Page 44mrcool.com

8

Air Evacuation & Adding Refrigerant

Preparations & Precautions

Air and foreign matter in the refrigerant circuit can

cause abnormal rises in pressure, which can damage

the system, reduce its efficiency, and/or cause

personal injury. Use a vacuum pump and manifold

gauge to evacuate the refrigerant circuit and remove

any incondensable gas and moisture from the

system. NOTE: Evacuation should be performed

upon initial installation or when the unit

is relocated.

Before using the manifold gauge and vacuum pump,

read their operation manuals to familiarize yourself

with how to use them properly.

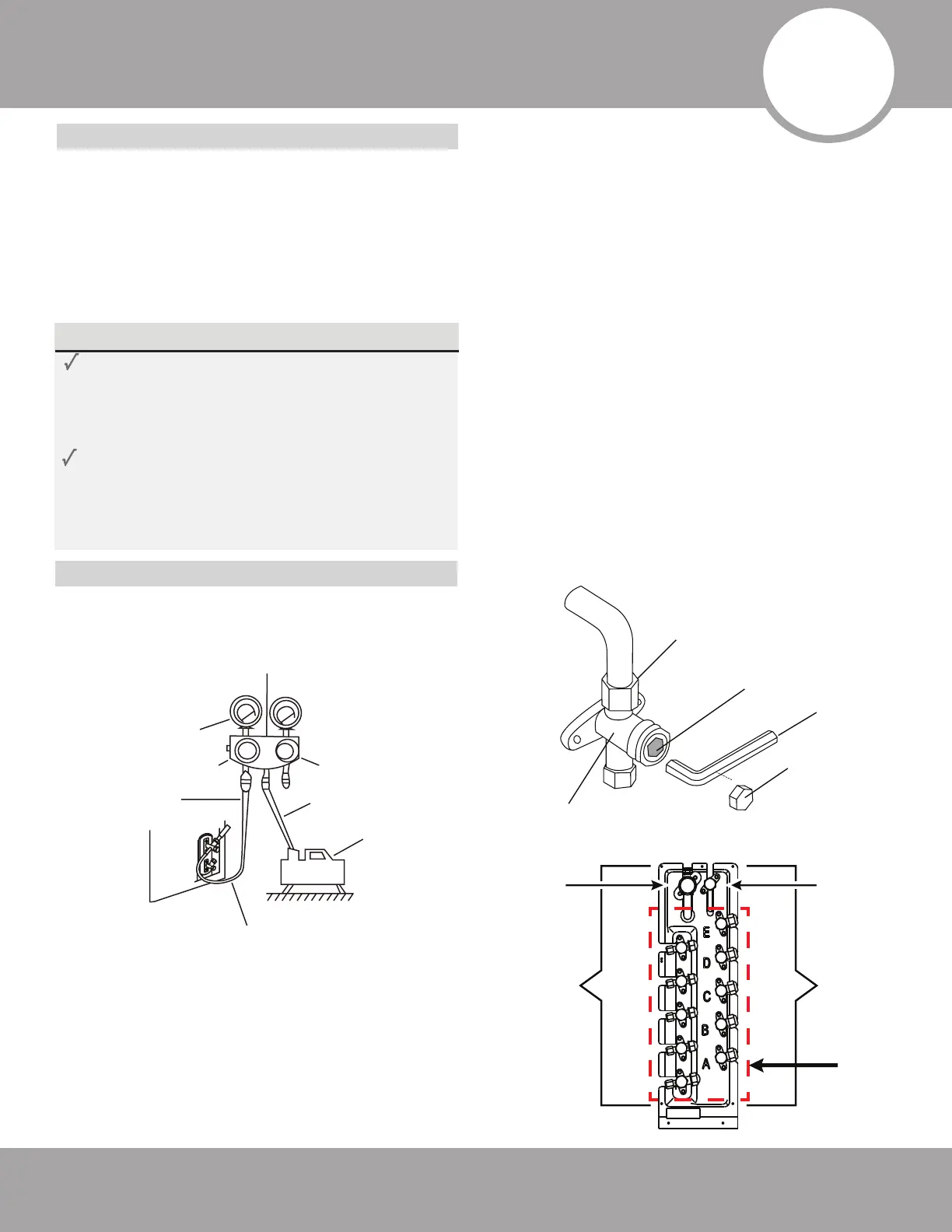

1. Connect the charge hose of the manifold gauge

to the service port on the outdoor unit’s low

pressure valve.

2. Connect another charge hose from the manifold

gauge to the vacuum pump.

3. Open the low pressure side of the manifold gauge.

Keep the high pressure side closed.

4. Turn on the vacuum pump to evacuate the system.

5. Run the vacuum for at least 15 minutes, or until the

compound gauge reads -76 cmHG (-10

5

Pa).

BEFORE PERFORMING EVACUATION

Check to make sure the refrigerant piping

between the indoor and outdoor unit is

connected properly and in accordance with

the Refrigerant Piping Connection section

of this manual.

Ensure all wiring is properly connected in

accordance with all local & national

electrical codes and the wiring diagram

located on the back of the outdoor

condenser wiring cover .

Evacuation Instructions

Manifold Gauge

Compound gauge

-76 cmHg (10

5

Pa)

Low pressure valve

High pressure

valve

Pressure hose/

Charge hose

Charge

hose

Vacuum

pump

Pressure gauge

Low pressure valve

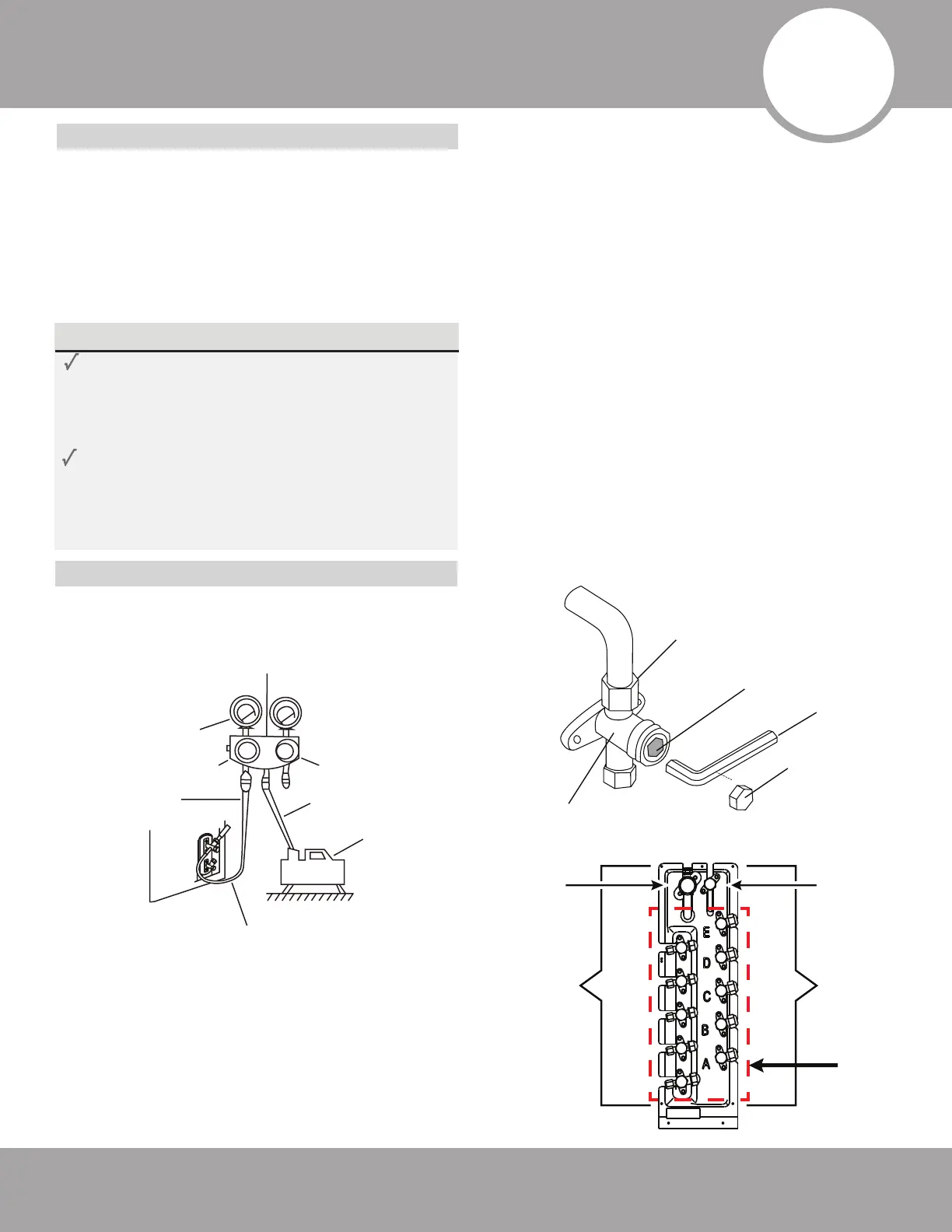

6. Close the low pressure side of the manifold gauge,

and turn off the vacuum pump.

7. Wait for a duration of 5 minutes, then check that

there has been no change in system pressure.

8. If there is a change in system pressure, refer to the

Gas Leak Checks section of this manual for more

detailed information on how to check the piping

and connections for leaks. If there is no change in

system pressure, unscrew the cap from the packed

valve (high pressure valve).

9. Insert an Allen/hexagonal wrench into the packed

valve (high pressure valve) and open the valve by

turning the wrench 1/4 turn counter-clockwise

(Refer to Fig. 8.1). Listen for gas to exit the system,

then close the valve after 5 seconds. If installing a

3, 4, or 5 zone multi-zone condenser, open all

of the high pressure valves connected to the

air handler piping 1/4 turn counter-clockwise

first. Now, open the high pressure main valve

1/4 turn counter-clockwise. Listen for gas to

exit the system, then close the main valve

after 5 seconds. Then, close all of the other

valves. Refer to Fig. 8.2.

Flare nut

Cap

Valve body

Valve stem

Fig. 8.1

Fig. 8.2

Low

Pressure

Main Valve

High

Pressure

Main Valve

“Liquid”

High

Pressure

“Suction”

Low

Pressure

Wrench

Air Handler

Connection

Valves

Loading...

Loading...