Chapter 6 Troubleshooting

UD-series Screw Compressors

6-7

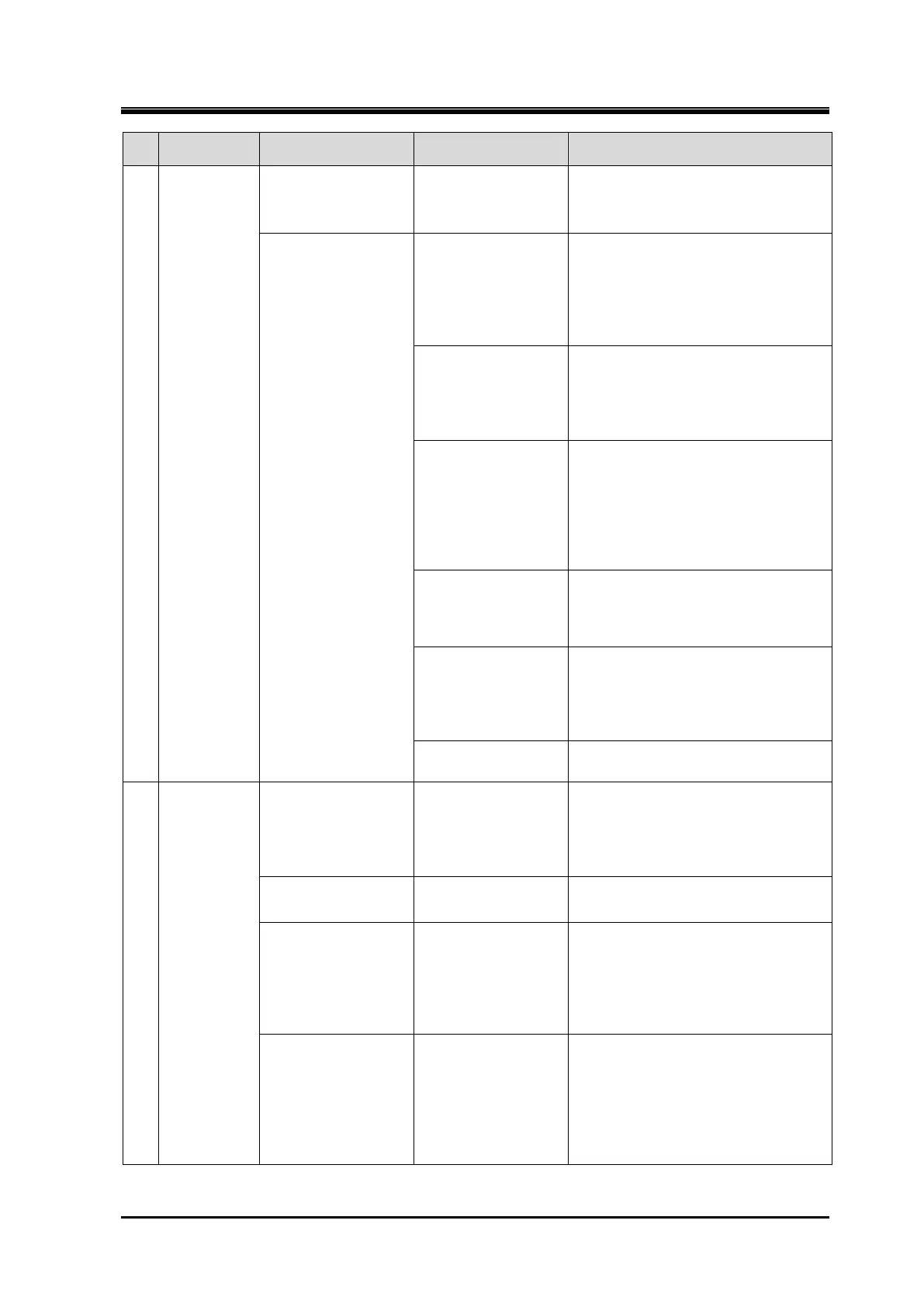

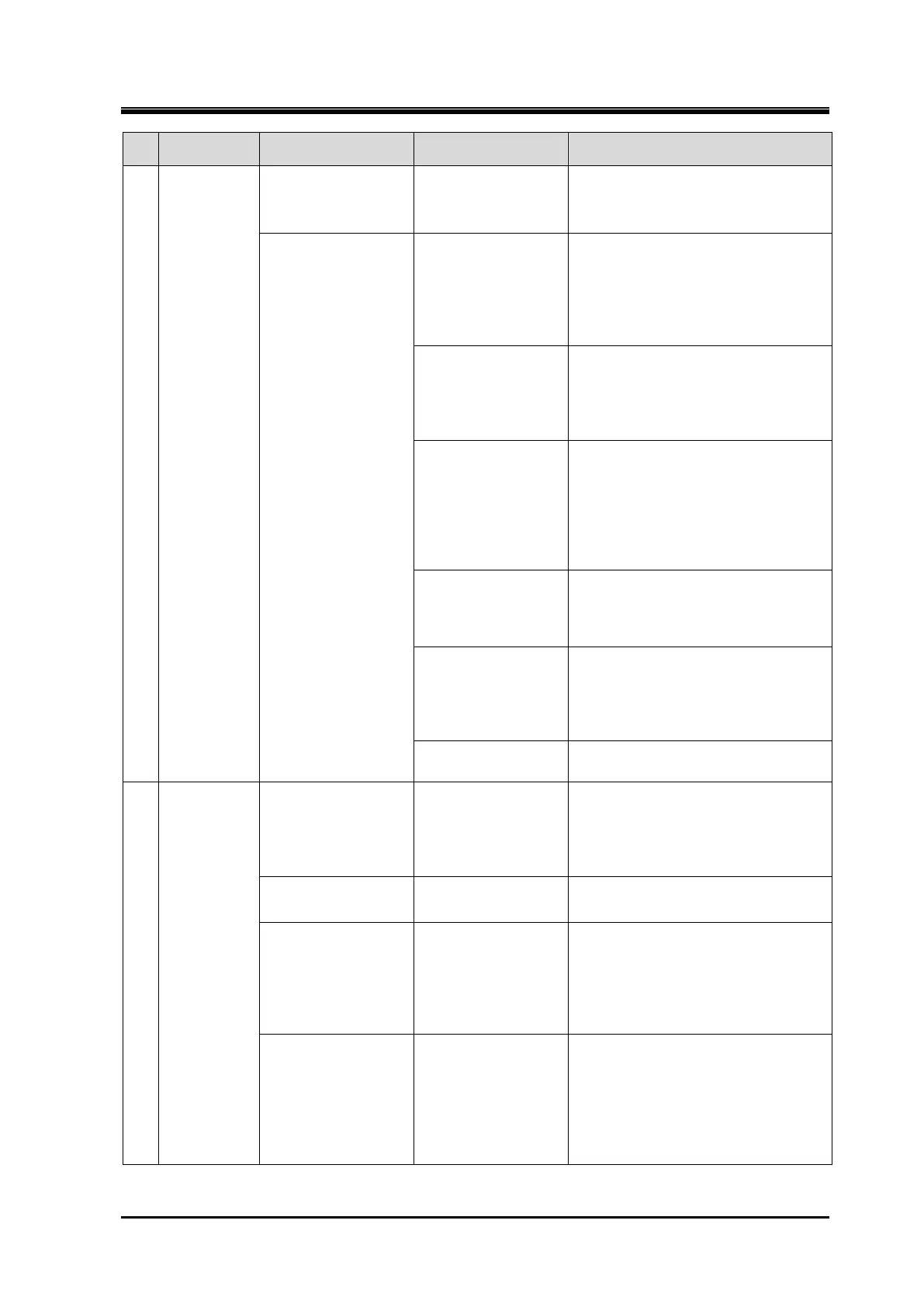

Trouble Direct causes Factors Actions

indication of

capacity

control posi-

tion

compressor

indicator

indicator

Manually tighten screws to the 0%

indication position of compressor

capacity control.

controller capacity

control indicator

compressor

indicator cam

Most cases are due to prolonged

partial load operation. In this case,

replace indicator cam.

* Indicator cam that is currently

manufactured has reinforced

(dowel pin) of com-

pressor push rod

Guide pin of compressor push rod is

currently reinforced as well.

However, if only indicator cam has

reinforced groove, wear of guide pin

might occur. Replace dowel pin.

potentiometer

If cased by aging degradation or

prolonged partial load operation,

replace potentiometer.

If cased by excessive vibration of

compressor, take vibration

reduction measures, and then

zero point and span

adjustment for E/E

positioner or its

indicator

For aging degradation, replace E/E

positioner.

For unique causes such as surge

current, remove the causes or take

Loose terminals or

faulty wiring

For loose terminals, tighten them.

For faulty wiring, replace it.

control

malfunction

in “Imprecision in

controller capacity

control indicator”

or 0% by indicator

micro-switch

unloader solenoid

valves or related

relays, etc. for

capacity control

to coil burnout.

For aging degradation, replace

parts.

For water leakage, etc., remove the

cause and replace parts.

Refer to the solenoid valve

instruction manual for details.

unloader solenoid

valves for capacity

control

refrigerant liquid

trapped inside

unloader cylinder

due to temperature

increases.

If caused by prolonged low load

operation, improve by re-examining

the operation method.

Install a capacity control hydraulic

line with an in-line check valve

(internal reversal-stoppage valve)

Loading...

Loading...