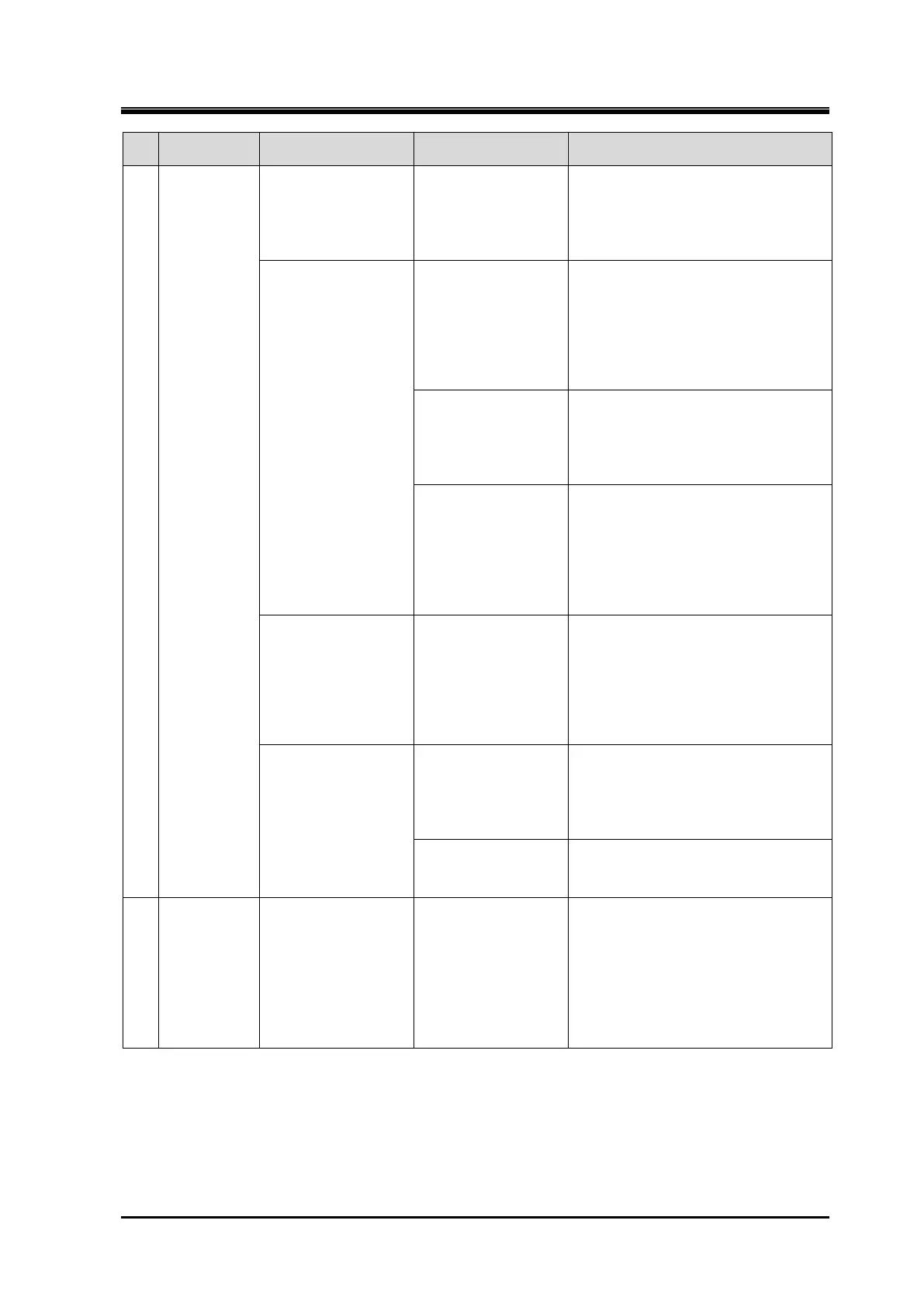

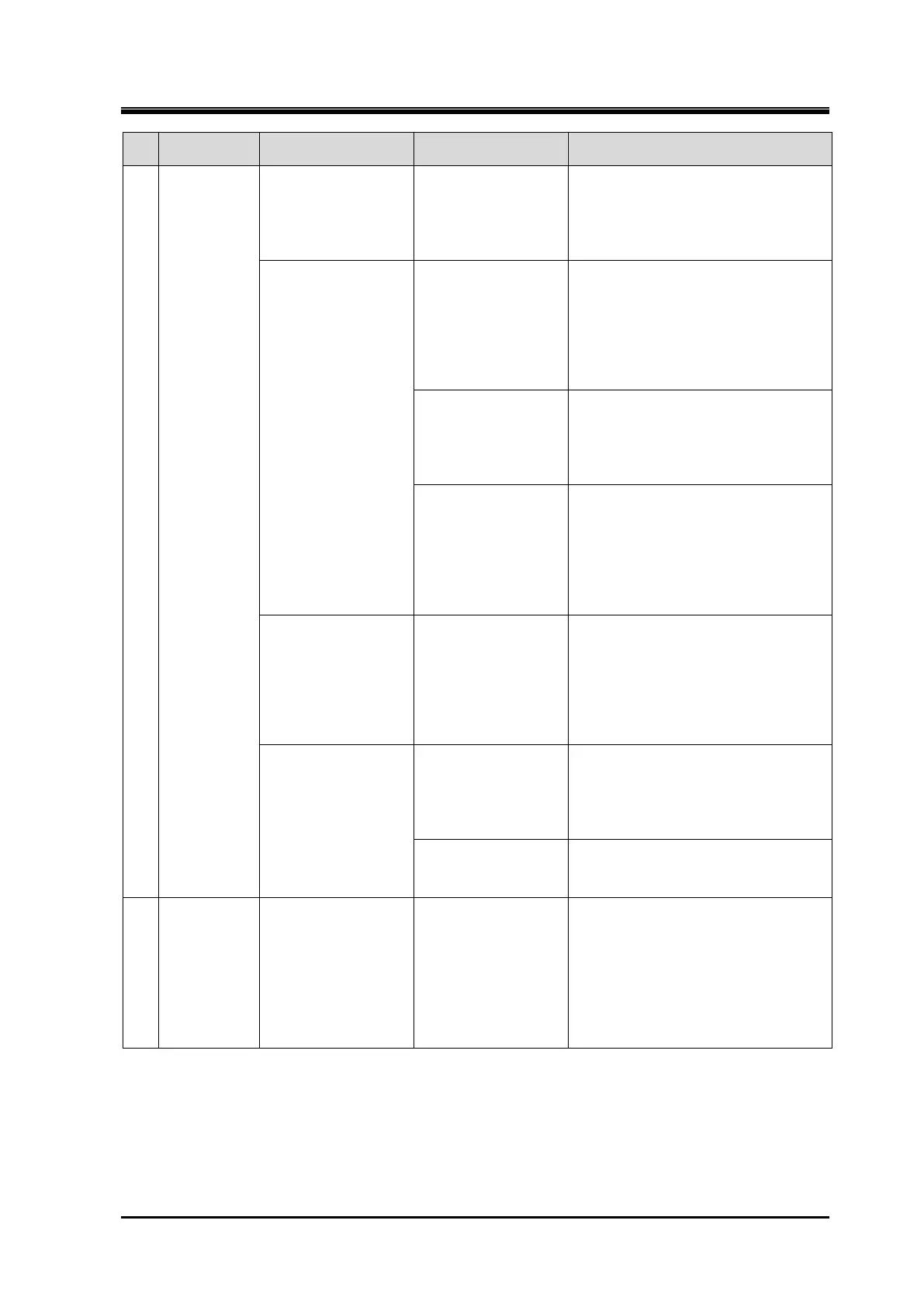

Chapter 6 Troubleshooting

UD-series Screw Compressors

6-6

Trouble Direct causes Factors Actions

mechanical

seal

period (no oil film

on sliding surfaces)

specific conditions,

such as heat load

being intermittent.

If stoppage period becomes more

than one week, manually operate oil

pump as well as manually turn

compressor rotor shaft, or equip

external seal portion with oil pot.

For aging degradation, replace

O-ring.

For other specific causes, the same

factors and actions described above

of “Damaged sliding surface due to

excessive heat of sliding surface”

* Occurs in

excessive

refrigerant

For liquid backflow operation,

remove the causes.

For malfunction of oil heater and

other devices on control circuit,

ring or mating ring

For aging degradation, replace

parts.

For other specific causes, the same

factors and actions described above

of “Damaged sliding surfaces due to

excessive heat of sliding surface”

between operating

conditions (working

temperature

ranges, refrigerant,

etc.) and lubricant

cant or change in

operating

conditions since

installation of

compressor.

Re-examine operating conditions if

possible.

If not, refer to Chapter 4.1,

“Lubricant (Refrigerant Oil)”, and

re-select lubricant and replace all

amount of current lubricant with new

contact conditions

of sliding surfaces

attached to sliding

surfaces due to

contamination of

Equip oil supply line with bypass

filter.

ment

Overhaul compressor to replace

parts, and reassemble it.

Check using assembly check sheet.

sound from

mechanical

seal part

after replacement

until sliding surface

fits each other,

squeaking sound

caused by contact

of sliding surfaces

high in hardness as

well as in density,

so it takes a while

for them to fit each

other.

Squeaking itself does not cause

seal leak or functional deterioration

of seal.

Squeaking normally subsides after

few dozens of hours, but it could

continue in rare cases.

→

In this case, contact our service

Loading...

Loading...