4 • SCREENGUARD AUTOMATIC SCREEN FILTERS OPERATION INSTALLATION AND MAINTENANCE GUIDE

• Prior to installation or handling of the filter, read carefully the installation and operation instructions carefully.

• Confirm filter draining prior to service.

• Take precautions while lifting, transporting or installing the filter.

• Installation of the filter should be performed so as to avoid direct water splashing on any of the filter parts and

especially on the electronic control unit.

• Confirm that filter weight, when full, meets the support construction requirements.

• Prior to installation confirm that line pressure matches filter’s operational pressure.

• During installation, use standard flanges and connections only.

• Check that all filter flange bolts are properly secured.

• Please note, the filter enters a flushing mode automatically, without prior warning.

• Use original parts only when servicing the filter.

• NETAFIM can not accept responsibility for any changes or modifications to the equipment.

SPECIFICATIONS

GENERAL INFORMATION

• Minimum operating pressure: 30 psi

• Maximum Operating Pressure: 150 psi

• Maximum Water Temperature: 149˚ F (65˚ C)

• End Connections: Flanged

• Screen Mesh Sizes: 080, 120, 150, 200

• Sizes: 4”, 6”, 8” and 10”

• Control voltage: DC Latching

• Filter housing: baked epoxy, carbon steel coated

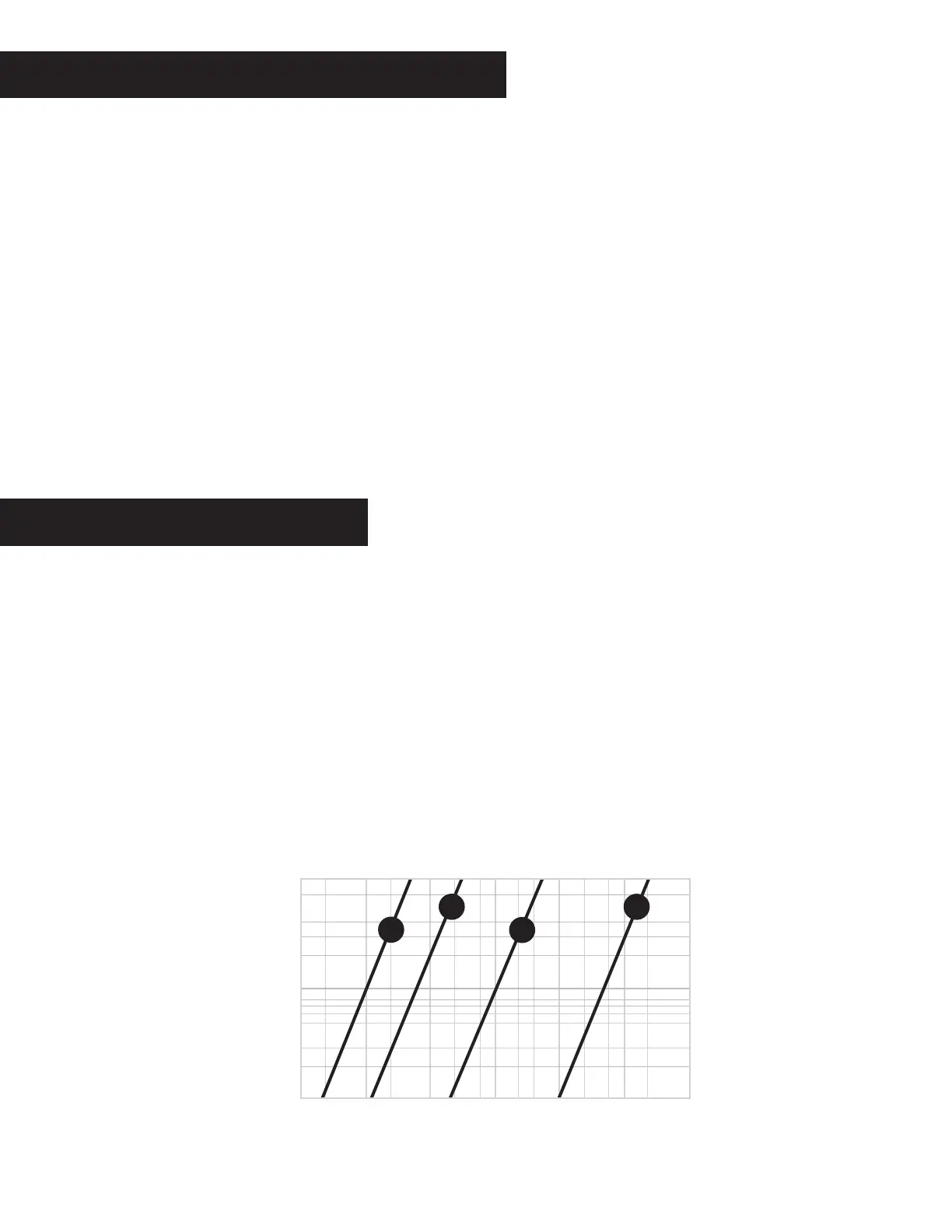

HEADLOSS (FLOW VS. PRESSURE)

1,000 2,000 2,5001,500450

0.14

14

1.4

FLOW RATE (GPM)

PRESSURE (psi)

10"

8"

6"

4"

Loading...

Loading...