2200LZJE-HO-C6-N_2013.12.

Chapter 5 Maintenance

Compound 2-stage Screw Compressor 2016**C 5.7 Reassembly

5-65

b) In a normal state where the capacity control oil pressure pipe is not opened, move the unloader

piston by using a manual capacity control circuit. When the control power is turned on, keep the

indicator cover attached to avoid electrical shock. After the position of the piston is determined, turn

off the control power and conduct lockout/tagout. After that, remove the indicator cover and fix the

indicator needle.

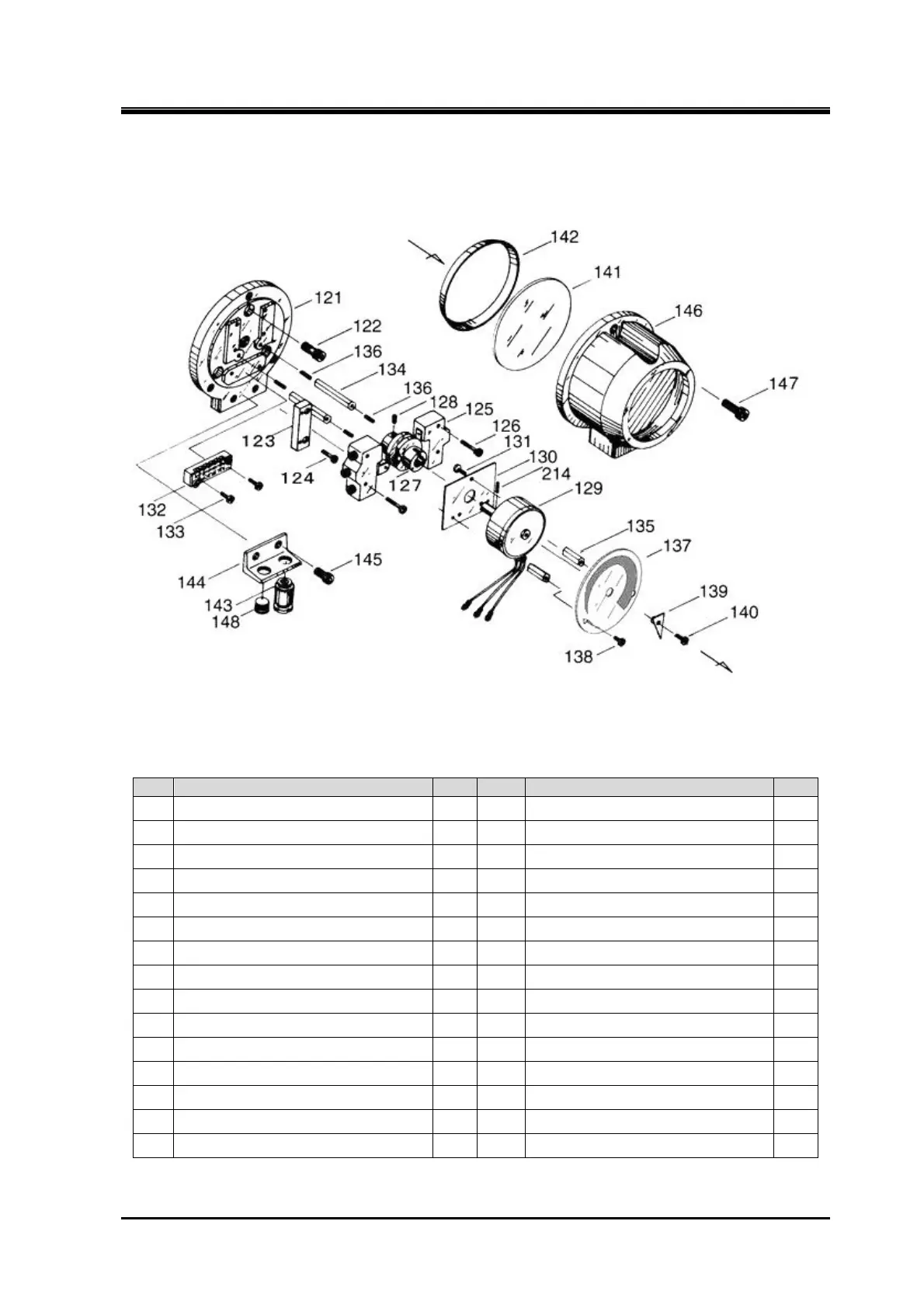

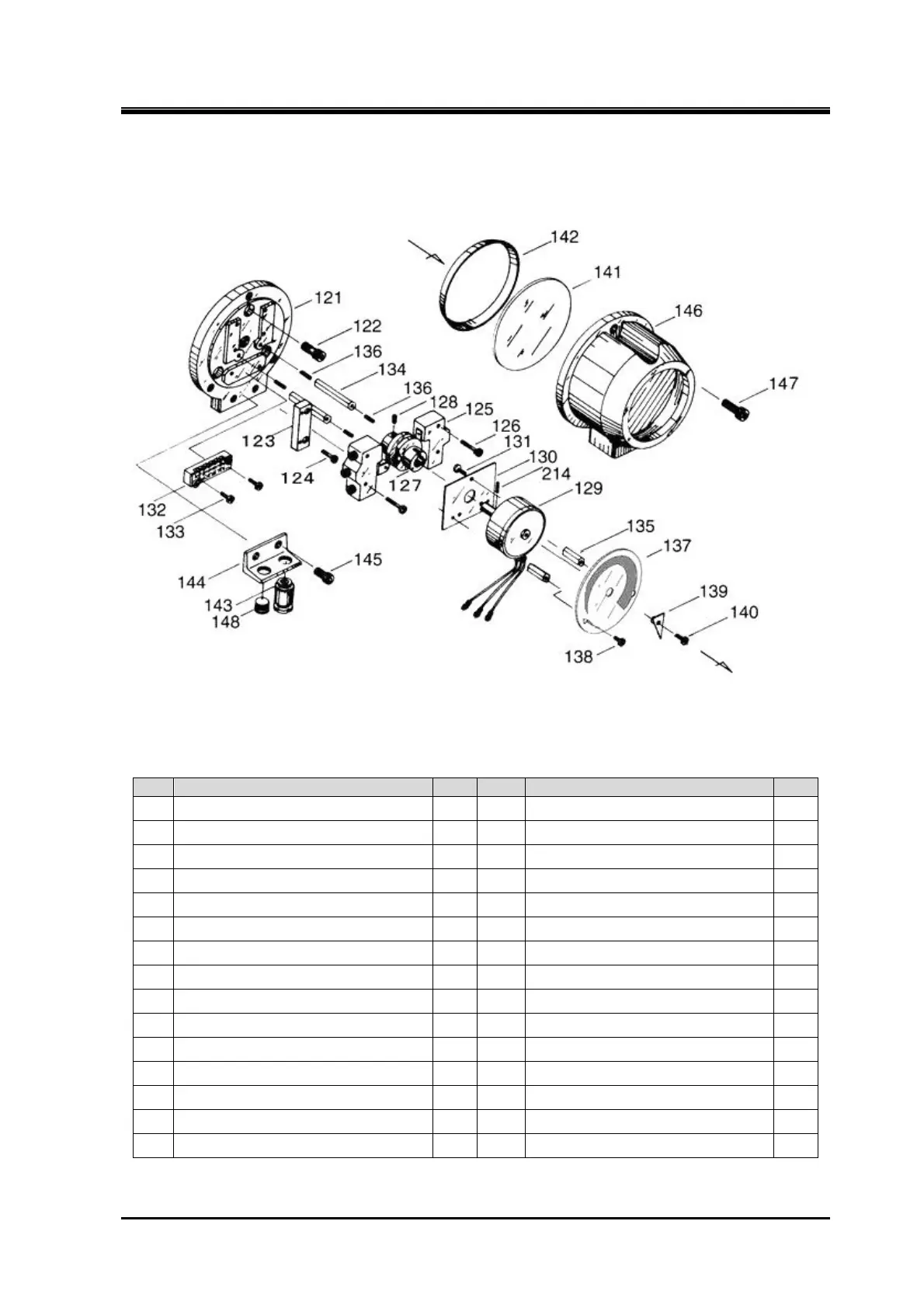

Figure 5-16 Development View of the 2016**C Standard-type High-stage Indicator

Table 5-12 Unloader Indicator Components (Standard type)

No. Part name Qty. No. Part name Qty.

121

Micro-switch base plate 1

136

Potentiometer mounting screw 3

122

Hexagon socket head cap screw 3

137

Indicator dial 1

123

Micro-switch set plate 1

138

Indicator dial screw 2

124

Philips screw 2

139

Indicator needle 1

125

Micro-switch 2

140

Indicator needle screw 1

126

Philips screw 4

141

Indicator glass 1

127

Micro-switch cam 1

142

Indicator glass spacer 1

128

Set screw 1

143

Electric wiring connector 1

129

Potentiometer 1

144

Connector support 1

130

Potentiometer set- plate 1

145

Hexagon socket head cap screw 2

131

Philips screw 3

146

Indicator cover (2) 1

132

Terminal block 1

147

Hexagon socket head cap screw 3

133

Philips screw 2

148

Plug 1

134

Potentiometer support arm [1] 2

214

Spring pin 1

135

Potentiometer support arm [2] 2 265-2 Spring washer 7

Loading...

Loading...