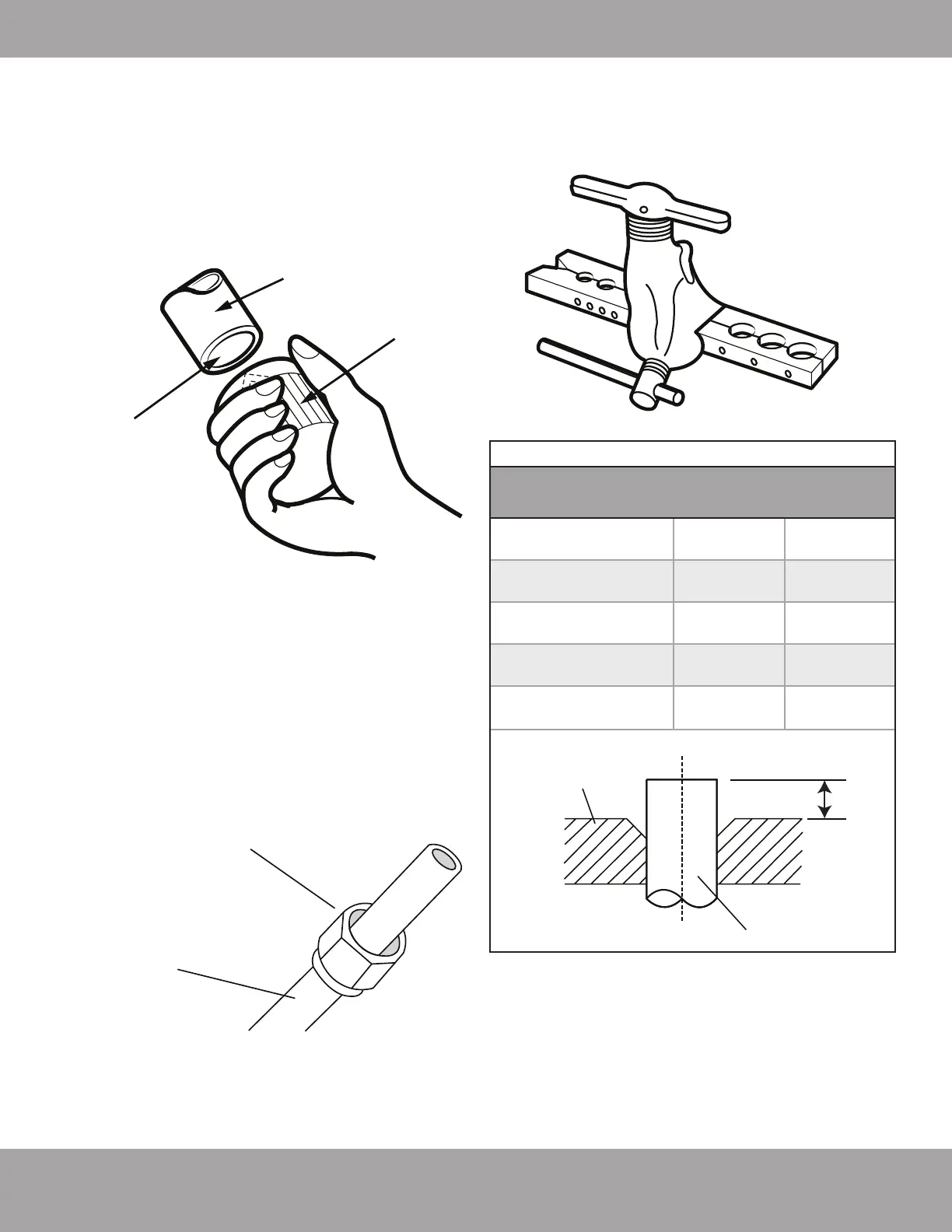

Step 2: Remove Burrs

Burrs can affect the airtight seal of the refrigerant

piping connections. They must be completely

removed from the piping ends before they can be

flared and connected.

1. Hold the cut section of the piping at a downward

angle in order to prevent the burrs from falling

into the pipe while they are being removed.

2. Using a reamer or deburring tool, remove all of

the burrs from the piping. Refer to Fig. 7.2 below.

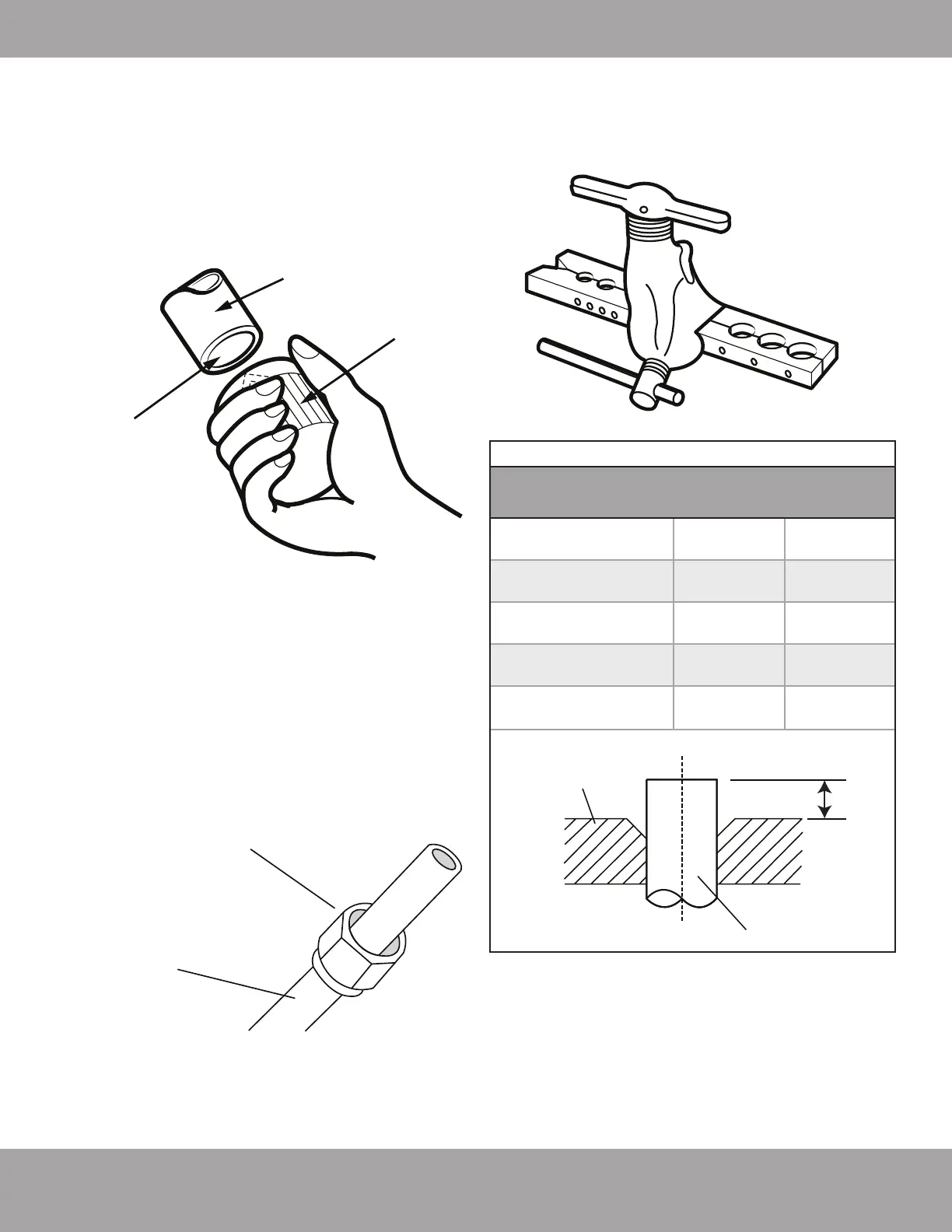

Step 3: Flare Pipe Ends

Proper flaring is essential for the refrigerant piping

connections to achieve an airtight seal.

1. Once the burrs have all been removed from the

cut pipe, seal the ends with PVC tape to prevent

any foreign materials from entering it.

2. Then, sheath the pipe with insulating material.

3. Place flare nuts on both ends of the pipe. Ensure

each of the nuts is facing in the correct direction.

Their direction cannot be changed nor can they be

replaced once the pipe end has been flared.

Please refer to Fig. 7.3 below.

4. Remove the PVC tape from both ends of the pipe

when you’re ready to flare the pipe.

Pipe

Reamer

Point down

Fig. 7.2

Flare nut

Copper pipe

Fig. 7.3

5. Clamp the flare form on the end of the pipe. The

end of the pipe must extend beyond the edge of

the flare form in accordance with the dimensions

in the table below. Please refer to Figs. 7.4 - 7.5.

PIPING EXTENSION BEYOND FLARE FORM

Outer Diameter

of Pipe

A

Fig. 7.4

Flare form

Pipe

A

Fig. 7.5

Flare Form

Min.

0.0275 in

(0.7 mm)

0.04 in

(1.0 mm)

0.04 in

(1.0 mm)

0.078 in

(2.0 mm)

0.05 in

(1.3 mm)

0.063 in

(1.6 mm)

0.07 in

(1.8 mm)

0.086 in

(2.2 mm)

Max.

Ø 0.25 in

(6.35 mm)

Ø 0.375 in

(9.5 mm)

Ø 0.5 in

(12.7 mm)

Ø 0.63 in

(16 mm)

0.078 in

(2.0 mm)

0.094 in

(2.4 mm)

Ø 0.75 in

(19 mm)

Units: inch (millimeter)

6. Place flaring tool onto the flare form. Refer to the

table at the bottom of the following page to find

the correct flare dimensions for the piping

diameter being flared.

7. Turn the handle of the flaring tool clockwise until

the pipe is fully flared.

8. Remove the flaring tool and the flare form from

the pipe. Inspect the end of the pipe for cracks

and that it has been flared evenly.

Loading...

Loading...