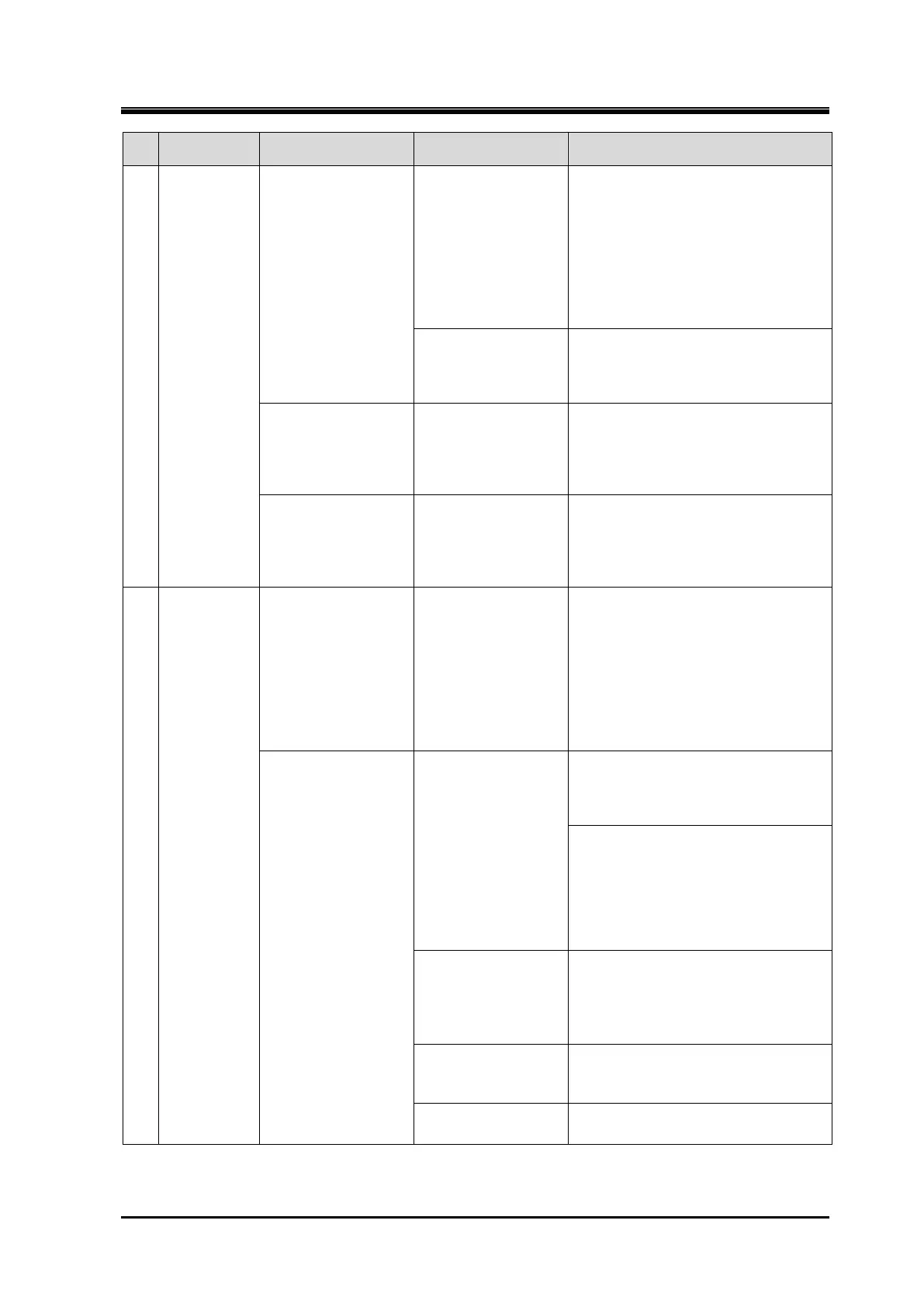

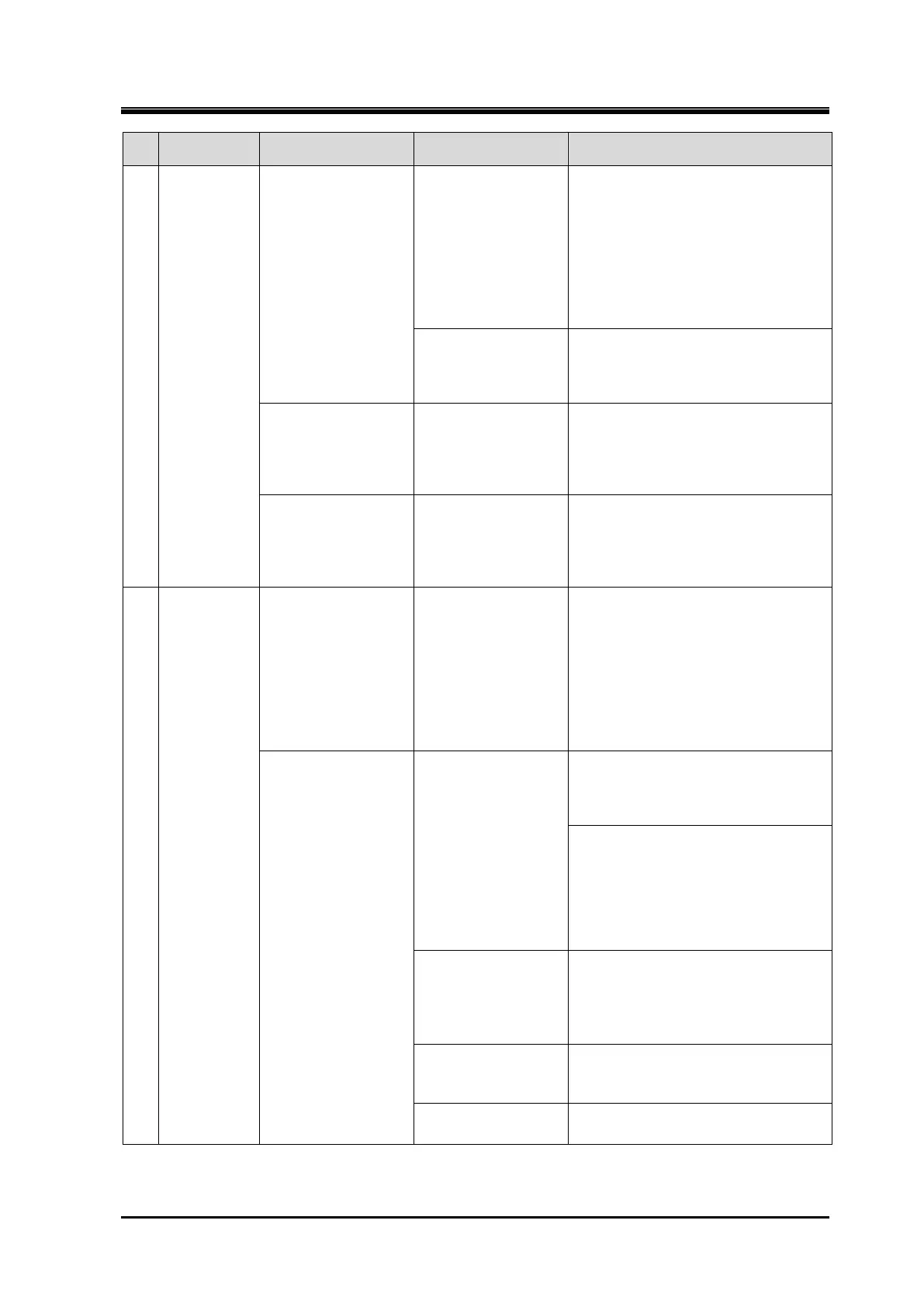

Chapter 6 Troubleshooting

UD-series Screw Compressors

6-5

Trouble Direct causes Factors Actions

high

discharge

temperature

temperature

failure in oil cooler

For water-cooled oil cooling, refer to

“Heat exchange failure at

condenser (heat exchanger)” in

item 05.

For liquid-injection oil cooling,

inspect liquid supply expansion

valve, temperature sensor, related

relays, wiring, terminals, etc., and

temperature

increase protection

Inspect temperature protection

device (switch), temperature

sensor, related relays, wiring,

terminals, etc., and take measures.

temperature

detection and

protection devices

temperature protec-

tion device,

temperature

Identify malfunctioning devices,

examine their causes, and take

measures.

Then, replace malfunctioning

oil

“Low hydraulic

pressure (low

oil-supply pres-

mechanical

seal

replacement until

mating surface(seal

and shaft) fit each

other.

mating surface.

For initial leak, amount of leak might

increase temporarily. However, it

will gradually decrease, so check

that the amount of leak does not

increase continuously.

Period of initial leak might differ

according to design and operating

conditions. 200 hours can be a

surfaces due to

excessive heat of

sliding surfaces

to excessive

repetition of

compressor

start/stop.

*Under normal

operating

condition, more

than 4 times /h is

considered as

If heat load is below the design

operating conditions, re-examine

the conditions and set the control

settings to fewer start/stop times.

For capacity control malfunctions,

see item 10, “Capacity control

malfunction”.

mixed into the

lubricant, resulting

in decreased

For liquid backflow operation,

remove the causes.

For malfunction of oil heater and

other devices on control circuit,

Refer to Factor “Insufficient

refrigerant circulation volume” in

High supply oil

temperature

Refer to the Direct cause “High

supply oil temperature” in item 06.

Loading...

Loading...